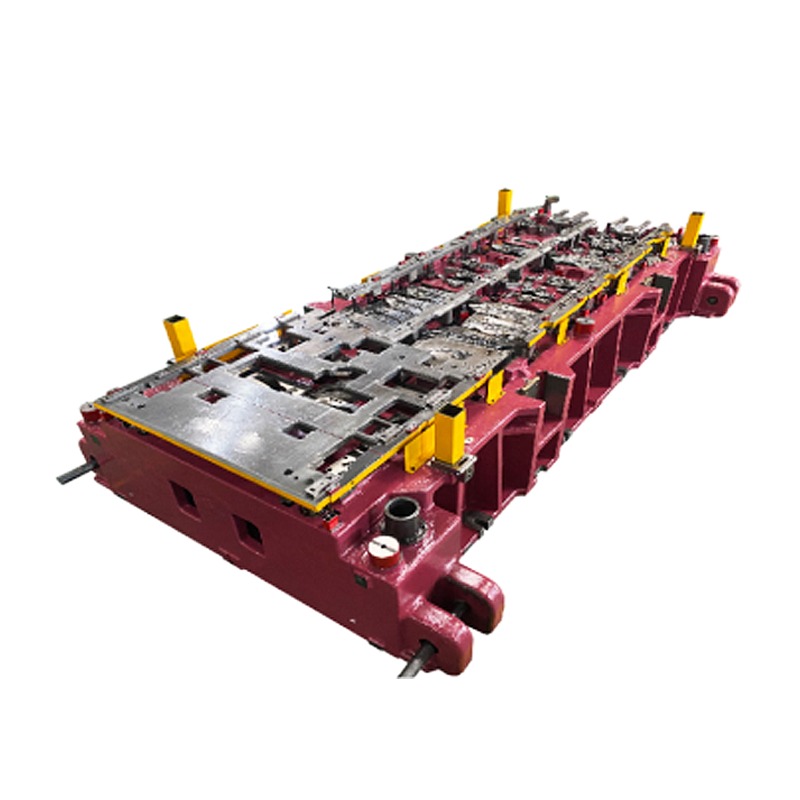

Massive Selection for Rail Welding Fixture - 0.15 Processing Precision Welding Jig , 1300 * 950 * 1150mm Welding Fixture – TTM

Massive Selection for Rail Welding Fixture - 0.15 Processing Precision Welding Jig , 1300 * 950 * 1150mm Welding Fixture – TTM Detail:

|

Base Supporter: |

Steel |

Body Material: |

Steel |

|

Holder Material: |

Al |

Base Color: |

Oxidation Original And Paint |

|

Weight: |

235KG |

Size: |

1300*950*1150mm |

Welding Fixtures And Jigs Of Automotive Part Special Customized

The positioning of these dial indicators must be built with a high level of precision so that the repeatability

of the measurement results is good enough. An approved method is to compare 2 bolts with 1 magnet.

All constructions for positioning the dial indicators must be built with low-wear-materials because of the high

level of usage. Polyurethane, brass and copper are not allowed to use as low-wear-materials.

Our production detail

| Items | ||

| 1 | Base Material | Al |

| 2 | Application | Stamping Parts |

| 3 | Surface treatment | Oxidation/Paint |

| 4 | Processing Precision | 0.15 |

| 5 | Accuracy for Other Profiles | 0.1 |

| 6 | Accuracy for Datum Hole | ±0.05 |

| 7 | Certificate | ISO 9001:2008 |

| 8 | CMM certification | Yes |

| 9 | Software | Catia, UG, CAD, STP |

| 10 | Specification | 1300*950*1150mm |

| 11 | Packing | Wooden Box |

Material

Base Plate: Aluminium

Main Base Frame:Steel

Components: Aluminium and Steel with heat treatment

Color

Base Plate Surface: Treated with rust-preventative oil.

Main Base Frame and Supports: Green Color

The Steel and Aluminum Parts: Black Anodized

Manufacturing tolerance

1.The Location Datum ±0.05mm

2.The Surface ±0.15mm

3.The Checking Pins and Holes ±0.1mm

Process

CNC Machining(Milling/Turning), Grinding

Black Anodized Treatment

Design Hours(h): 60h

Quality Control

CMM (3D Coordinate Measuring Machine), HR-150 A Hardness Tester

Lead time & Packing

2 months after 3D design approved

15 days via sea: HMM

Standard Export Wooden Case

Quality Policy

Legal Compliance

Customer First

Total Quality Control

System Operation

Continuous Improvement

More

We’re dedicated to providing our customers with high quality, practical, and cost-effective solutions that serve a variety of needs in the areas of checking fixtures, welding fixtures and jigs! We will work closely with customers to define their needs and assess critical design factors such as functionality, productivity requirements.

Product detail pictures:

Related Product Guide:

To be a result of ours specialty and repair consciousness, our corporation has won an excellent reputation amongst customers all around the entire world for Massive Selection for Rail Welding Fixture - 0.15 Processing Precision Welding Jig , 1300 * 950 * 1150mm Welding Fixture – TTM , The product will supply to all over the world, such as: Seattle, Chicago, European, We hope we can establish long-term cooperation with all of the customers, and hope we can improve competitiveness and achieve the win-win situation together with the customers. We sincerely welcome the customers from all over the world to contact us for anything you need!Welcome all customers both at home and abroad to visit our factory. We hope to have win-win business relationships with you, and create a better tomorrow.

The supplier abide the theory of "quality the basic, trust the first and management the advanced" so that they can ensure a reliable product quality and stable customers.

.png)

.png)