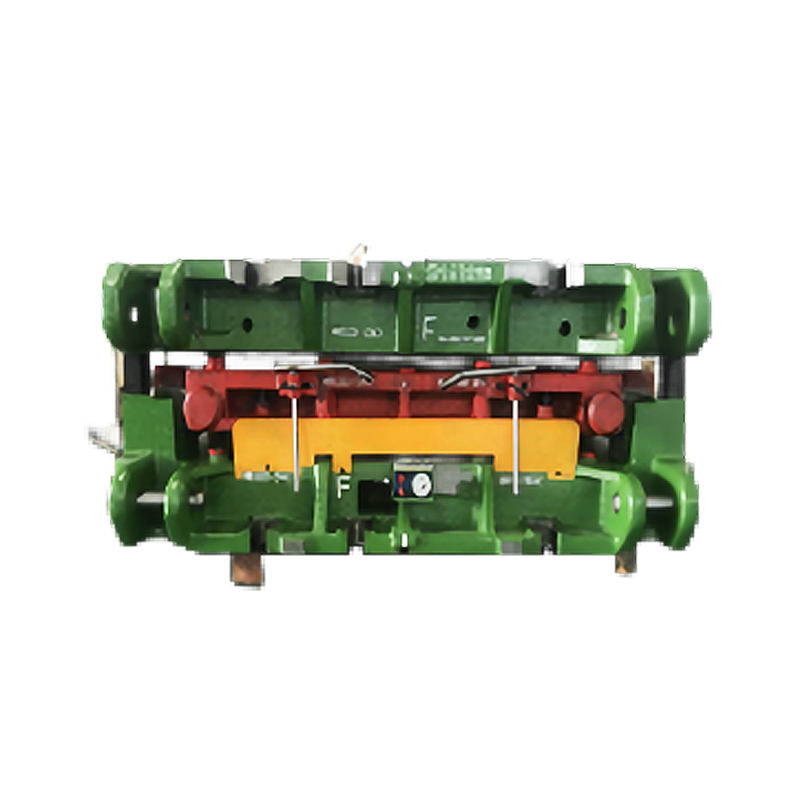

Hot Sale for Variable Gauges And Fixtures - Gom fixture For Fender ,Casting Aluminium Parts Checking Fixtures – TTM

Hot Sale for Variable Gauges And Fixtures - Gom fixture For Fender ,Casting Aluminium Parts Checking Fixtures – TTM Detail:

Specification

|

Fixture Type: |

Assembly Carbon Fibre Part Checking Fixtures |

|

Size: |

1600*1100*1000 |

|

Weight: |

95KG |

Detailed Introduction

The utility model discloses a physical examination tool for automobile front fender, which relates to the technical field of automobile front fender body detection. In order to solve the problem that the physical examination tool for automobile front fender on the market can only detect the front fender of a specific vehicle, and the limitation is too obvious, which is not conducive to large-scale promotion. Stated at the bottom of the setting of the top of the frame has a mounting plate, referred to the top of the mounting plate set a regulating block, described in the positioning block and the adjustment holes through the positioning bolt connection mutually, described in regulating side fixed link at the top of the block is installed, described in the regulating block the other side of the upper end fixed connected with one end of the spring, as described in the top set has a rotating rod end of the installation seat, The other end of the rotating rod is fixedly connected with one end of the splint, the other end of the splint is fixedly connected with the other end of the spring, the inner part of the splint is arranged between the rotating rod and the spring is provided with a positioning pin, and the inner part of the placement box is provided with a feeler.

The Working Flow

1. Received the purchasing order -——-> 2. Design -——-> 3. Confirming the drawing/solutions -——-> 4. Prepare the materials -——-> 5. CNC -——-> 6. CMM -——-> 6. Assembling -——-> 7. CMM-> 8. Inspection -——-> 9. (3rd part inspection if need) -——-> 10. (internal/customer on site) -——-> 11. Packing(wooden box) -——-> 12. Delivery

Manufacturing Tolerance

1. The Flatness of Base Plate 0.05/1000

2. The Thickness of Base Plate ±0.05mm

3. The Location Datum ±0.02mm

4. The Surface ±0.1mm

5. The Checking Pins and Holes ±0.05mm

Product detail pictures:

Related Product Guide:

Adhering into the basic principle of "quality, assistance, effectiveness and growth", we have attained trusts and praises from domestic and worldwide client for Hot Sale for Variable Gauges And Fixtures - Gom fixture For Fender ,Casting Aluminium Parts Checking Fixtures – TTM , The product will supply to all over the world, such as: Netherlands, France, Malaysia, Abiding by our motto of "Hold well the quality and services, Customers Satisfaction", So we provide our clients with high quality products and excellent service. Please feel free to contact us for further information.

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.

1.png)

.png)

.png)