Spot Robotic Welding Systems With Fixture Switching Device Advantage For Automotive Parts

Video

Product Details

| Place of Origin: | China |

| Brand Name: | Top Talent |

| Certification: | ISO 9001 2008 Certification |

| Model Number: | TTM18603 System |

Payment & Shipping Terms

| Minimum Order Quantity: | 1 System |

| Price: | All the price can be negotiated |

| Packaging Details: | Depending on your request for High Precision Auto Checking Fixture |

| Delivery Time: | Shipped in 2-3 days after buyoff and payment |

| Supply Ability: | 3000 Piece per annual |

|

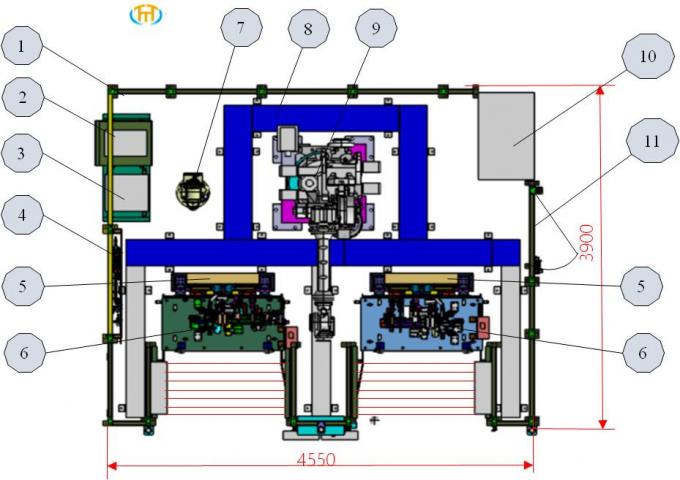

1 Item: |

The Periphery |

2 Item: |

Robot Control Cabinet |

|

3 Item: |

Welding Controol Cabinet |

4 Item: |

Water And Gas Station |

|

5 Item: |

Fixture Switching Device |

6 Item: |

Fixture |

Spot Robotic Welding Systems With Fixture Switching Device Advantage For Automotive Parts

1. The Periphery

2. Robot Control Cabinet + Welding Control Caninet

3. PlC Control Cabinet

4. Water and Gas Station

5. Fixture Switching Device

6. Fixture

7. Electrode Modifier

8. Trunking

9. The Robot Base + Robot

10.Electrical Cabinet

11.Safety Door

12.Valve Control Cabinet

13. Tricolor Indicator Light

14.Safety Grating

15.Touch Screen

16.Button Box

17.Security Door Indicator Light

With simple structure , A switching device is easy to switch, but has relatively low repeating accuracy and high requirements of ground flatness.

Solution is verification with three robots prior to welding.

B Swich Device has similar structure with A mechanism . It is easy to operate and avoid the problem of low repeating accuracy . It has low requirements on the ground flatness but needs a stable air pressure. Air leakage of cylinder and pipe is lethal to this kind of switching device.

Below is a transformation project for LEVDEO D056/D070/SC2 welding assembling line which is undertaken by TTM team. Below the link can help you to know us more .

.png)

.png)