Automobile inspection tools refer to special tools and equipment for measuring, inspecting, calibrating and verifying auto parts and bodywork. They are an integral part of the car manufacturing process, ensuring that the car’s quality and performance meet standards and specifications. The following are some knowledge popularization of the automobile inspection tool industry:

1. There are many types of automobile inspection tools, including measuring tools, fixtures, measuring tools, molds, etc. Each type of gage has its specific application and function for inspecting different types of auto parts and bodies.

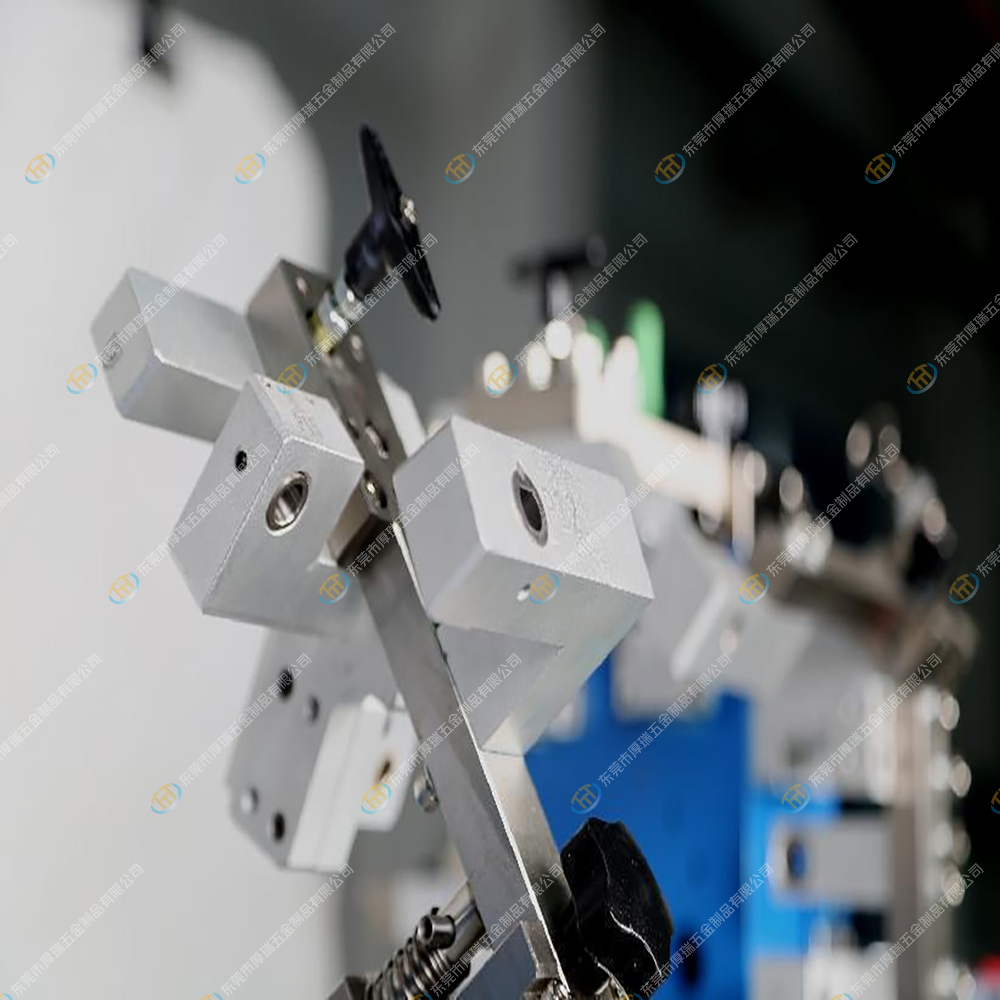

2. The manufacture of automobile inspection tools requires high-precision processing technology and materials. High-precision manufacturing can ensure the accuracy and reliability of inspection tools for accurate measurement and inspection of auto parts and bodywork.

3. Automobile inspection tools need to be calibrated and maintained frequently. Calibration ensures the accuracy and reliability of the gage, while maintenance prolongs the life of the gage and ensures it works correctly.

4. The use of automobile inspection tools needs to follow certain safety regulations and operating procedures. When using inspection tools, operators need to understand relevant safety knowledge and operating procedures to ensure the safety of themselves and those around them.

5. With the continuous development and progress of automobile manufacturing technology, the automobile inspection tool industry is also constantly innovating and developing. For example, TTM is adopting digital technology and intelligent equipment to improve production efficiency and product quality. We always insist on customer first and provide customers with high-quality products and one-stop service solutions.

Post time: May-04-2023

.png)

.png)