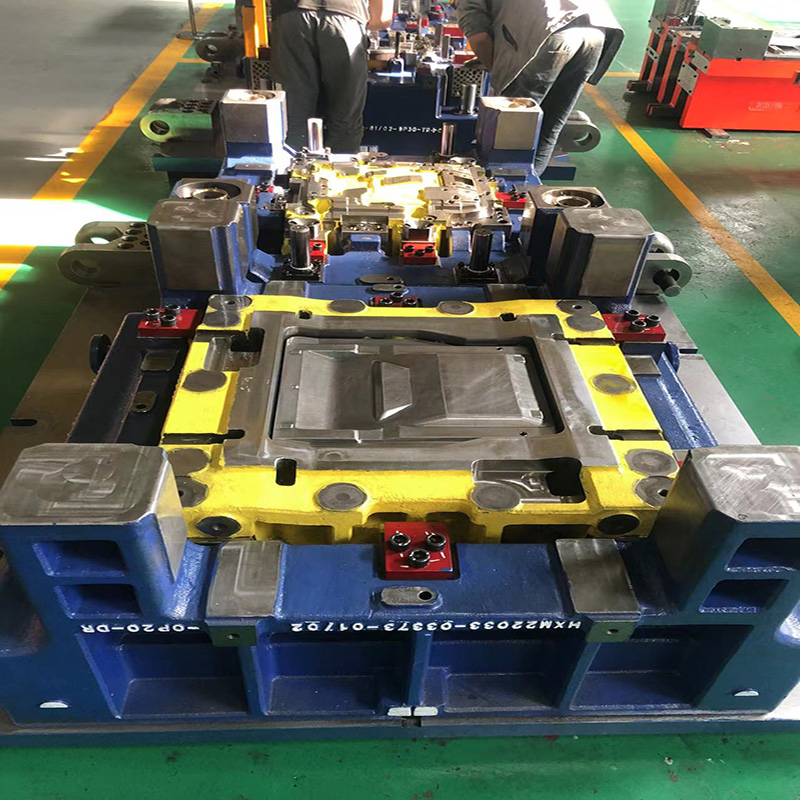

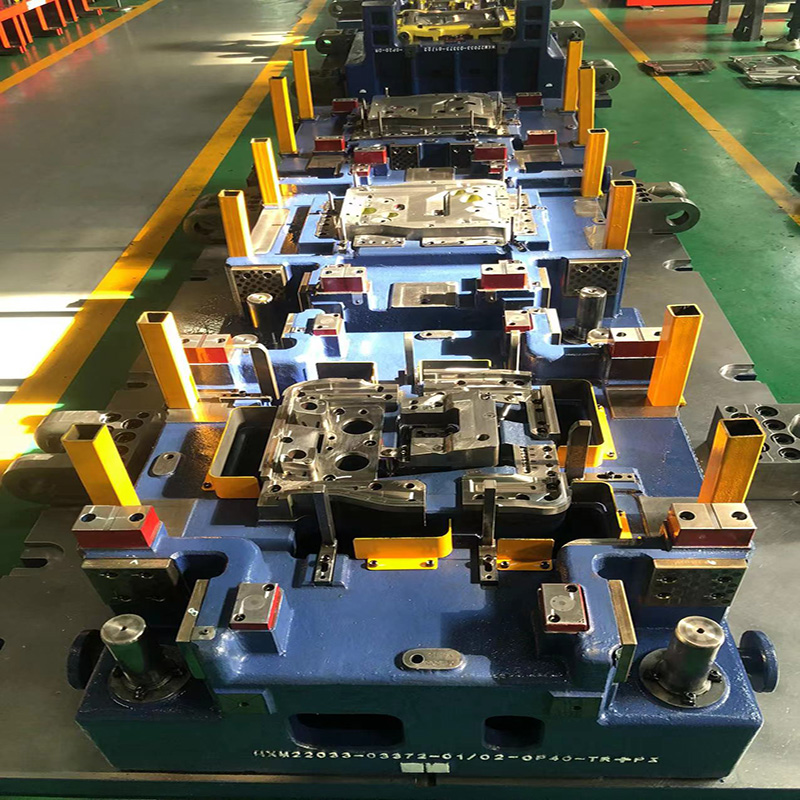

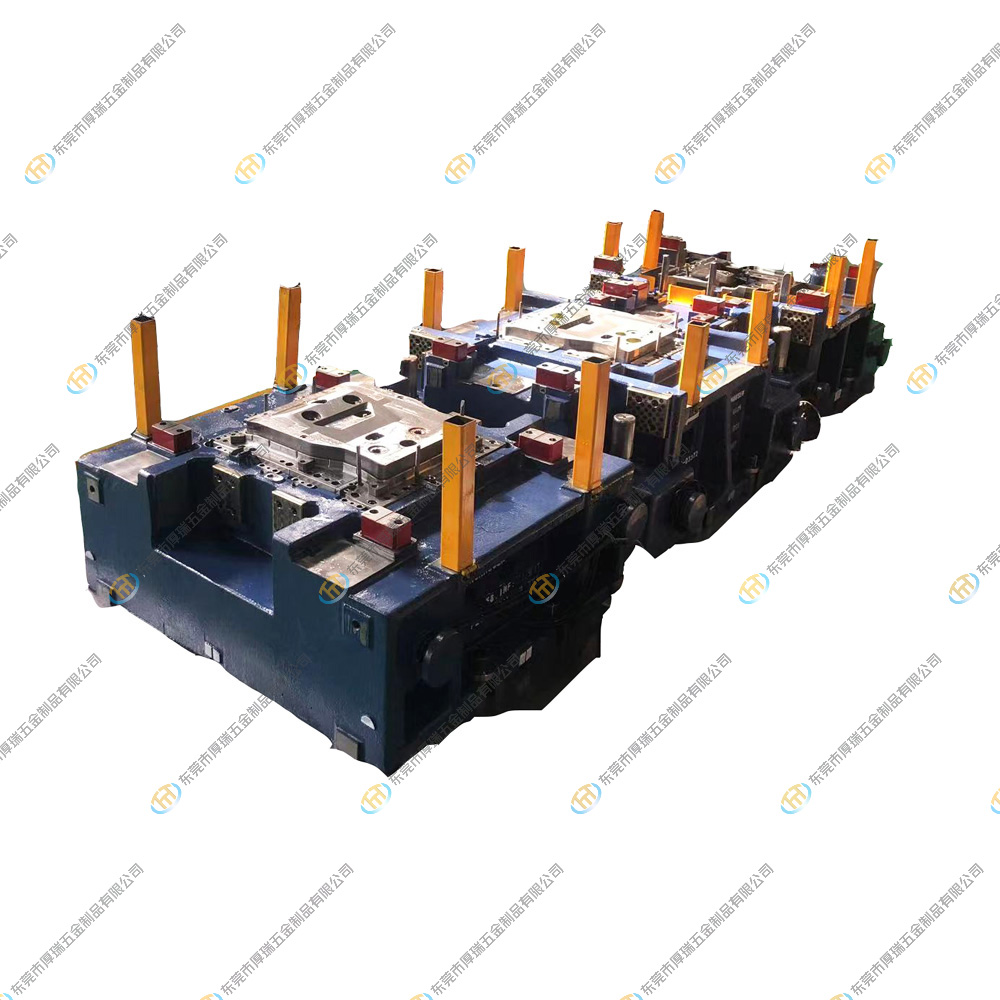

Precision Stamping Dies For Car Seat Part Metal Stamping Die Mold Manufacturers

Video

Product Details

Detailed Introduction

The car seat system The hardware products have high requirements for section bright band, hole position accuracy, turning hole height and peripheral surface appearance. Among them, stamping technology is the key technology in the design of auto parts. The design of TTM car seat part mold stamping die can effectively reduce the cost of products and improve the quality of products , shorten the construction period, etc.

The Working Flow

1. Received the purchasing order -——-> 2. Design -——-> 3. Confirming the drawing/solutions -——-> 4. Prepare the materials -——-> 5. CNC -——-> 6. CMM -——-> 6. Assembling -——-> 7. CMM-> 8. Inspection -——-> 9. (3rd part inspection if need) -——-> 10. (internal/customer on site) -——-> 11. Packing(wooden box) -——-> 12. Delivery

Manufacturing Tolerance

1. The Flatness of Base Plate 0.05/1000

2. The Thickness of Base Plate ±0.05mm

3. The Location Datum ±0.02mm

4. The Surface ±0.1mm

5. The Checking Pins and Holes ±0.05mm

.png)

.png)