Wholesale Dealers of Single Parts Checking Fixture - Auto Trunk Lid Final checking and matching Fixture – TTM

Wholesale Dealers of Single Parts Checking Fixture - Auto Trunk Lid Final checking and matching Fixture – TTM Detail:

Function

As a part of the car interior, the car luggage cover plate is installed on the spare tire slot in the trunk, which plays a supporting and beautiful role. The trunk of the car plate in the process of production and processing, its size and shape flat surface flatness is the key indicators of its product quality, therefore, provides a simple and reasonable structure, both can guarantee accuracy, and can improve the detection efficiency of the fixture, for car trunk cover plate production and processing is necessary.

Application field

Automotive industry quality control.

Automotive production line production capacity improve.

Product Details

Specification

|

Fixture Type: |

Auto Trunk Lid Final Fixture Part |

|

Size: |

5850x950x4300 |

|

Weight: |

3750 KG |

|

Material: |

Main Construction: metal Support: metal |

|

Surface treatment: |

Base Plate: Electroplating Chromium and Black Anodized |

Detailed Introduction

Auto Trunk Lid Final checking and matching Fixture relates to the field of automobile parts production and processing equipment, in particular to a checking tool for automobile trunk cover plate.

At present, with the upgrading and transformation of industrial intelligence, a large number of industrial automation equipment is widely used in automobile, electronics, high-end equipment and other industrial factories and digital workshops, which has become the inevitable trend of enterprise development. In today’s society, people are increasingly pursuing environmental protection, energy saving, aesthetic, lightweight and personalized. Automobile interior parts, like the appearance of automobiles, have become the influencing factors of people’s purchase.

As a part of the car interior, the auto trunk lid is installed on the spare tire slot in the trunk, which plays a supporting and beautiful role. The trunk of the lid in the process of production and processing, its size and shape flat surface flatness is the key indicators of its product quality, therefore, provides a simple and reasonable structure, both can guarantee accuracy, and can improve the detection efficiency of the fixture, for car trunk Lid production and processing is necessary.

In line with the principle of the car trunk lid inspection tools, to ensure the detection accuracy, while saving manpower, improve work efficiency.

The utility model provides a new infrastructure as follows:

The upper surface of the bottom plate is provided with two groups of X direction simulation blocks and two groups of Y direction simulation blocks along the X axis direction and Y axis direction respectively. Four groups of simulation blocks are connected with the end of the enclosure workpiece placement area. Each group of simulation blocks are fixed with a horizontal direction of the first dial indicator and a vertical direction of the second dial indicator, the four corners of the bottom plate are fixed .

The Working Flow

1. Received the purchasing order -——-> 2. Design -——-> 3. Confirming the drawing/solutions -——-> 4. Prepare the materials -——-> 5. CNC -——-> 6. CMM -——-> 6. Assembling -——-> 7. CMM-> 8. Inspection -——-> 9. (3rd part inspection if need) -——-> 10. (internal/customer on site) -——-> 11. Packing(wooden box) -——-> 12. Delivery

Lead time & Packing

45 days after 3D design approved

5 days via express: FedEx by Air

Standard Export Wooden Case

We will add fixing wooden block inside cases to make sure fixture safety in shipping. Desiccant and plastic wrap will be used to keep the checking fixture from moisture in shipping.

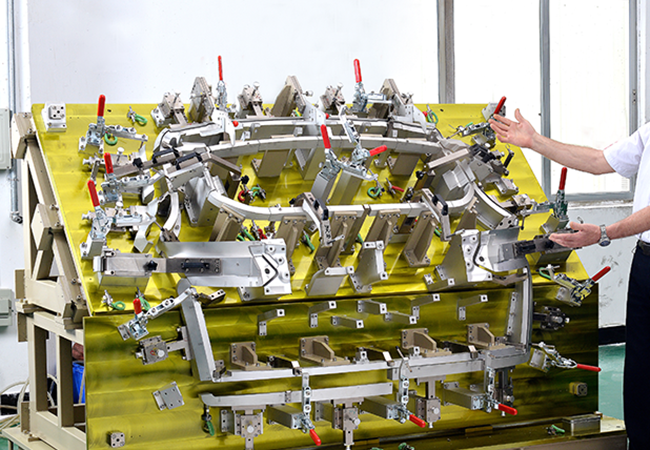

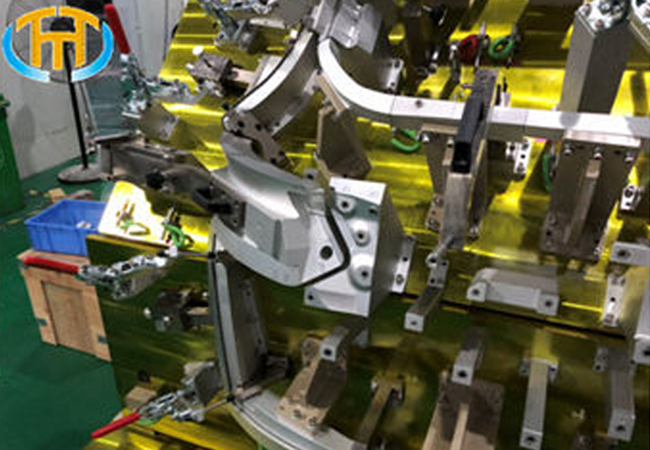

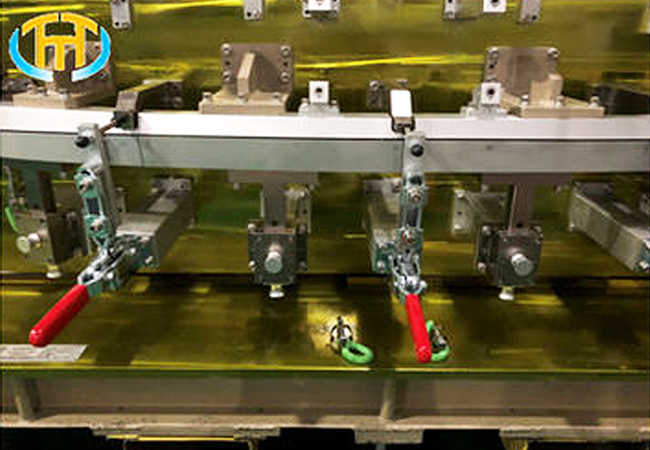

Product detail pictures:

Related Product Guide:

Our business sticks for the basic principle of "Quality could be the life with the firm, and track record will be the soul of it" for Wholesale Dealers of Single Parts Checking Fixture - Auto Trunk Lid Final checking and matching Fixture – TTM , The product will supply to all over the world, such as: Benin, Croatia, Mumbai, Based on our guiding principle of quality is the key to development, we continually strive to exceed our customers' expectations. As such, we sincerely invite all interested companies to contact us for future cooperation, We welcome old and new customers to hold hands together for exploring and developing; For more information, be sure to feel free to contact us. Thanks. Advanced equipment, strict quality control, customer-orientation service, initiative summary and improvement of defects and extensive industry experience enable us to guarantee more customer satisfaction and reputation which, in return, brings us more orders and benefits. If you are interested in any of our merchandise, make sure you feel free to contact us. Inquiry or visit to our company are warmly welcome. We sincerely hope to start a win-win and friendly partnership with you. You can see more details in our website.

The company account manager has a wealth of industry knowledge and experience, he could provide appropriate program according our needs and speak English fluently.

.png)

.png)