Hot Sale for Variable Gauges And Fixtures - Assembly Checking Fixture for Metal Stamping Parts – TTM

Hot Sale for Variable Gauges And Fixtures - Assembly Checking Fixture for Metal Stamping Parts – TTM Detail:

Function

Old version single checking fixture, it is a set of inspection tools can only be applied to a single model, detection function. A deficiency, such as a deficiency; And the degree of automation is low. The production of different models need different inspection tools, and each set of inspection tools occupies a large space area, which brings inconvenient user management and high production cost. The technical problem to be solved by the utility model is to provide an assembly checking fixture.

Application field

Automotive industry quality control.

Automotive production line production capacity improve.

Product Details

Specification

|

Fixture Type: |

Assembly CF for Metal Stamping Part |

|

Size: |

4650x850x3400 |

|

Weight: |

3550 KG |

|

Material: |

Main Construction: metal Support: metal |

Detailed Introduction

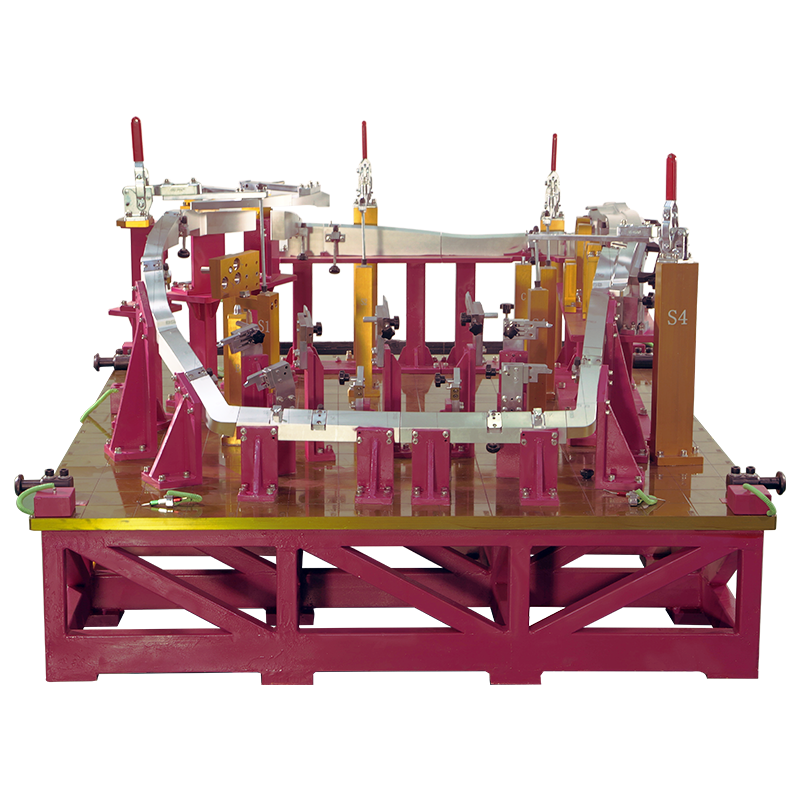

This is the vehicle function parts assembly check fixture model. The product is a large injection molded part. After the assembly of various parts and circuit boards is completed, it is put into the inspection tool for batch inspection. It is the last process before production and packaging after functional testing. Inspection tools include: 0 position plane, 3mm gap detection position, difference gauge, gap detection gauge, reference block, body coordinate system, etc

Engineering & Design

Research and Development

Design Concept&Proposal

In-house design & detail services

3D parametric solid modeling

2D Drawing Building

FEA analysis available

On-line web conference design review

Engineering Change Technical Support

Design Software: UG(Unigraphics NX)

Catia and Autodesk-Auto-CAD

Our deign team will take project responsibility system to manage all of the projects from our customers.

Project leaders with at least 10 years experience in this industry will take care of every project.

Project leader: 12 years experience, 5 people

Designer: 5 to 8 years experience, 12 people; 3 to 5 years experience, 7 people; 1 to 2 years experience, 6 people

The Working Flow

1. Received the purchasing order -——-> 2. Design -——-> 3. Confirming the drawing/solutions -——-> 4. Prepare the materials -——-> 5. CNC -——-> 6. CMM -——-> 6. Assembling -——-> 7. CMM-> 8. Inspection -——-> 9. (3rd part inspection if need) -——-> 10. (internal/customer on site) -——-> 11. Packing(wooden box) -——-> 12. Delivery

Lead time & Packing

45 days after 3D design approved

5 days via express: FedEx by Air

Standard Export Wooden Case

Product detail pictures:

Related Product Guide:

All we do is usually affiliated with our tenet " Buyer to start with, Belief to start with, devoting about the food packaging and environmental defense for Hot Sale for Variable Gauges And Fixtures - Assembly Checking Fixture for Metal Stamping Parts – TTM , The product will supply to all over the world, such as: Portugal, Montreal, Croatia, We put the product quality and customer's benefits to the first place. Our experienced salesmen supply prompt and efficient service. Quality control group make sure the best quality. We believe quality comes from detail. If you have demand, allow us to work together to get success.

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.

.png)

.png)