Steel stamping dies play a crucial role in manufacturing, serving as the backbone for producing metal parts across various sectors, from automotive to electronics. These specialized tools transform flat steel sheets into complex shapes with precision and efficiency. This article will delve into the intricacies of steel stamping dies, exploring their design, manufacturing process, and significance in modern production.

What Are Steel Stamping Dies?

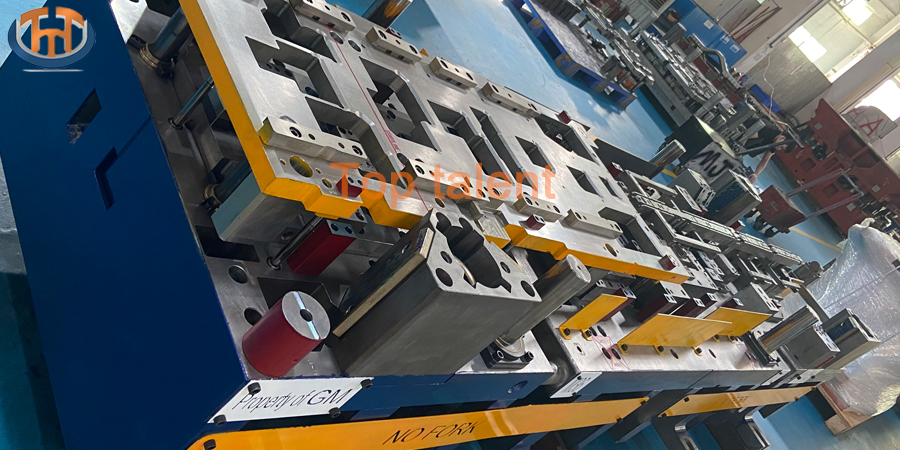

At its core, a steel stamping die is a tool used to cut or shape metal into specific forms. It comprises two primary components: the male and female sections, which come together to perform the stamping operation. When a steel sheet is placed between these sections, the die exerts tremendous pressure, shaping the metal according to the desired specifications. The versatility of these dies allows for the creation of intricate designs and high-volume production runs.

Design Considerations

The design of steel stamping dies is a meticulous process that requires a deep understanding of both the material properties and the intended application. Engineers must consider factors such as the type of steel being used, the thickness of the material, and the complexity of the part being produced. Advanced computer-aided design (CAD) software is often employed to simulate the stamping process, allowing for optimization before the physical die is fabricated.

Durability is another critical aspect of die design. Steel stamping dies are subjected to immense forces, which can lead to wear and tear over time. Selecting the right type of steel for die construction is vital; high-carbon and tool steels are commonly chosen for their hardness and resistance to deformation. Additionally, surface treatments such as nitriding can enhance the lifespan of the die by increasing its wear resistance.

Manufacturing Process

The manufacturing of steel stamping dies involves several key steps. Initially, detailed designs are created and verified using CAD tools. Once approved, the fabrication begins, often utilizing high-precision machining techniques such as CNC milling and electrical discharge machining (EDM). These methods allow for the intricate details required in the die to be achieved with a high degree of accuracy.

After the die components are machined, they are assembled and tested. This testing phase is critical, as it ensures that the die performs as intended under real-world conditions. Any adjustments are made at this stage to refine the performance and achieve optimal results during the stamping process.

The Role of Steel Stamping Dies in Modern Manufacturing

Steel stamping dies are indispensable in the production landscape. They contribute to the efficiency of manufacturing processes by enabling the mass production of components with high precision and repeatability. This consistency is especially important in industries such as automotive, where safety and performance depend on the reliability of each part.

Moreover, the use of stamping dies can lead to significant cost savings. By reducing material waste and minimizing labour requirements, manufacturers can achieve higher profit margins. The scalability of die production means that businesses can respond quickly to market demands, ramping up production without sacrificing quality.

Conclusion

In conclusion, steel stamping dies are fundamental tools that facilitate the transformation of raw materials into high-quality components across various industries. Their design and manufacturing are intricate processes that demand expertise and precision. As technology continues to advance, the evolution of steel stamping dies will likely lead to even more innovative solutions in manufacturing, driving efficiency and enhancing product quality in the years to come.

Post time: Nov-01-2024

.png)

.png)