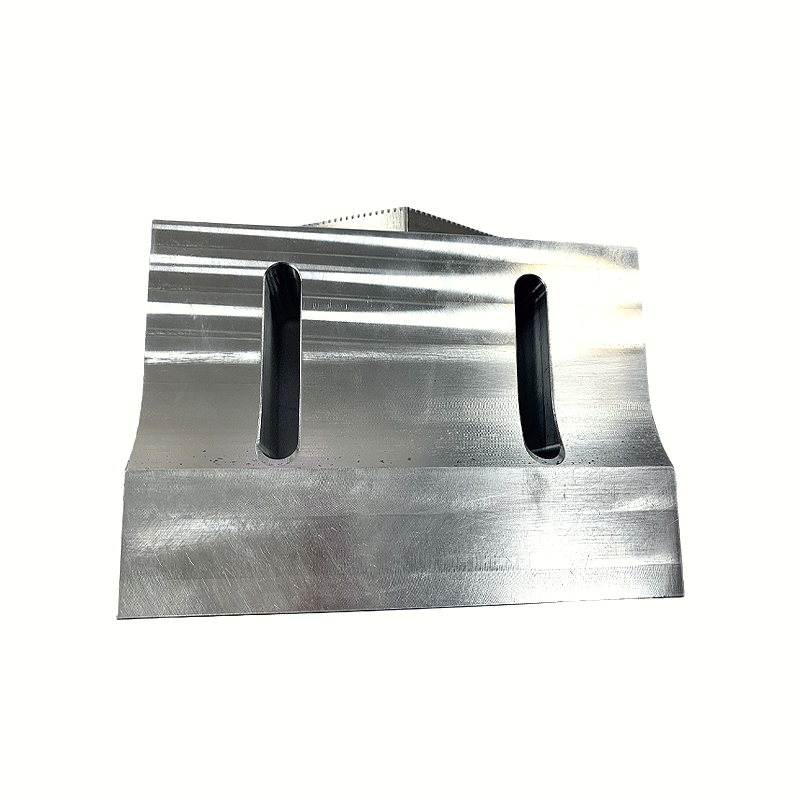

Factory wholesale Welding Table Accessories - Welding Fixture For Cross Member WS Spring Link – TTM

Factory wholesale Welding Table Accessories - Welding Fixture For Cross Member WS Spring Link – TTM Detail:

Application Fields

Automotive industry quality control

Automotive production line production capacity improve

Specification

|

Fixture Type: |

Arc Welding |

|

Size: |

1800x1300x900mm |

|

Weight: |

125KG |

|

Material: |

Main Construction: metal Support: metal |

|

Surface treatment: |

Base Plate: Electroplating Chromium and Black Anodized |

Product Details

Detailed Introduction

This is a batch of welding fixture of WL Cross Member WS Spring Link , totally in 2 sets, we made for our Canada customer.The spring chuck shank is a cylindrical fixture installed in a milling machine to imprison a drill or a milling cutter. Insert the chuck into the lock nut and gently screw the lock nut with the spring chuck onto the shank, connector or spindle. Depending on the elasticity of elastic steel to tighten, loose clamp convenient, mostly used for clamping light, medium load cutting tools. It is often used for clamping cutting tools such as end mills, drill bits, taps, reamers and center drills. Change the clamping range by changing the different collects.When clamping, the thread part of the spring chuck, lock nut and positioning surface and cone surface should be cleaned. During the installation of the chuck and lock nut, the chuck and lock nut must be tilted to a certain Angle and then placed into the lock slot of the lock nut. Do not use the extended powerful wrench torque is too tight, to prevent the meteorite bad tool and fixture.

The Working Flow

1. Received the purchasing order -——-> 2. Design -——-> 3. Confirming the drawing/solutions -——-> 4. Prepare the materials -——-> 5. CNC -——-> 6. CMM -——-> 6. Assembling -——-> 7. CMM-> 8. Inspection -——-> 9. (3rd part inspection if need) -——-> 10. (internal/customer on site) -——-> 11. Packing(wooden box) -——-> 12. Delivery

Manufacturing Tolerance

1. The Flatness of Base Plate 0.05/1000

2. The Thickness of Base Plate ±0.05mm

3. The Location Datum ±0.02mm

4. The Surface ±0.1mm

5. The Checking Pins and Holes ±0.05mm

Process

CNC Machining(Milling/Turning), Grinding

Electroplating Chromium and Black Anodized Treatment

Design Hours(h):40h

Build Hours(h):150h

Quality Control

CMM (3D Coordinate Measuring Machine), Vms-2515G 2D Projector, HR-150 A Hardness Tester

Third Party Certification done by ShenZhen Silver Basis Testing Technology Co., Ltd , ISO17025 Certified

Product detail pictures:

Related Product Guide:

We usually think and practice corresponding for the change of circumstance, and grow up. We aim at the achievement of a richer mind and body as well as the living for Factory wholesale Welding Table Accessories - Welding Fixture For Cross Member WS Spring Link – TTM , The product will supply to all over the world, such as: United States, Sweden, Sheffield, Our faith is to be honest first, so we just supply high quality products to our customers. Really hope that we can be business partners. We believe that we can establish long time business relationship with each other. You can contact us freely for more information and pricelist of our products ! You will be Unique with our hair products !!

Speaking of this cooperation with the Chinese manufacturer, I just want to say"well dodne", we are very satisfied.

1.png)

.png)

.png)