High-quality Automotive Casting progressive die manufacturer and Factory

Company Development

- In 2011, TTM was founded in ShenZhen.

- In 2012, Moving to DongGuan; Building cooperation relationship with Magna International Inc.

- In 2013 Introducing more advanced equipments.

- In 2016, Introduced large-scale CMM equipment and 5 axis CNC equipment; Cooperated with OEM Ford Completed Porsche, Lamborghini and Tesla CF projects.

- In 2017, Moving to current plant location; CNC was increased from 8 to 17 sets. Top Talent Automotive Fixtures & Jigs Co.Ltd was established

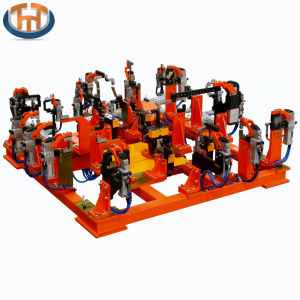

- In 2018, Cooperated with LEVDEO automotive and completed the automotion production line. 4-axis high-speed CNC was introduced, the total Qty of CNC reached 21.

- In 2019, Dongguan Hong Xing Tool & Die Manufacturer Co.,Ltd was established. (One stop service) Cooperated with Tesla Shanghai and Sodecia Germany. Built a new R&D laboratory for automation.

- In 2020, Cooperated with OEM ISUZU in SA ;Completed the RG06 One-Stop Service.

- In 2021, Moving forward with the quality belief to create a world-class enterprise.

- In 2022, TTM Group office was founded in Dongguan City, New CNC 4 axis*5 sets, New Press*630 tons, Hexagon Absolute Arm.

- In 2023, TTM is building a new plant for checking fixture and welding fixture business; adding one 2000T press.

Checking Fixture & Welding Jigs Factory (Total area: 9000m² )

Stamping Tools & Dies and Machined Parts Factory (Total area: 16000m²)

Overview

Essential details

Place of Origin: Guangdong, China Brand Name: TTM

Model Number. Stamping tool Shaping Mode: Die Casting

Product Material: Steel Product: Vehicle Mould

Product Name: Stamping tooling Material: Steel/casting/

Size: Customization or base on design standard components: Standard Lifter/can be customized

Usage: Automotive Die Set: Steel/Casting

Mould Life: 5-10 Years Mould base: Progressive/Transfer/Tandem

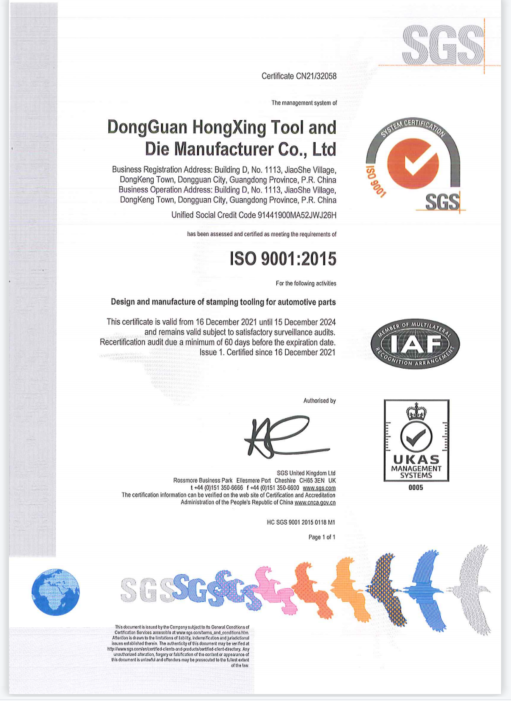

Certification: IS09001/TUV Weight: base on design

Products Description

| Brand Name | OEM |

| Product Name | Metal Stamping Die Or Stamping tool |

| Tolerance | Mating trim & form +/- 0.8mm, hole 0.6mm, genera trim & form +/- 1.5mm. |

| Material | SKD11, SKD61, Cr12MOV, D2, SKH9, RM56, ASP23 etc. |

| Design Software | Catia, UG, Autoform |

| Standard | IS09001 |

| Die Type | Compound Die, Transfer Die, Progressive die, Gang die or Tandem Die according to the customer's requirements |

| First Trial | 8-12 weeks after design approved |

| Die Life | Depends on customer’s production capacity |

| Quality confirm | CMM/Blue light scan report, also welcome customer to buy off on-site as per standard |

| Package | Plastic or wooden box for samples, wooden plate for stamping die or as per customer's requirements |

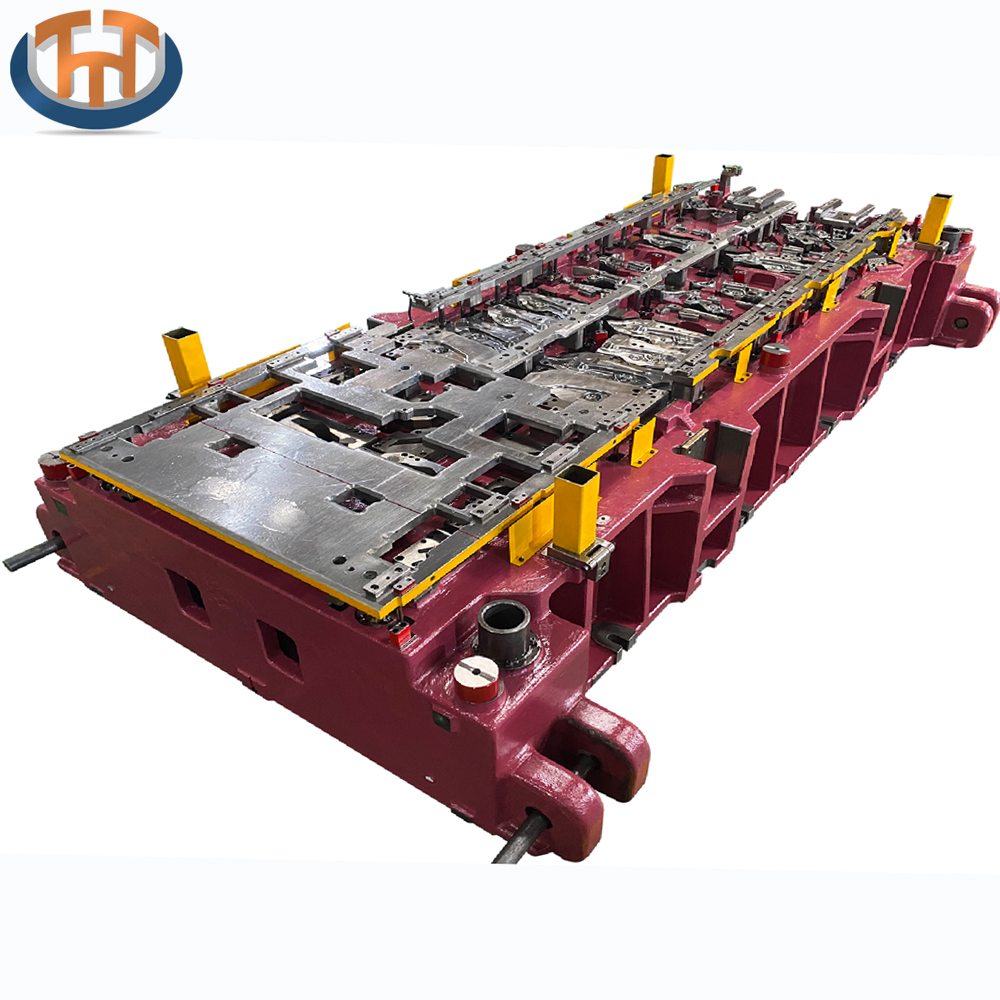

Automotive casting progressive die is a special tool used in the manufacturing process of automotive castings. It is designed for progressive die-casting machines, which can continuously produce automotive castings with high precision and high efficiency. A progressive die consists of multiple stations, each of which performs a specific operation. These stations consist of casting cavities into which molten metal or alloy is injected under high pressure to form the desired shape of the automotive casting. Other stations may include trimming, shaving, deburring and other finishing operations. A progressive die is designed to move the casting through these stations in an incremental fashion, each station performing a specific operation on the casting. This sequential movement allows for a continuous production process, with each station stepping through specific tasks until the final automotive casting is produced. By using progressive dies, automakers can achieve higher yields, improve part quality and reduce production costs compared to traditional casting methods. Progressive dies allow tighter control over casting dimensions, improve part consistency, and reduce material waste. Overall, automotive casting progressive dies are key tools in the automotive casting manufacturing process, enabling high-volume, high-quality production in an efficient and economical manner.

ISO Management System For Stamping Progressive Die

Our Automotive Progressive Die Team

We have more than 352 employees, 80% of which are senior technical engineers. Tooling division: 130 employees, Welding jig division:60 employees, Checking fixture division:162 employees, We have a professional sales & project management team, long-term service overseas projects, from RFQ to production, shipment, after-sales, our team can handle all problems for our customers in Chinese, English and German Language.

Our Advantages

1.Rich experience in automatic manufacturing and enterprise management.

2.One Stop Service for stamping tool, checking fixture, welding fixtures and cells to achieve timing and cost saving, communication convenience, to maximize customer profits.

3.Professional engineering team to finalize the GD&T between single part and assembly component.

4.Turnkey Solution Service-Stamping Tool, Checking Fixture, Welding Fixtures and Cells with one team.

5.Strong capability with international technical support and partnership cooperation.

6.Big capacity: Checking Fixture, 1500 sets/year;Welding Fixture/Cells, 400-600 sets/year; Stamping Tools, 200-300 sets/year.

Major Projects Experience Of Stamping Dies And Stamping Tools

| Item | Year | Project | Tool Q'ty | District |

| 1 | 2021 | GM-A100 | 10 | Mexico |

| 2 | 2021 | C234 | 4 | Mexico |

| 3 | 2021 | Cover carry / Battery Bracket | 18 | South Africa |

| 4 | 2021 | Q20-066 | 12 | USA / Canada |

| 5 | 2021 | VW/AUDI | 10 | Mexico |

| 6 | 2021 | TESLA | 5 | Mexico |

| 7 | 2022 | TESLA MODEL Y | 12 | USA / Mexico |

| 8 | 2022 | Audi Q5 | 9 | Mexico |

| 9 | 2022 | GM C223-L232 | 16 | Mexico |

| 10 | 2022 | DAIMLER_MMA P04562 | 6 | Germany |

| 11 | 2022 | Ford P703 Refurbish tool | 18 | South Africa |

| 12 | 2022 | FMCSA P703M | 7 | South Africa |

| 13 | 2022 | Tooling ISRI | 6 | Brazil |

| 14 | 2022 | JETTA PA2 PROYECT | 6 | USA / Mexico |

| 15 | 2022 | Audi 192C | 8 | USA / Mexico |

| 16 | 2022 | BMW | 5 | Czech Republic |

| 17 | 2022 | VW TYRON | 6 | Mexico |

| 18 | 2022 | Daimler AG | 6 | Germany |

Progressive Die Manufacturing Center

We can build all kinds of different size stamping tools including large size as we have big CNC Machines. With a variety of mechanical equipment such as milling, grinding, wire cutting machines and drilling machines, we can effectively and accurately control the processing process.

25 sets of CNC with 2 shift running

1 Set of 3-Axis CNC 3000*2000*1500

1 Set of 3-Axis CNC 3000*2300*900

1 Set of 3-Axis CNC 4000*2400*900

1 Set of 3-Axis CNC 4000*2400*1000

1 Set of 3-Axis CNC 6000*3000*1200

4 Set of 3-Axis CNC 800*500*530

9 Set of 3-Axis CNC 900*600*600

5 Set of 3-Axis CNC 1100*800*500

1 Set of 3-Axis CNC 1300*700*650

1 Set of 3-Axis CNC 2500*1100*800

5 Axis CNC -Machine

4 Axis CNC -Machine

Progressive Die Assembly Center

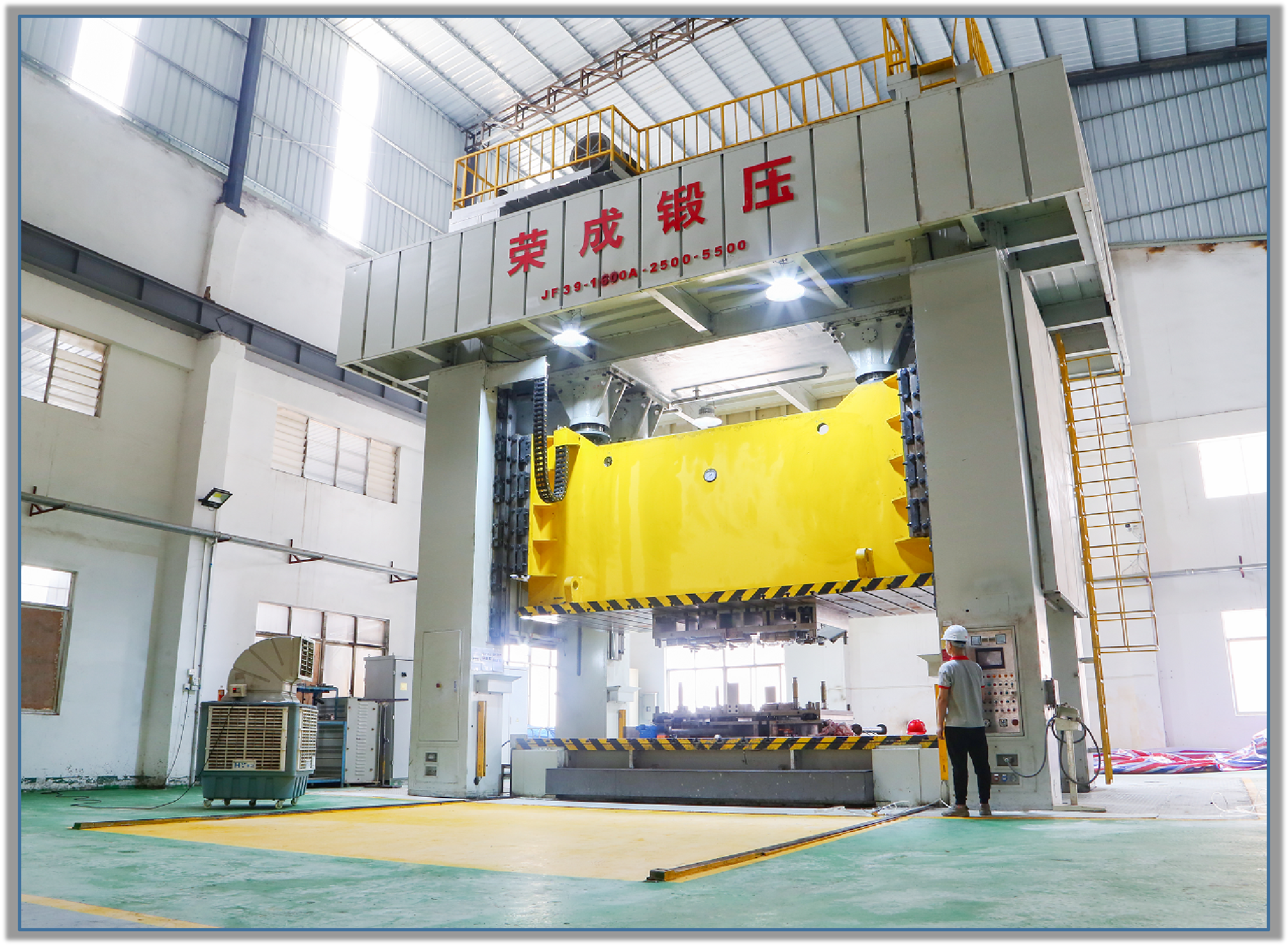

Progressive Die Press Center

Tonnage 630T: Bolster size :4000*2000 with coil feeder

Tonnage:800T: Bolster size :4000*2000 with coil feeder

Tonnage 1250T: Bolster size :5500*2500 with coil feeder

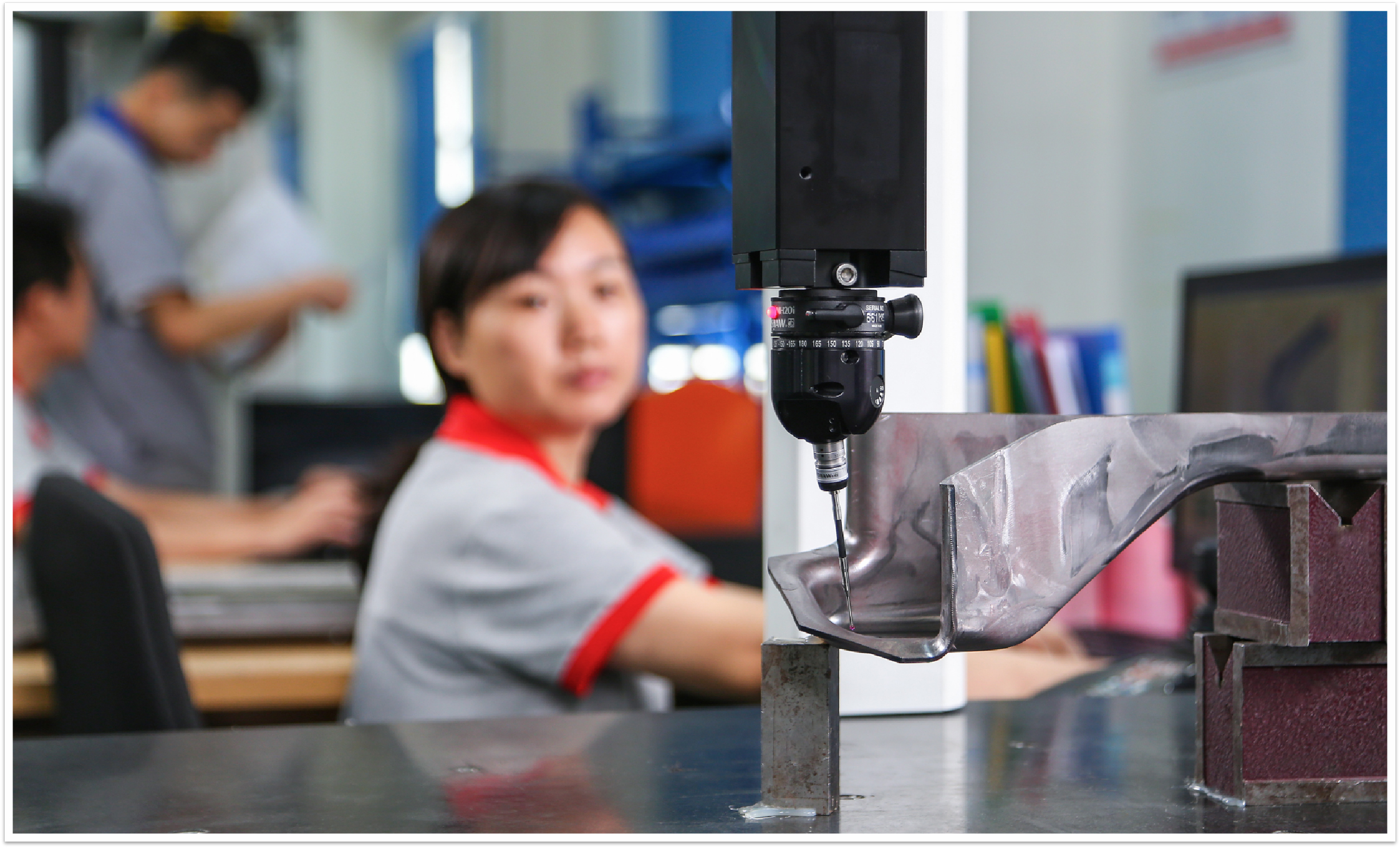

CMM Measurement Center For Casting Progressive Die

Our good trained personnel will take care every time in every program we have. We can do every requirement from the customer, to have the biggest satisfaction in the CMM as well.

3Sets of CMM, 2 Shifts/Day(10hrs per shift Mon-Sat)

CMM, 3000*1500*1000 , Leader CMM, 1200*600*600 , Leader Blue-light Scanner

CMM, 500*500*400, Hexagon 2D Projector, Hardness Tester

.png)

.png)