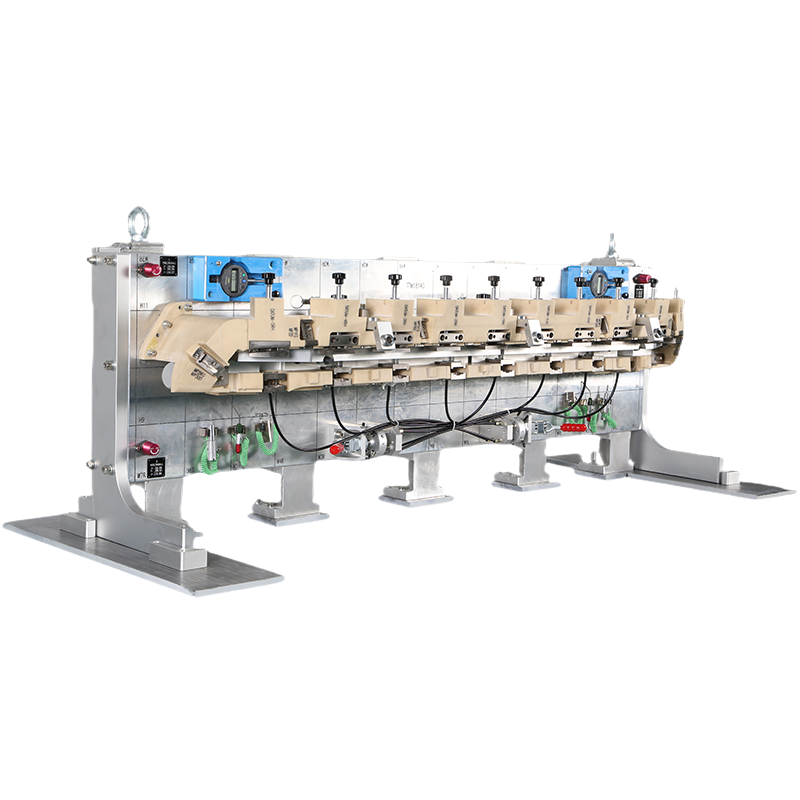

Manufactur standard Seat Assembly Checking Fixtures - Special customized inspection Hot Forming Part Checking fixture – TTM

Manufactur standard Seat Assembly Checking Fixtures - Special customized inspection Hot Forming Part Checking fixture – TTM Detail:

Function

In the link of mass production, in the face of harsh customers, especially aviation and automobile, medical industry requirements before, even under the requirements of 100% full inspection, completely rely on the operator to maintain a clear brain and have skilled skill level, this is an incredible thing. So there are always parts that can’t be controlled in place, or even installed on the assembly properly. This can lead to several things. First, the consumption of parts in the production process. Second, the part enters the assembly or assembly link, causing the abnormality of the component or the whole part. In the third and worst case, the component is ignored and reaches the customer. Once the finished product is in the hands of consumers, these components can quickly break down, causing greater losses and customer complaints.

Application Fields

Automotive industry quality control.

Automotive production line production capacity improve.

Specification

|

Fixture Type: |

Hot Forming Part Checking fixture |

|

Size: |

1910*1200*780 mm |

|

Weight: |

320 KG |

|

Material: |

Main Construction: metal Support: metal |

|

Surface treatment: |

Base Plate: Electroplating Chromium and Black Anodized |

Detailed Introduction

In dealing with complex and multi-size, such as shaft, the shape of multi-size step shaft is more complex, such as groove, outer diameter, total length, inverted circle, groove, etc., the traditional detection tool method takes a long time to measure, and cannot detect a large number of parts, and the various sizes increase the difficulty and error of detection. In order to meet customer needs, we can customize multi-interval function and select gradient detection and verification equipment for customers. The feedback image shows OK and NG in bright green and red, which is clear at a glance and greatly improves work efficiency.

Our company undertakes all kinds of non-standard automatic testing equipment, quality checking fixtrue, can be designed according to the needs, to achieve economic and practical.

Lead Time & Packing

30 days after 3D design approved

5 days via express: FedEx by Air

Standard Export Wooden Case

Product detail pictures:

Related Product Guide:

With our leading technology at the same time as our spirit of innovation,mutual cooperation, benefits and advancement, we will build a prosperous future with each other with your esteemed firm for Manufactur standard Seat Assembly Checking Fixtures - Special customized inspection Hot Forming Part Checking fixture – TTM , The product will supply to all over the world, such as: Mexico, Jakarta, India, If any product meed your demand, remember to feel free to contact us. We're sure your any inquiry or requirement will get prompt attention, high-quality merchandise, preferential prices and cheap freight. Sincerely welcome friends all over the world to call or come to visit, to discuss cooperation for a better future!

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!

.png)

.png)