TTM is a well-established automobile-related manufacturing company that has achieved a high level of automation. We specialize in the production of automotive inspection fixtures, welding fixtures, and moulds. In this article, we would like to introduce the impact of power quality in automotive manufacturing.

The technology and automation level of the automobile manufacturing industry is getting higher and higher, and a large number of impact and nonlinear loads are used in its main production processes, such as electric welding machines and laser welding machines in the body shop, stamping machines in the stamping shop, and frequency conversion devices in the paint shop. , the automatic production line in the assembly workshop, etc., these loads have a common feature, that is, the load fluctuation is very large and the harmonic generation is very large. At the same time, with the continuous requirements of the country to reduce consumption and save energy, a large number of energy-saving lamps are used; traditional motors are gradually replaced by frequency conversion drives. These new non-linear loads exacerbate the deterioration of power quality in the automotive manufacturing industry.

Current energy problems

Through the statistical analysis of power quality testing, it is found that the main power quality problems in the automobile manufacturing industry are harmonics, voltage fluctuations and reactive power problems, which generally exist in various links such as stamping, welding, painting, powertrain and final assembly.

1. Stamping workshop – harmonics, voltage fluctuations and flicker

The sensitive loads in the stamping workshop are mainly concentrated on the presses, including robots and DC power supplies. Many presses are driven by DC speed-adjustable motors and require a stable DC power supply. Robot motors are controlled by PLC and driven by frequency converters. PLC control circuits and frequency converters are both is a typical sensitive load.

2. Paint shop – harmonic

The paint surface of the car is divided into four layers, primer, intermediate coat, base coat and varnish. Except that the primer needs to be attached to the battery pool, the other processes are basically similar. The automatic spraying workshop is a production workshop with a relatively high process chain. The failure of individual equipment It will affect the entire spray shop process.

3. Powertrain

The powertrain mainly refers to engine production, and the impact of electric energy is concentrated on the CNC machine tools in the machining workshop, as well as conveying equipment, assembly lines, and test platforms. Expensive and complex equipment downtime requires resetting machine parameters, scrapping workpieces, damaging tools, stopping production lines, waiting for work, etc.

4. Final Assembly – Harmonics

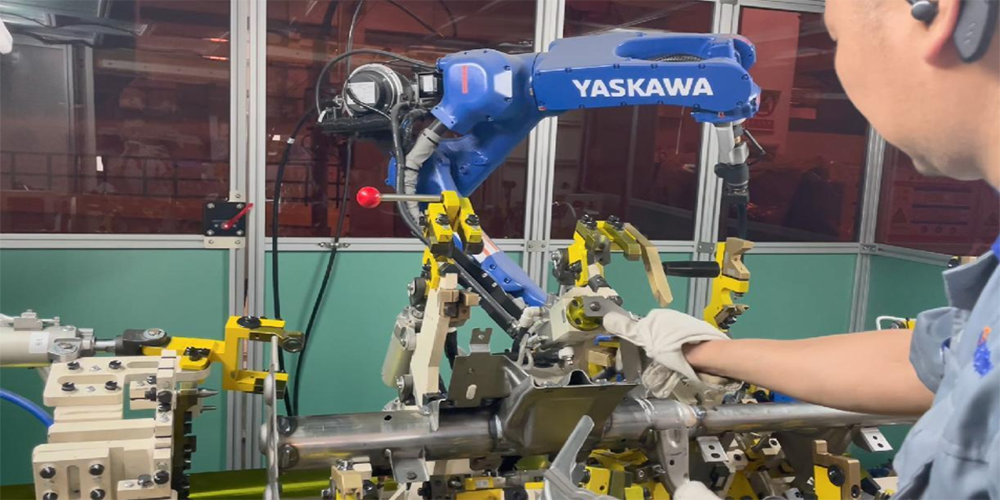

The final assembly process mainly uses robots for automatic assembly, and a large number of electronic components such as diodes, triodes, amplified currents, rectifier bridges, and switching power supplies are used in the circuits driving the robots. The superposition of a large number of harmonics will not only seriously affect the power supply system, but also It is fatal to damage the life and operation precision of the robot.

Post time: May-17-2023

.png)

.png)