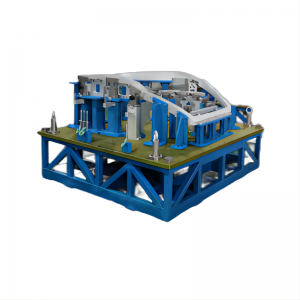

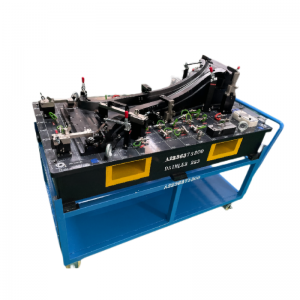

Single Metal Part Checking Fixture

Video

Function

The single metal part checking fixture has high measuring accuracy, not afraid of deformation, low maintenance cost and good convenience. Key product feature inspection,feature line inspection, functional hole inspection, ASSEMBLY process easy to produce deformation of the area detection, used for automobile assembly, production function matching detection. In the process of auto parts production, the online detection of auto parts is realized, so as to ensure the rapid judgment of the quality of auto parts during production, ensure the safety and processing speed of auto assembly, and improve the quality of auto parts.

Based on the principles of all functional parts in single checking fixture,starting with importing the quality requirement of the product,design and application requirements of all functional parts were analysis-ed. According to user's habits and different demands in different areas,suitable standard was chosen to get a high quality single checking fixture with compact structure,convenient operation,which can accurately measure the piecework safety and rapidly.

Application Fields

Automotive industry quality control.

Automotive production line production capacity improve.

Specification

|

Fixture Type: |

Single Metal Part Checking Fixtures |

|

Certification: |

ISO 9001 2008 Certification |

|

Minimum Order Quantity: |

1 Piece |

|

Price: |

All the Price can be negotiated |

|

Packaging Details: |

Depending on your request for High Precision Auto Checking Fixture |

|

Supply Ability: |

3000 Piece per annual |

|

Delivery Time: |

Shipped in 2-3 days after buyoff and payment

|

Specification

1. Received the purchasing order and Data/Standard/Requirement -——-> 2. Design -——-> 3. Review and approve design with customer -——-> 4. Prepare the materials -——-> 5. CNC -——-> 6. CMM -——-> 6. Assembling -——-> 7. CMM-> 8. Inspection(Dry fit) -——-> 9. (3rd part inspection if need) -——-> 10. Buyoff(internal/customer on site) -——-> 11. Packing(wooden box) -——-> 12. Delivery

Product Details

Manufacturing Tolerance

1. The Flatness of Base Plate 0.05/1000

2. The Thickness of Base Plate ±0.05mm

3. The Location Datum ±0.02mm

4. The Surface ±0.1mm

5. The Checking Pins and Holes ±0.05mm

Lead Time & Packing

30 days after 3D design approved

5 days via express: FedEx by Air

Standard Export Wooden Case

We will add fixing wooden block inside cases to make sure fixture safety in shipping. Desiccant and plastic wrap will be used to keep the checking fixture from moisture in shipping.

.png)

.png)