Well-designed Adjustable Cylindrical Battery Fixed Clamp Fixture for Spot Welding Machine

It adheres on the tenet “Honest, industrious, enterprising, innovative” to acquire new solutions regularly. It regards shoppers, success as its very own success. Let us establish prosperous future hand in hand for Well-designed Adjustable Cylindrical Battery Fixed Clamp Fixture for Spot Welding Machine, We constantly offer very best high-quality solutions and superb services for your majority of business enterprise users and traders . Warmly welcome to join us, let’s innovate with each other, and fly dreams.

It adheres on the tenet “Honest, industrious, enterprising, innovative” to acquire new solutions regularly. It regards shoppers, success as its very own success. Let us establish prosperous future hand in hand for China 18650 Fixture and 26650 Fixture, Being guided by customer demands, aiming at improving the efficiency and quality of customer service, we constantly improve solutions and provide more in depth services. We sincerely welcome friends to negotiate business and start cooperation with us. We hope to join hands with friends in different industries to create a brilliant future.

Video

|

Base Supporter: |

Steel |

Base Material: |

Al |

|

Size: |

1130*980*1030 Mm |

Weight: |

630KG |

|

Location Datum: |

±0.05mm |

Software: |

Catia, UG, CAD, STP |

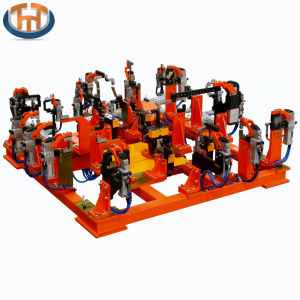

Front Cover Of Automotive Special Automized Welding Jig Fixture

Datum Pins will be spring loaded taper pins where possible, concerned engineer needs to be consulted if designer intent to have it any other kind. All tapered datum pins must check off shear where possible, have angle between 5-10º and make sure part located and secure properly.

These locators should have a good slide action with no side play. Spring force should be appropriate to provide a good positive location. Before clamping taper locators should hold part level and part should be held 2mm to 5 mm above the datum surface.

All features (holes, slots, extruded dimples etc) with size tolerance specified on the drawing must have Go/NoGo pins. Go/NoGo pins must be “Progressive” stepped “Go” then “Go/NoGo” on the same side of the pin. Pins for slots (Round or square type slots) must be separate for width and length.

All Go/No Go Pins must be set into suitable holders and should be base mounted (except for the features like extruded Dimples where difficult to see it clearly while mounted on the base) and located over the perimeter of the base. Design will allow the removal of a pin should it become necessary to repair or replace.

Each holder should have a ‘letter’ for identification label; Eurospec will identify the sizes in their Fixture instructions.

Our production detail

| Items | ||

| 1 | Base Material | Al |

| 2 | Application | Stamping Parts |

| 3 | Surface treatment | Oxidation/Paint |

| 4 | Processing Precision | 0.15 |

| 5 | Accuracy for Other Profiles | 0.1 |

| 6 | Accuracy for Datum Hole | ±0.05 |

| 7 | Certificate | ISO 9001:2008 |

| 8 | CMM certification | Yes |

| 9 | Software | Catia, UG, CAD, STP |

| 10 | Specification | 630KG |

| 11 | Packing | Wooden Box |

Material

Base Plate: Aluminium

Main Base Frame:Steel

Components: Aluminium and Steel with heat treatment

Color

Base Plate Surface: Treated with rust-preventative oil.

Main Base Frame and Supports: Green Color

The Steel and Aluminum Parts: Black Anodized

Manufacturing tolerance

1.The Location Datum ±0.05mm

2.The Surface ±0.15mm

3.The Checking Pins and Holes ±0.1mm

Process

CNC Machining(Milling/Turning), Grinding

Black Anodized Treatment

Design Hours(h): 60h

Quality Control

CMM (3D Coordinate Measuring Machine), HR-150 A Hardness Tester

Lead time & Packing

2 months after 3D design approved

15 days via sea: HMM

Standard Export Wooden Case

Quality Policy

Legal Compliance

Customer First

Total Quality Control

System Operation

Continuous Improvement

More

We’re dedicated to providing our customers with high quality, practical, and cost-effective solutions that serve a variety of needs in the areas of checking fixtures, welding fixtures and jigs! We will work closely with customers to define their needs and assess critical design factors such as functionality, productivity requirements.

It adheres on the tenet “Honest, industrious, enterprising, innovative” to acquire new solutions regularly. It regards shoppers, success as its very own success. Let us establish prosperous future hand in hand for Well-designed Adjustable Cylindrical Battery Fixed Clamp Fixture for Spot Welding Machine, We constantly offer very best high-quality solutions and superb services for your majority of business enterprise users and traders . Warmly welcome to join us, let’s innovate with each other, and fly dreams.

Well-designed China 18650 Fixture and 26650 Fixture, Being guided by customer demands, aiming at improving the efficiency and quality of customer service, we constantly improve solutions and provide more in depth services. We sincerely welcome friends to negotiate business and start cooperation with us. We hope to join hands with friends in different industries to create a brilliant future.

.png)

.png)