Hot Sale for Die Metal Stamping - Custom Precision Manufacturing Parts High Pressure Metal Press Molds Casting and steel Transfer Die – TTM

Hot Sale for Die Metal Stamping - Custom Precision Manufacturing Parts High Pressure Metal Press Molds Casting and steel Transfer Die – TTM Detail:

Function

The transfer die can be transmitted by the manipulator, which greatly improves the production efficiency, reduces the production and manufacturing cost, and saves the material cost. The transfer die combines the advantages of single process die and progressive die, and has the characteristics of quality safety, stability and reliability.

Characteristic

Transfer die can improve the method of low casting efficiency, the specific steps are ![]() 1) when the first mold is filled with low pressure casting, transfer the filled first mold, bring the second mold not filled to the filling position, the second mold filling; (2) In the process of filling the mold that is not filled, open and close the mold that is filled and solidified, and repeat steps (1) and (2). The invention can effectively improve the production efficiency of low-pressure casting, transfer the process of casting condensation and mold opening and closing, realize the time optimization of production technology, and further promote the application scope of low-pressure casting.

1) when the first mold is filled with low pressure casting, transfer the filled first mold, bring the second mold not filled to the filling position, the second mold filling; (2) In the process of filling the mold that is not filled, open and close the mold that is filled and solidified, and repeat steps (1) and (2). The invention can effectively improve the production efficiency of low-pressure casting, transfer the process of casting condensation and mold opening and closing, realize the time optimization of production technology, and further promote the application scope of low-pressure casting.

Product Details

Detailed Introduction

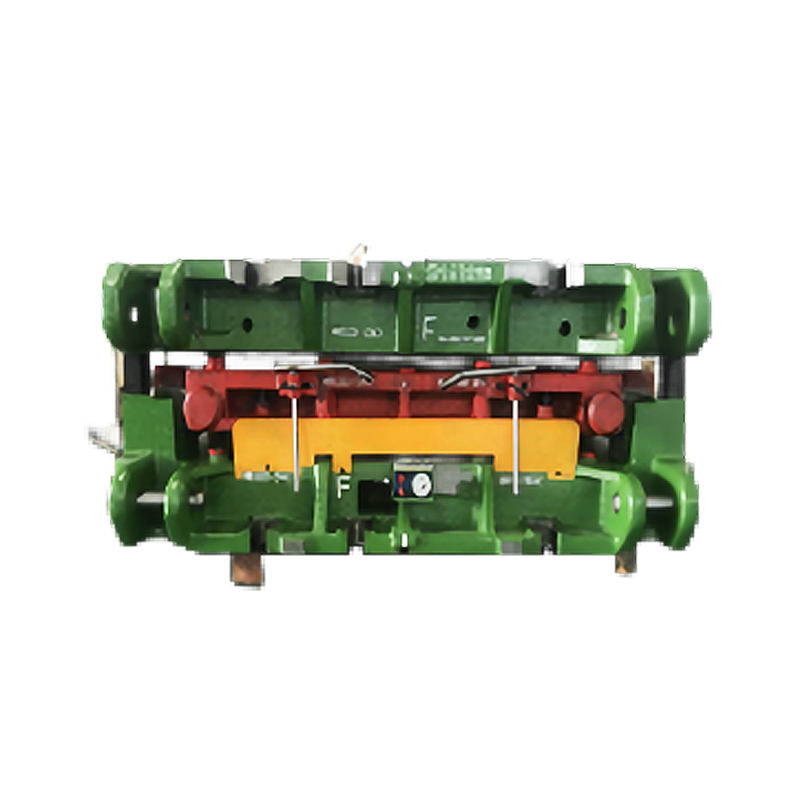

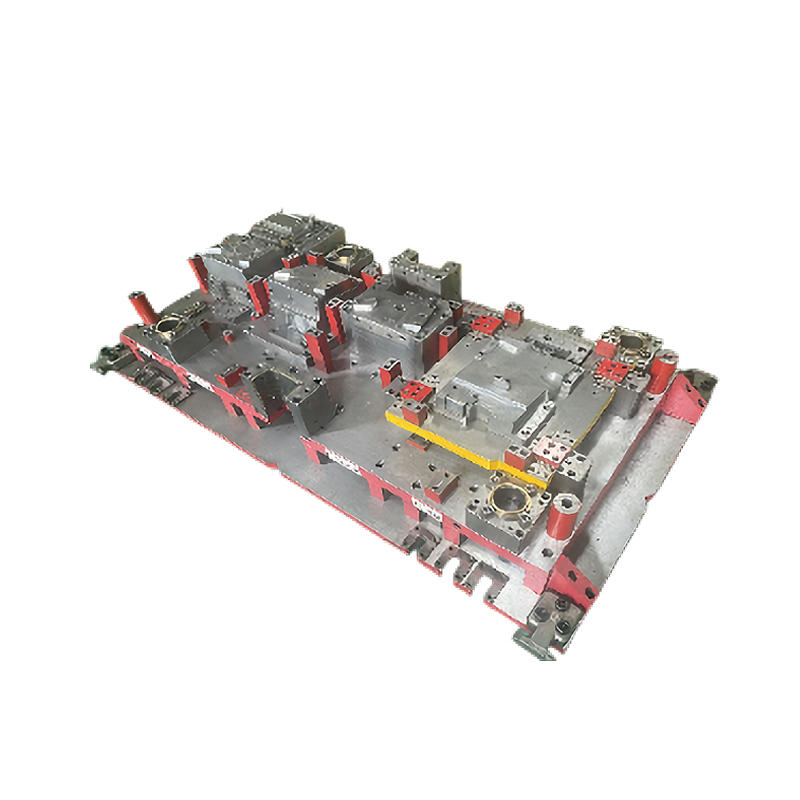

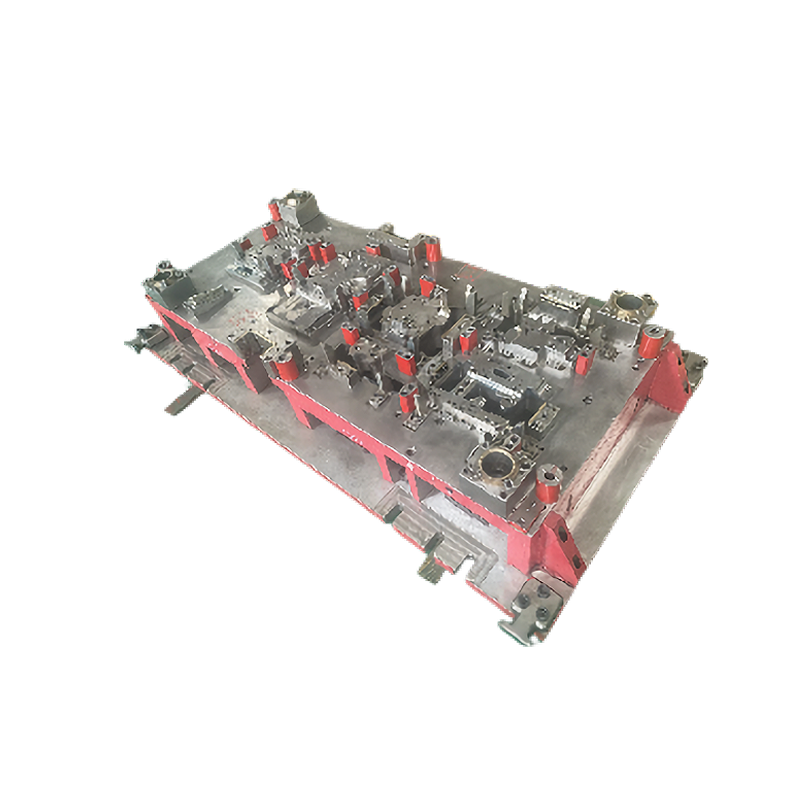

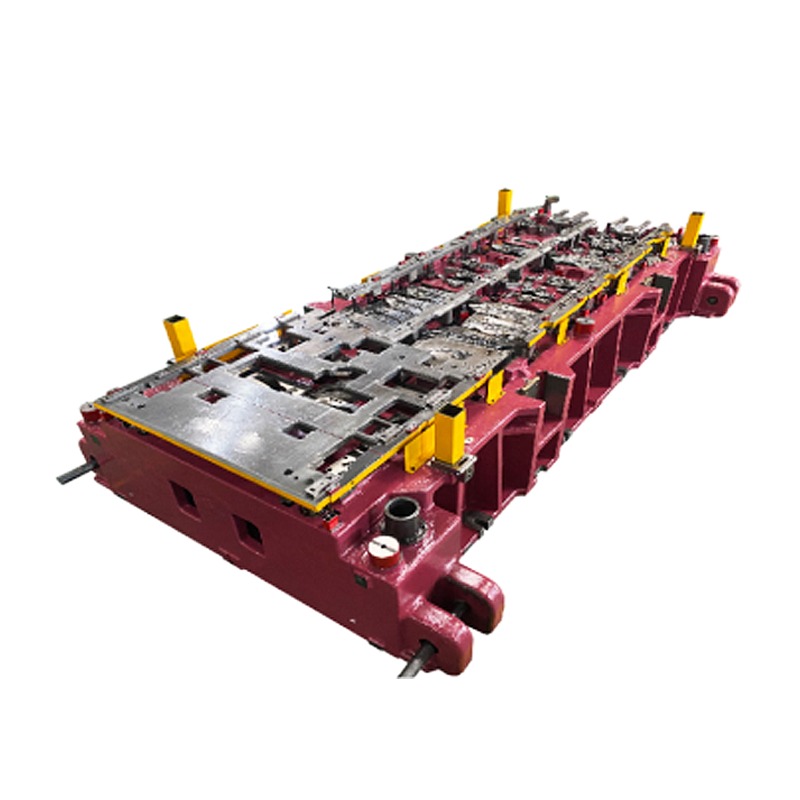

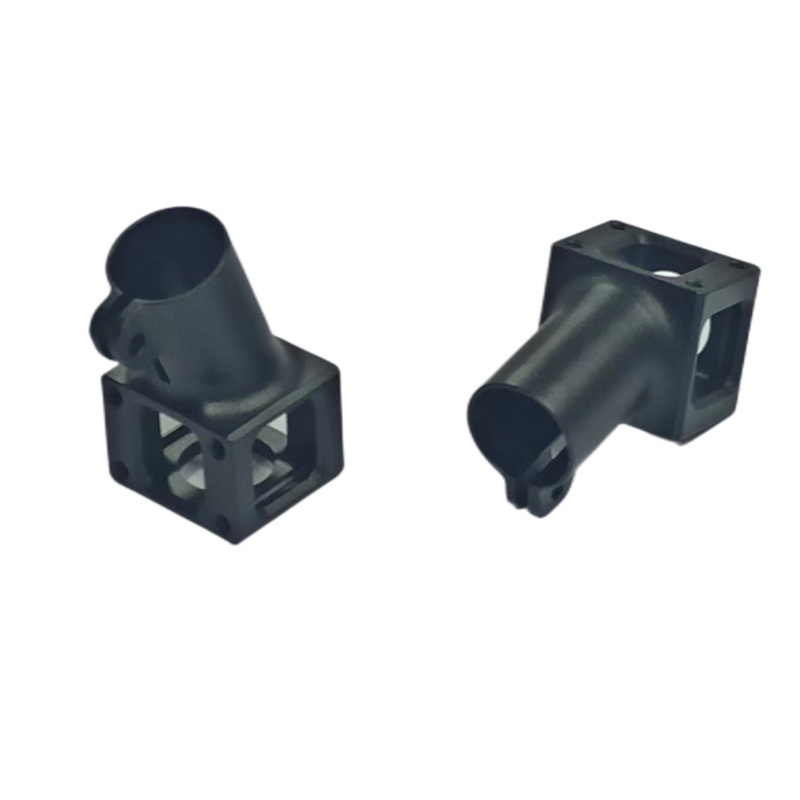

This is a Casting Transfer Die, totally in 5 sets, we made for our Canada customer. The piecework movement of multi-station press is realized by the three-dimensional movement of the small shovel or clamp fixed on the feed rod (beam). When designing the mold and gripper, it is necessary to check whether there is interference in the mold and gripper (clip) and the parts in advance.

The reference point of inspection should be selected at the point with the worst interference condition of the mold. The reference point of the front view is the uppermost front end of the gripper, as shown in the figure above. Special attention should be paid to whether there is interference when there is a hanging rod at the mark.

If the area a≥40mm, do not arrange parts that are too high to avoid interference.This figure mainly shows the process of the small shovel entering the mold for clamping parts and sending them to the lower sequence mold. The design should ensure that there is no interference in the left and right areas and the bottom area A ≥40mm during the entry process of the small shovel, and there is no interference in the process of lifting 200 and sending it to the lower sequence.

The movable object as follows: die wedge slider, supporting core, blank holder, top piece, etc., must be checked for interference in the state to be moved Whether the clearance with the lower die parts (guide column, positioning plate, buffer device, wedge slider, wedge drive block, wedge travel backplane, top piece, etc.) is A ≥40mm if the clearance is met, there will be no interference.

The check point is the most front and the lowest part of the gripper, and the space is ≥40mm. The parts are to be clamped. In the process of clamping and lifting outward, attention should be paid to the interference under the gripper, the gripper support rod and the parts.

The Working Flow

1. Received the purchasing order -——-> 2. Design -——-> 3. Confirming the drawing/solutions -——-> 4. Prepare the materials -——-> 5. CNC -——-> 6. CMM -——-> 6. Assembling -——-> 7. CMM-> 8. Inspection -——-> 9. (3rd part inspection if need) -——-> 10. (internal/customer on site) -——-> 11. Packing(wooden box) -——-> 12. Delivery

Lead time & Packing

45 days after 3D design approved

5 days via express: FedEx by Air

Standard Export Wooden Case

Product detail pictures:

Related Product Guide:

The pretty loaded projects management experiences and one to a person support model make the high importance of business enterprise communication and our easy understanding of your expectations for Hot Sale for Die Metal Stamping - Custom Precision Manufacturing Parts High Pressure Metal Press Molds Casting and steel Transfer Die – TTM , The product will supply to all over the world, such as: Kyrgyzstan, Adelaide, Oslo, Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation and sincerely welcome you to join us. In a word, when you choose us, you choose a perfect life. Welcome to visit our factory and welcome your order! For further inquiries, please do not hesitate to contact us.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.

1.png)

.png)

.png)