TTM is a manufacturer focusing on automotive fixtures, automotive inspection fixtures, automotive molds and CNC machining parts. Our company was established in 2011 and is headquartered in Dongguan City, Guangdong Province, China. As a professional manufacturer, TTM has rich experience and innovative ability, and is committed to using the best quality materials and processes to produce high-quality fixtures, inspection fixtures, molds and processed parts.Today in this article,we want to share that What are the design principles of stamping parts processing?

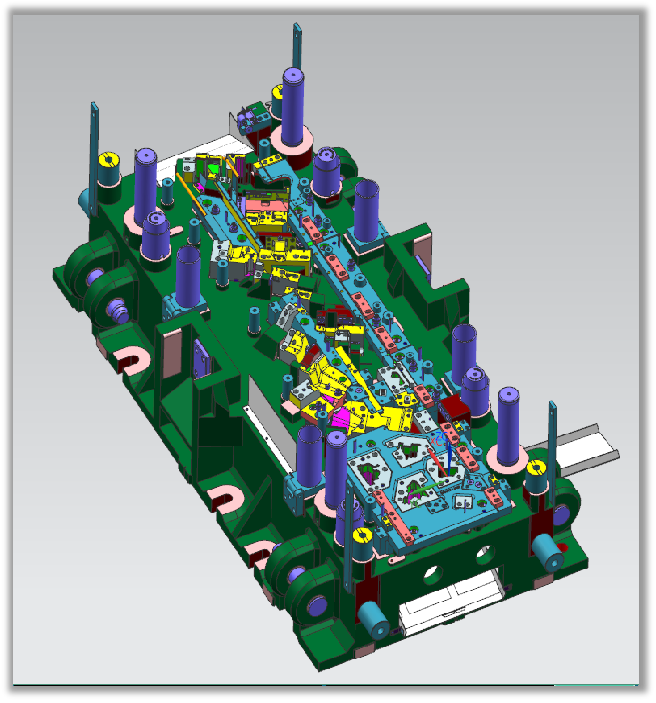

stamping die maker

stamping die maker

Stamping is one of the production processes for mass production of parts. Die failure is the most likely problem in stamping production, which often causes production stoppage and affects the product production cycle. Therefore, the cause of mold failure must be found as soon as possible and repaired reasonably.

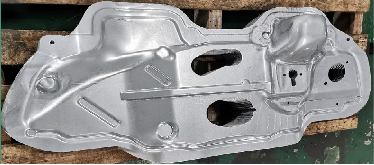

stamping die manufacturer

stamping die manufacturer

Stamping parts processing design principles

First of all, the stamping parts designed must satisfy the use and technical performance of the product, and be easy to assemble and repair;

Then it must be conducive to improving the utilization rate of metal materials, reducing the variety and specifications of materials, reducing material consumption as much as possible, using low-cost materials where allowed, and making parts as waste-free and as little as possible.

When designing, the shape must be simple and the structure must be reasonable, which is conducive to the structure of the mold, simplifies the number of processes, and completes the processing of the entire part with the least and simplest stamping process, and is conducive to stamping operations and facilitates organization. Realize mechanized and automated production to improve labor productivity.

At the last,when designing stamping parts, under the condition of ensuring normal use, try to make the dimensional accuracy level and surface roughness level as low as possible, which is conducive to product interchange, reduces waste products, and ensures stable product quality; it should be conducive to using existing products as much as possible. It is processed by equipment, process equipment and process flow, and it is beneficial to prolong the service life of the die.

Post time: Apr-17-2023

.png)

.png)