H Type Arc Robotic Welding Systems For Automotive Parts Assembly Line

Video

Product Details

| Place of Origin: | China |

| Brand Name: | Top Talent |

| Certification: | ISO 9001 2008 Certification |

| Model Number: | TTM16832-13 |

Payment & Shipping Terms

| Minimum Order Quantity: | 1 System |

| Price: | All the price can be negotiated |

| Packaging Details: | Depending on your request for High Precision Auto Checking Fixture |

| Delivery Time: | Shipped in 2-3 days after buyoff and payment |

| Supply Ability: | 5 System Per Annual |

|

1 Item: |

Arc Welding Room |

2 Item: |

Welding Gun Cleaner |

|

3 Item: |

Robot +Base |

4 Item: |

Trunking |

|

5 Item: |

Fixture |

6 Item: |

Shutter Doors |

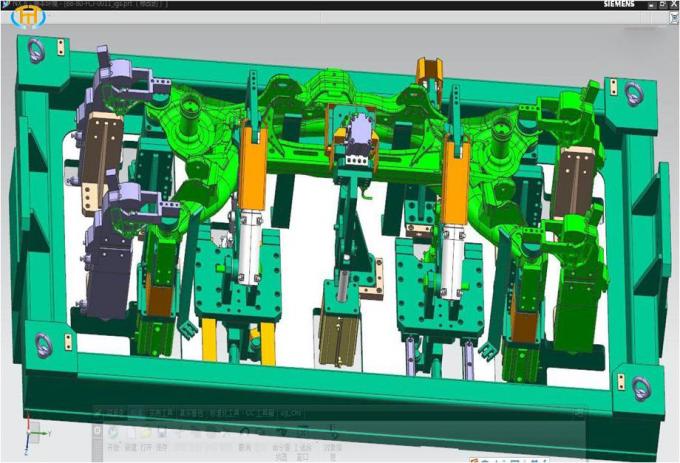

Arc Welding System For Automotive Part Production Process Customized

1. Arc Welding Room

2. Welding Gun Cleaner

3. Robot +Base

4. Trunking

5. Fixture

6. Shutter Doors

7. Welding Positioner

8. Button

9. Touch Screen

10.Safety Door

11.Wire Barrels

12. Welding Power

13.PLC Controller

14.Robot Control Cabinet

According to layout or running mode of the welding station, it can be divided into five categories: V type, Htype, line-type and horizontal rotation and vertical flip.

V type System

H type system

Line-type system

Horizontal rotation system

Vertical flip system

.png)

.png)