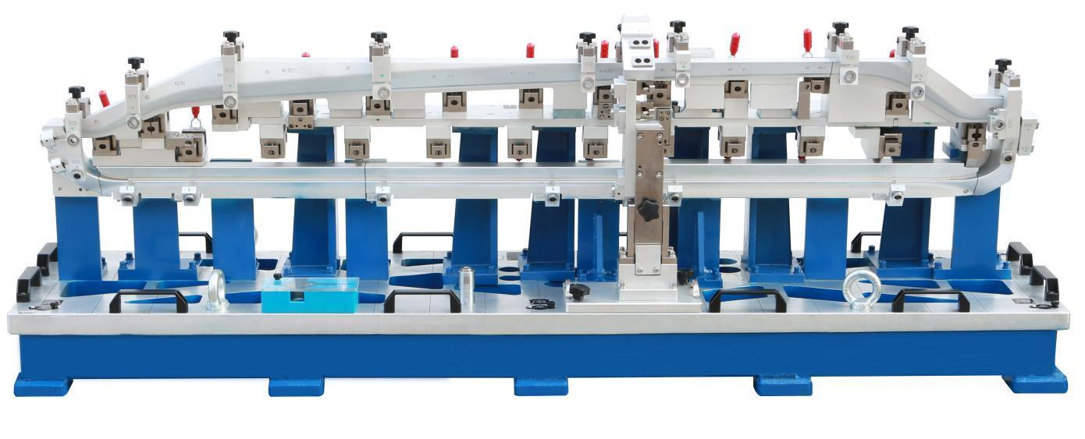

Car manufacturers must use the inspection tools to test the car. The car inspection tool is a special inspection equipment used to measure and evaluate the dimensional quality of the parts. At the production site of the parts, the parts are inspected online by the inspection tool. The parts are accurately mounted on the gage, and then the parts are scanned by visual inspection, or by a measuring gauge, or a caliper, or by inspection pins or by visual inspection of the holes of different nature on the parts . The position is visually inspected to ensure a quick judgment of the quality of the part at the time of production. How does it work after the car inspection tool? This should be what many people want to know.

The working principle of the car inspection tool is to use the high-speed and high-precision vision processing technology to automatically detect various mounting errors and welding defects on the pcb board. The PCB board range can be from fine pitch high density board to low density large size board and provide Online inspection solutions to promote productivity and weld quality, automotive inspection tools use AOI as a tool to reduce defects, find and eliminate errors early in the assembly process to achieve good process control.

For some extremely important functional dimensions on the part, it is also possible to use the gage for numerical detection. Usually, the coordinate value of the part based on the body coordinate system can not be directly obtained by means of the gage, but the part is placed on the gage through three the measurement of the coordinate measuring machine is only obtained. The structure of the modern inspection tool is designed to be used as a measuring bracket at the same time. However, when the online inspection function and the measuring bracket function of the inspection tool cannot be satisfied at the same time, the online inspection function of the inspection tool should be satisfied first.

Post time: Feb-10-2023

.png)

.png)