In the world of metal fabrication and manufacturing, custom stamping dies play a pivotal role in ensuring accuracy, efficiency, and quality in producing complex parts and components. Stamping dies are specialized tools designed to cut or shape metal sheets, forming them into desired shapes or configurations through processes such as bending, cutting, or punching. While there are standard dies available for general applications, custom stamping dies are tailored to meet specific requirements, offering unique advantages for manufacturers with specialized needs.

What Are Custom Stamping Dies?

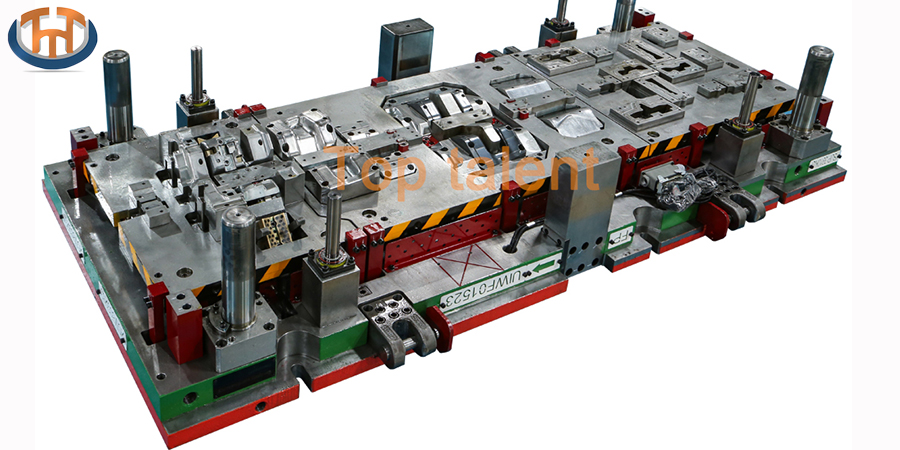

A stamping die is a precision tool that, when used in conjunction with a press, forms metal into a particular shape. Custom stamping dies differ from standard dies in that they are engineered to meet precise specifications, often for unique or complex components that cannot be easily produced using off-the-shelf dies. This customization allows manufacturers to optimize the design, functionality, and performance of the dies for their particular application, whether it involves intricate shapes, tight tolerances, or specialized materials.

Custom dies are usually made from high-quality steel, chosen for its durability and resistance to wear. These dies consist of two primary components: the male punch and the female die, which together create the force and shape needed to form or cut the material. The press drives the punch into the die, applying substantial force to shape the metal. The precision with which the dies are crafted ensures the final product matches the exact design specifications.

The Importance of Customization

For many industries, from automotive to aerospace, having the ability to produce highly specific components is crucial. Custom stamping dies allow manufacturers to meet these specific requirements without compromising on quality or efficiency. Customization provides the flexibility to design dies that can handle unique materials, thicknesses, and production volumes. It also ensures that parts can be produced consistently with minimal waste and high repeatability, a critical factor in high-volume production settings.

In industries where tight tolerances and complex geometries are required, custom stamping dies provide the solution. For example, in the automotive industry, intricate parts like transmission components or body panels must be produced with extreme precision to ensure they fit and function properly. Custom dies are designed to meet these stringent requirements, minimizing the margin of error and reducing the need for secondary processes such as trimming or additional machining.

The Design and Manufacturing Process

Creating a custom stamping die involves several stages, each requiring collaboration between designers and engineers. The process begins with a thorough analysis of the part that needs to be produced. This includes studying the material, the required dimensions, and the specific tolerances that need to be met. Once the design is finalized, computer-aided design (CAD) software is typically used to create a virtual model of the die.

After the design phase, the die is manufactured using precision machining processes, such as CNC milling or electrical discharge machining (EDM). These methods ensure that the dies are crafted with exceptional accuracy. Once produced, the die undergoes rigorous testing to ensure it can withstand the stresses of production and consistently produce parts to specification.

Benefits of Custom Stamping Dies

The key advantage of custom stamping dies is their ability to produce parts that meet exact specifications. This level of precision reduces errors, minimizes material waste, and leads to lower production costs over time. Additionally, custom dies are often more durable and longer-lasting than standard dies because they are engineered specifically for the materials and processes used in production.

For businesses with specialized production needs, investing in custom stamping dies offers long-term benefits, including improved product quality, faster production times, and reduced costs due to fewer reworks or adjustments. In a highly competitive manufacturing environment, this can provide a significant edge.

Conclusion

Custom stamping dies are indispensable tools for manufacturers seeking precision, efficiency, and flexibility in producing complex metal components. By tailoring the design of the dies to the specific needs of a project, manufacturers can achieve higher quality and efficiency, ensuring that their products meet the most demanding industry standards. Whether for high-volume production or specialized one-off parts, custom stamping dies remain a cornerstone of modern manufacturing.

Post time: Oct-10-2024

.png)

.png)