TTM group was established in 2011, with a factory area of 16,000 square meters and a total of 320 employees.We are a professional Stamping tool manufacturer,a professional tooling fixture components/station/fixture&jigs manufacturer,a professional Checking fixture&gagues manufacturer One stop service.Here we want to share the features of exterior bumper parts.

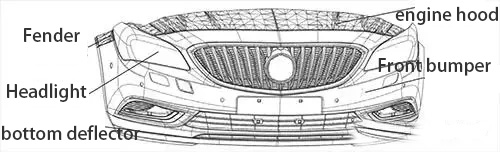

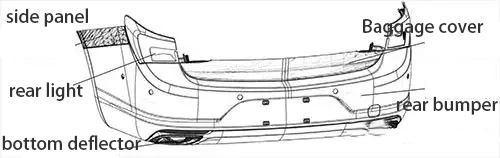

The car exterior parts take the front and rear bumper assembly as an example, the parts that match the front bumper include: hood, headlights, fenders, lower deflectors or plastic brackets to install the fins; parts that match the rear bumper There are: trunk lid, rear taillights, side wall outer panels, lower deflectors or plastic brackets to install the fins, as shown in Figure 1 and Figure 2.

Figure 1 Appearance components of automobile front bumper assembly

Figure 2 Appearance components of automobile rear bumper assembly

These relatively simple matching relationships are the entry point for the design of bumper assembly inspection tools, that is, the similarity of the matching area provides feasibility for the standardization of bumper inspection tool design; as the development of new models accelerates, the family face becomes the main engine factory The design is mainstream, especially the front and rear bumper assembly, which also lays a good foundation for the standardization of inspection tool design.

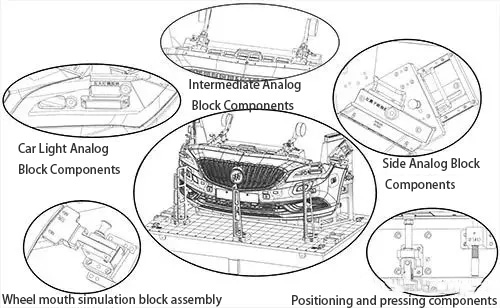

Front and rear bumper assembly inspection tool

According to the structural characteristics of the bumper, combined with the drawings and the requirements of the Body Design Tolerance Specification (DTS), the basic structure of the front and rear bumper assembly inspection tools (see Figure 3) is divided into five modules.

Figure 3 The five modules of the bumper assembly inspection tool

Front bumper inspection tool: hood simulation block, headlight simulation block, fender, positioning fastening, wheel opening simulation block; rear bumper inspection tool: trunk lid simulation block, rear tail light simulation block, side panel, Locate fastening, wheel mouth simulation blocks and standardize their modules.

The standardization of the intermediate analog block components is for the hood matching the front bumper or the trunk lid matching the rear bumper. The analog block adopts a flip structure design, and the hood is measured with a plastic feeler gauge through the analog block (SAICGM also has a measuring block that can be replaced). The gap between the front bumper or the trunk lid and the rear bumper is also convenient for data collection through the setting of the metering point (position according to the product measurement plan), and the calculation of whether it meets the size requirements.

Here is all we want to share,hope can help you all!

Post time: Apr-07-2023

.png)

.png)