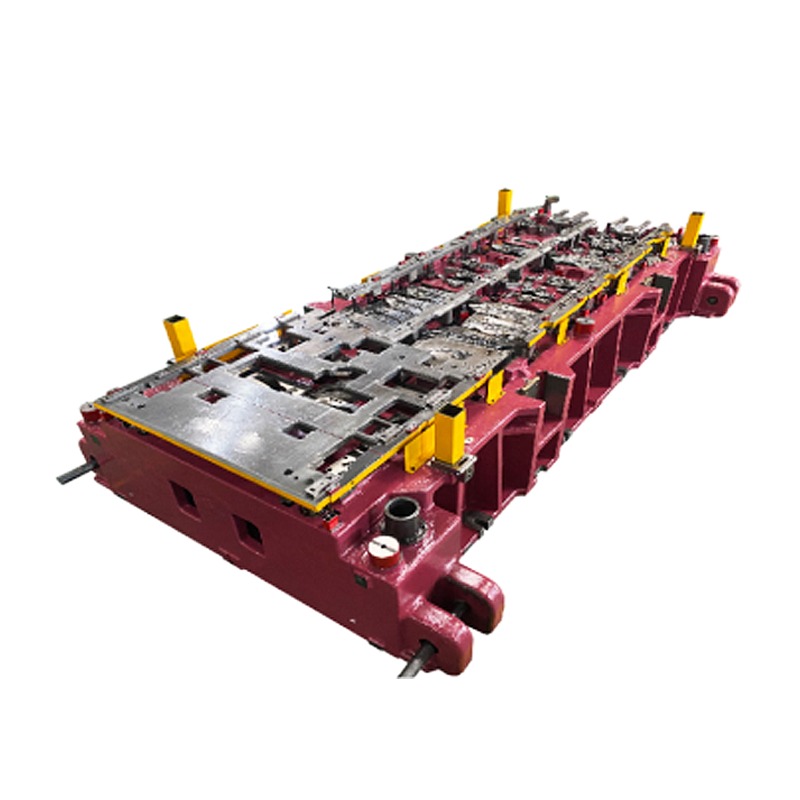

OEM Custom Metal Milling Turning Service Aluminum CNC Machining and Partssurface grinder parts – TTM

OEM Custom Metal Milling Turning Service Aluminum CNC Machining and Partssurface grinder parts – TTM Detail:

Available materials

| Stainless Steel | SS201,SS301, SS303, SS304, SS316, SS416 etc. |

| Steel | mild steel, Carbon steel,12L14, 12L15,4140, 4340, Q235, Q345B, 20#, 45# etc. |

| Brass | HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 etc. |

| Copper | C11000,C12000,C12000 C36000 etc. |

| Aluminum | AL6061, AL6063, AL6082, AL7075, AL5052, A380 etc. |

| OEM | Acceptable |

Surface treatment

| Aluminum parts | Stainless Steel parts | Steel parts | Brass parts |

| Clear Anodized | Polishing | Zinc plating | Nickel plating |

| Color Anodized | Passivating | Oxide black | chrome plating |

| Sandblast Anodized | Sandblasting | Nickel plating | Electrophoresis black |

| Chemical Film | Laser engraving | Chrome plating | Oxide black |

| Brushing | Electrophoresis black | Carburized | Powder-coated |

| Polishing | Oxide black | Heat treatment | |

| Chroming | Powder Coated |

| Production Equipment | 1)CNC Machining Center;2)CNC Lathe;3) CNC Milling Machine;4) Precision Cutting Machine |

| Measuring Instruments and Equipment | 1)micrometer,2)smooth plug gauge,3)thread gauge,4) Image measuring instrument ,5) Coordinate Measuring Machine ,6) Roughness tester ,7) routine inspection of calipers |

| Preferred Drawing Formats | JPEG, PDF,CAD,IGS,STP |

| Preferred Industries | 1) Communication Equipments2) Medical Equipments3) Photoelectricity Equipments4) Auto Industry5) Mechanical Equipments6) Other customized Parts |

| Supply Ability | 30000 Piece/Pieces per Month CNC machining turning parts high demand engineering metal product |

| Drawing Formats | CAD/PDF/DWG/DXF/DXW/IGES/STEP etc. |

| Our Advantages | 1.) 24 hours online service & quickly quote/delivery.2.) 100% QC quality inspection before delivery, can provide quality inspection form. 3.) 14+ years of experience in the CNC machining area and have a senior design team to offer perfect modification suggestions. |

Product Details

Packaging & delivery

1.Paper, EPE Foam, poly bag, pp bag packaged for protecting products.

2.Standard carton boxes or wooden boxes

3.We also can pack and ship according to customer’s specific requirements.

Lead time:

| Quantity(pieces) | 1 - 10 | 11 - 500 | 501 - 1000 | >1000 |

| Est. time (days) | 3 | 7 | 15 | To be negotiated |

Product detail pictures:

.png)

.png)

.png)

.png)

Related Product Guide:

We believe in: Innovation is our soul and spirit. Top quality is our life. Purchaser need is our God for OEM Custom Metal Milling Turning Service Aluminum CNC Machining and Partssurface grinder parts – TTM , The product will supply to all over the world, such as: Palestine, azerbaijan, Mauritania, Customer satisfaction is our goal. We are looking forward to cooperating with you and providing our best services to suit your needs. We warmly welcome you to contact us and make sure you feel free to contact us. Browse our online showroom to see what we can do for you. And then E-mail us your specs or inquiries today.

Good quality and fast delivery, it's very nice. Some products have a little bit problem, but the supplier replaced timely, overall, we are satisfied.

.png)

.png)