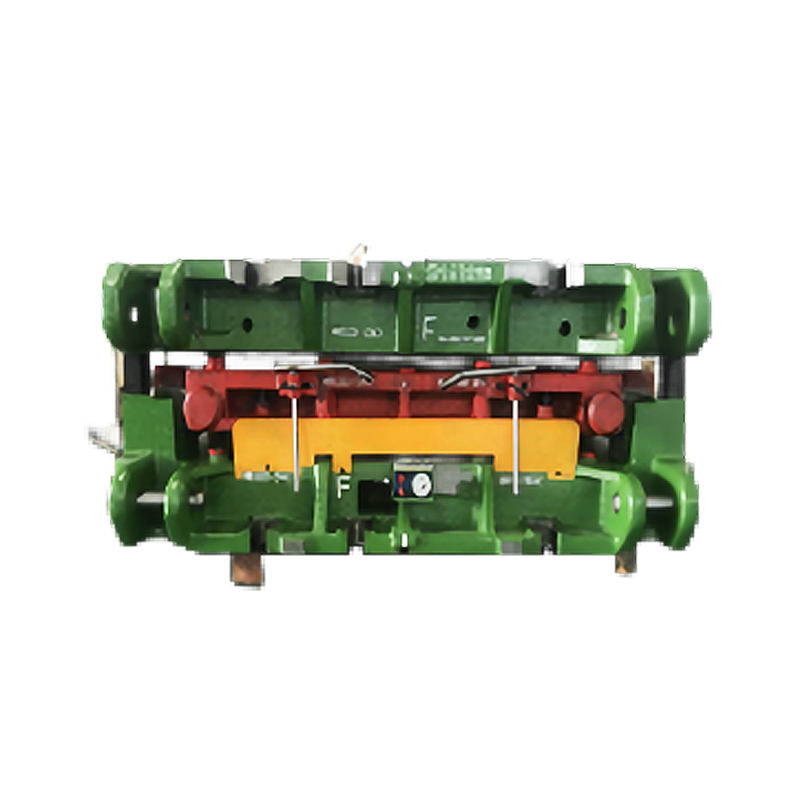

Hot sale Maching Parts Cnc - High Quality Supporting Various Specifications Fixture Machine Pressing Lines,Welding Lines and Assembly Lines Robotic Units Robotic Racks – TTM

Hot sale Maching Parts Cnc - High Quality Supporting Various Specifications Fixture Machine Pressing Lines,Welding Lines and Assembly Lines Robotic Units Robotic Racks – TTM Detail:

Application Fields

Automotive industry quality control

Automotive production line production capacity improve

Specification

|

Fixture Type: |

Custom Special Purpose Tooling |

|

Size: |

1800x1300x900mm |

|

Weight: |

35KG |

Product Details

Design Principles

Because the design of Robotic Racks is a more flexible and changeable technical work with many related factors, we can only abstract out the common factors and get some general design principles.

(1) Before design, the operation object must be fully analyzed and the most reasonable operation process must be drawn up;

(2) It must meet the functional requirements and environmental conditions of the operation;

(3) Must meet the production schedule requirements;

(4) The whole and each component must all meet the safety norms and standards;

(5) Each equipment and control system shall be equipped with fault display and alarm devices;

(6) Easy to maintain and repair;

(7) The operating system is convenient for networked control;

(8) The workstation is convenient for line grouping;

(9) The operating system should be simple and clear, easy to operate and manual intervention;

(10) Economic benefits, rapid production.

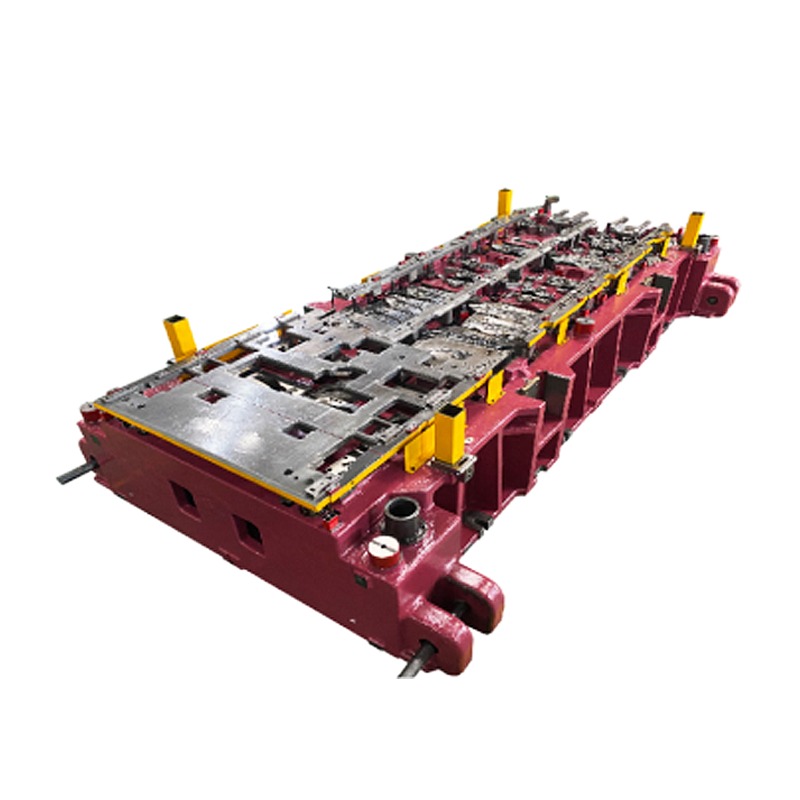

Basic Requirements

(1) Accurate and reliable positioning and clamping can reduce or even cancel the cutting and marking work. Reduce the products

The size deviation improves the precision and changeability of the parts.

(2) Effectively prevent and reduce the deformation of the amendment.

(3) The workpiece is in the best welding site, the weld formality is good, the process defects are significantly reduced, welding

The connection speed can be increased.

(4) Mechanical devices instead of manual assembly parts of the positioning, clamping and workpiece turnover and other heavy

Work has improved the working conditions of workers.

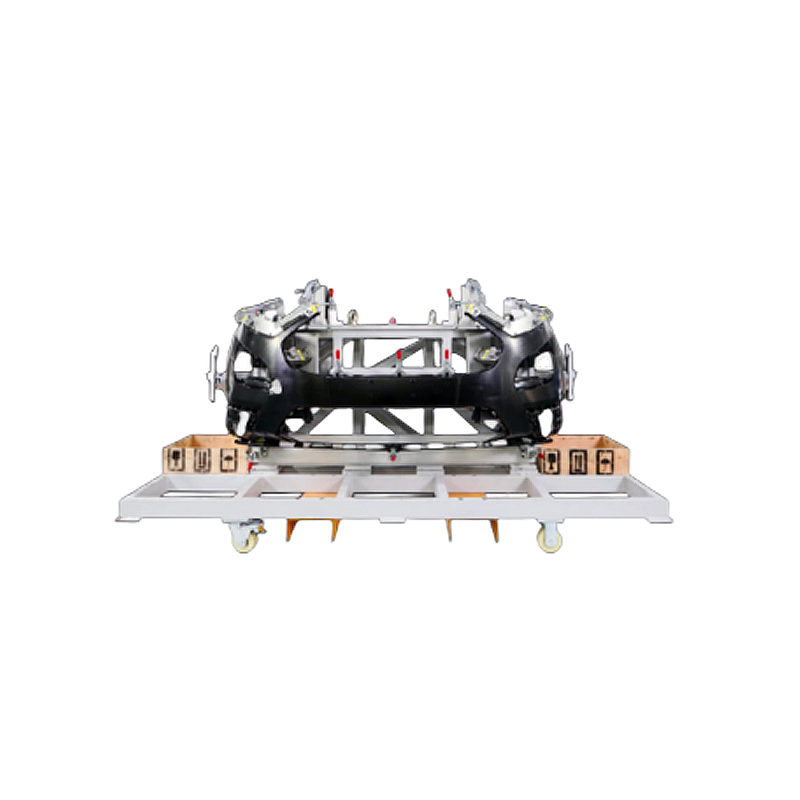

Advantages

1, the clamping effect is accurate, in the clamping state should be able to maintain self-locking, to ensure the safety and reliability of clamping positioning;

2. Quick clamping action, convenient operation and labor saving, clamping should not damage the surface quality of parts;

3, clamping parts should have a certain rigidity and strength, clamping force should be adjustable;

4, the structure is simple, easy to manufacture and maintenance.

Lead time & Packing

30 days after 3D design approved

5 days via express: FedEx by Air

Standard Export Wooden Case

Product detail pictures:

Related Product Guide:

Our organization sticks to your principle of "Quality may be the life of your organization, and reputation will be the soul of it" for Hot sale Maching Parts Cnc - High Quality Supporting Various Specifications Fixture Machine Pressing Lines,Welding Lines and Assembly Lines Robotic Units Robotic Racks – TTM , The product will supply to all over the world, such as: New Delhi, Pretoria, Washington, We adhere to the honest, efficient, practical win-win running mission and people-oriented business philosophy. Excellent quality, reasonable price and customer satisfaction are always pursued! If you are interested in our items, just try to contact us for more details!

Wide range, good quality, reasonable prices and good service, advanced equipment, excellent talents and continuously strengthened technology forces,a nice business partner.

.png)

.png)