Wholesale Jig Checking Fixture - Professional Body Front Panel Checking Fixture Design And Manufacture – TTM

Wholesale Jig Checking Fixture - Professional Body Front Panel Checking Fixture Design And Manufacture – TTM Detail:

Description

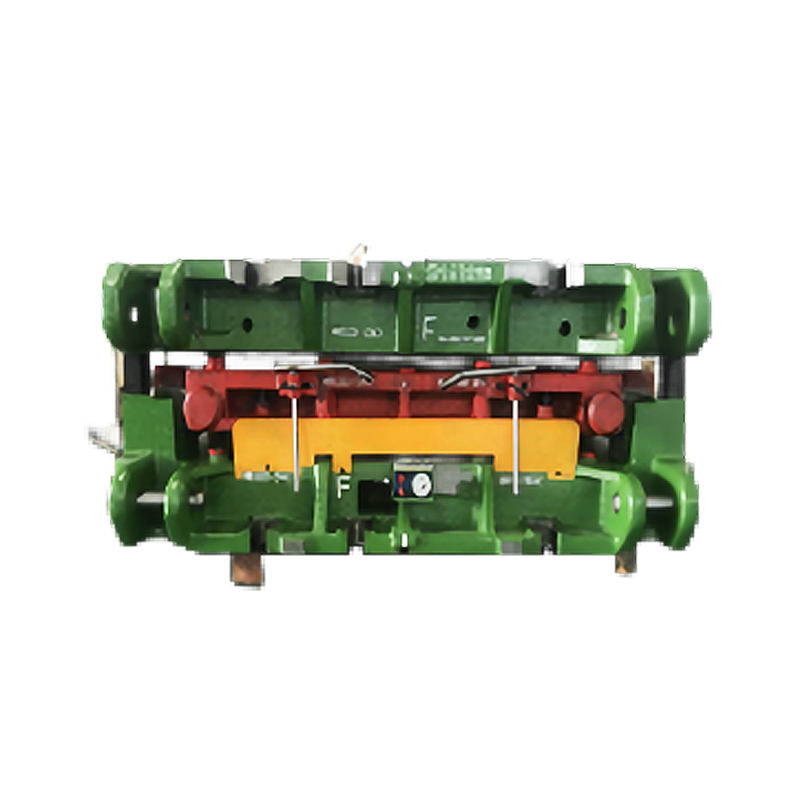

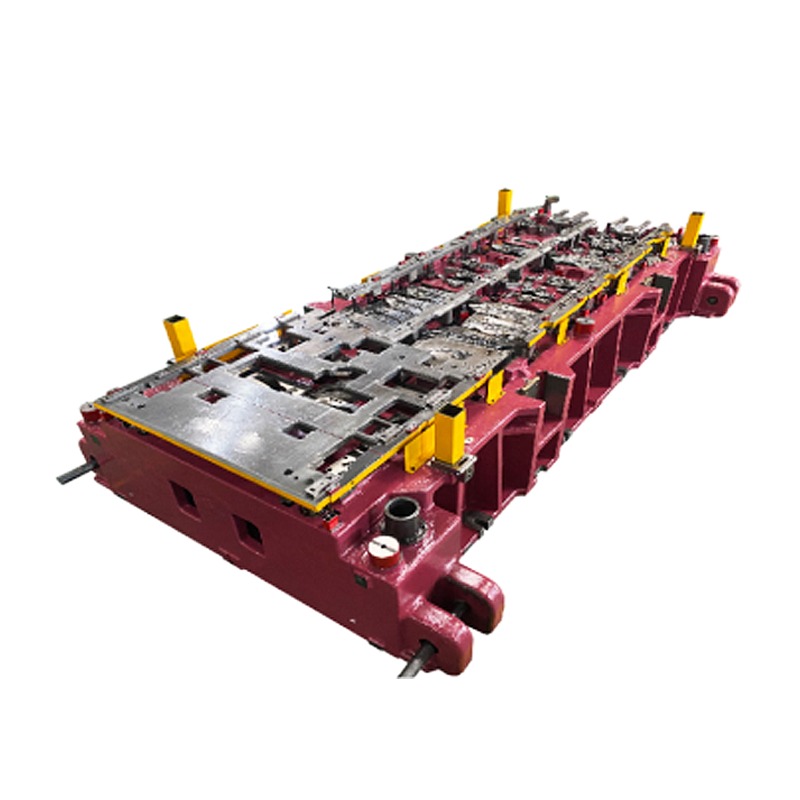

This is a Checking Fixture which will be used to Body Front Panel

This is a Checking Fixture we made for our Germany customer.

Function

For Body Front Panel quality inspection control and support to improve the automotive production line capacity rate

Application fields

Automotive industry quality control

Automotive production line production capacity improve

Specification

| Fixture Type: | Body Front Panel Checking Fixture |

| Size: | 2650x950x1470 |

| Weight: | 2050 KG |

| Material:

|

Main Construction: metal Support: metal

|

| Surface treatment:

|

Base Plate: Electroplating Chromium and Black Anodized |

Detailed Introduction

bj430 checking fixture has high measurement accuracy, no fear of deformation, low maintenance cost and good convenience. Key product characteristic inspection, characteristic line inspection, function hole inspection, area detection which is prone to deformation in assembly process, for automobile assembly and production function matching inspection. In the production process of automotive parts, on-line inspection of automotive parts is realized, which ensures the rapid judgment of the quality status of automotive parts in production, ensures the safety and processing speed of automotive assembly, and improves the quality of automotive parts.

The working flow

Received the purchasing order and Data/Standard/Requirement-> Design->Review and approve design with customer->Prepare the materials->CNC->CMM->Assembling ->CMM->Inspection(Dry fit)->(3rd part inspection if need)-> Buyoff(internal/customer on site)->Packing(wooden box)->Delivery

Manufacturing tolerance

1.The Flatness of Base Plate 0.05/1000

2.The Thickness of Base Plate ±0.05mm

3.The Location Datum ±0.02mm

4.The Surface ±0.1mm

5.The Checking Pins and Holes ±0.05mm

Process

CNC Machining(Milling/Turning), Grinding

Electroplating Chromium and Black Anodized Treatment

Design Hours(h):40h

Build Hours(h):150h

Quality Control

CMM (3D Coordinate Measuring Machine), Vms-2515G 2D Projector, HR-150 A Hardness Tester

Third Party Certification done by ShenZhen Silver Basis Testing Technology Co., Ltd , ISO17025 Certified

Lead time & Packing

45 days after 3D design approved

5 days via express: FedEx by Air

Standard Export Wooden Case

We will add fixing wooden block inside cases to make sure fixture safety in shipping. Desiccant and plastic wrap will be used to keep the checking fixture from moisture in shipping.

Product detail pictures:

Related Product Guide:

Our enterprise insists all along the standard policy of "product high-quality is base of business survival; client satisfaction could be the staring point and ending of an business; persistent improvement is eternal pursuit of staff" as well as consistent purpose of "reputation first, client first" for Wholesale Jig Checking Fixture - Professional Body Front Panel Checking Fixture Design And Manufacture – TTM , The product will supply to all over the world, such as: Zimbabwe, Jeddah, Amsterdam, In the new century, we promote our enterprise spirit "United, diligent, high efficiency, innovation", and stick to our policy"basing on quality, be enterprising, striking for first class brand". We would take this golden opportunity to create bright future.

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.

1.png)

.png)

.png)