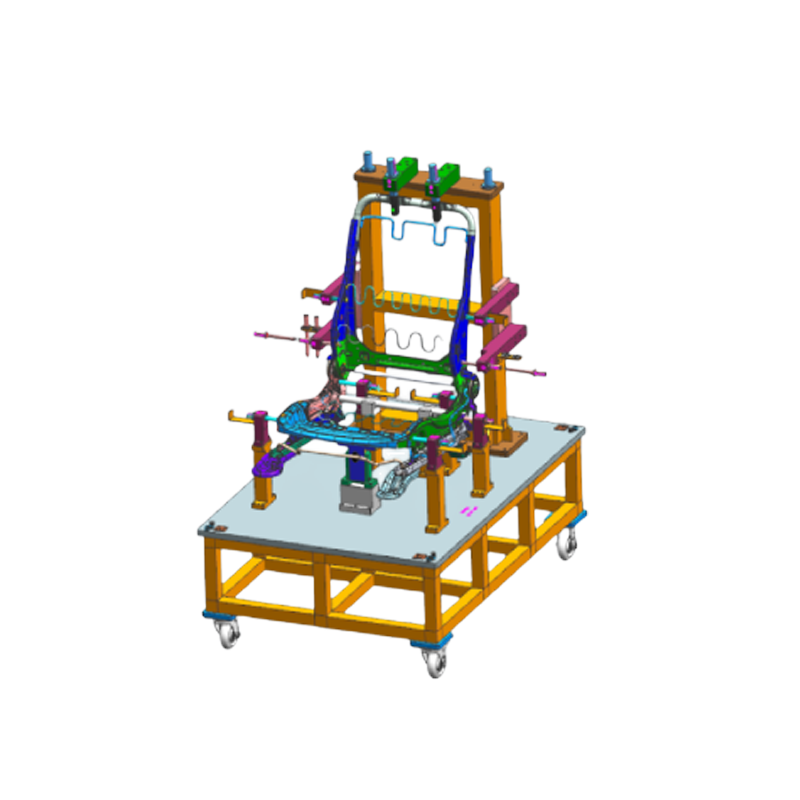

OEM/ODM China Automotive Fixture - Customized good quality seating check fixture service – TTM

OEM/ODM China Automotive Fixture - Customized good quality seating check fixture service – TTM Detail:

Function

For Seat quality inspection control and support to improve the automotive production line capacity rate.

Specification

|

Fixture Type: |

Checking Fixture for Seating |

|

Size: |

1200*900*1900 |

|

Weight: |

1350 KG |

|

Material: |

Main Construction: metal Support: metal |

Product Details

Detailed Introduction

Our factory finished the checking fixture manufacturing, assembly, functional testing, measuring adjustment, and the evaluation of the repeatability and reprehensibility, and materials of the latest state (including fixture assembly diagram, submit the inspection report, submit the repeatability and reprehensibility analysis report, submit instructions) and receive offer seats (including the installation on the fixture body parts), The tester engineer and quality engineer can be informed to make the testing approved.

The testing approval shall be carried out at the supplier of the fixture, with the participation of fixture engineers and quality engineers. The testing approval shall be reviewed according to the approved fixture design scheme, product drawings, fixture technical standards and other documents.

The tester engineer is responsible for summarizing the testing acceptance problems, and the testing supplier will modify the testing according to the testing acceptance problem list, Fixture engineer or related personnel according to submit acceptance issues list to submit acceptance, again by the acceptance problems list, some questions are turned off, the fixture engineer, quality engineer, together with the supplier sign fixture manufacturing checklist (that is, the fixture table B), and submit to OEM fixture engineer the AQE is responsible for the acceptance.

The Working Flow

1. Received the purchasing order -——-> 2. Design -——-> 3. Confirming the drawing/solutions -——-> 4. Prepare the materials -——-> 5. CNC -——-> 6. CMM -——-> 6. Assembling -——-> 7. CMM-> 8. Inspection -——-> 9. (3rd part inspection if need) -——-> 10. (internal/customer on site) -——-> 11. Packing(wooden box) -——-> 12. Delivery

Manufacturing Tolerance

1. The Flatness of Base Plate 0.05/1000

2. The Thickness of Base Plate ±0.05mm

3. The Location Datum ±0.02mm

4. The Surface ±0.1mm

5. The Checking Pins and Holes ±0.05mm

Lead time & Packing

45 days after 3D design approved

5 days via express: FedEx by Air

Standard Export Wooden Case

Product detail pictures:

Related Product Guide:

We have now probably the most innovative production equipment, experienced and qualified engineers and workers, regarded high quality control systems and also a friendly expert income team pre/after-sales support for OEM/ODM China Automotive Fixture - Customized good quality seating check fixture service – TTM , The product will supply to all over the world, such as: Cologne, Jamaica, Porto, Our staffs are adhering to the "Integrity-based and Interactive Development" spirit, and the tenet of "First-class Quality with Excellent Service". According to the needs of every customer, we give customized & personalised services to help customers achieve their goals successfully. Welcome clients from home and abroad to call and inquire!

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.

.png)

.png)