Factory wholesale Welding Fixtures & Jigs - Automotive Automated Production Assembling Systems , Line Type Arc Welding Systems – TTM

Factory wholesale Welding Fixtures & Jigs - Automotive Automated Production Assembling Systems , Line Type Arc Welding Systems – TTM Detail:

Product Details

| Place of Origin: | China |

| Brand Name: | Top Talent |

| Certification: | ISO 9001 2008 Certification |

| Model Number: | TTM18023-15 |

Payment & Shipping Terms

| Minimum Order Quantity: | 1 System |

| Price: | All the price can be negotiated |

| Packaging Details: | Depending on your request for High Precision Auto Checking Fixture |

| Delivery Time: | Shipped in 2-3 days after buyoff and payment |

| Supply Ability: | 5 Systems |

|

7 Item: |

Electrode Modifier |

8 Item: |

Trunking |

|

9 Item: |

The Robot Base + Robot |

10 Item: |

Electrical Cabinet |

|

11 Item: |

Safety Door |

12 Item: |

Valve Control Cabinet |

Automotive Automated Production Assembling Systems , Line Type Arc Welding Systems

1. Arc Welding Room

2. Welding Gun Cleaner

3. Robot +Base

4. Trunking

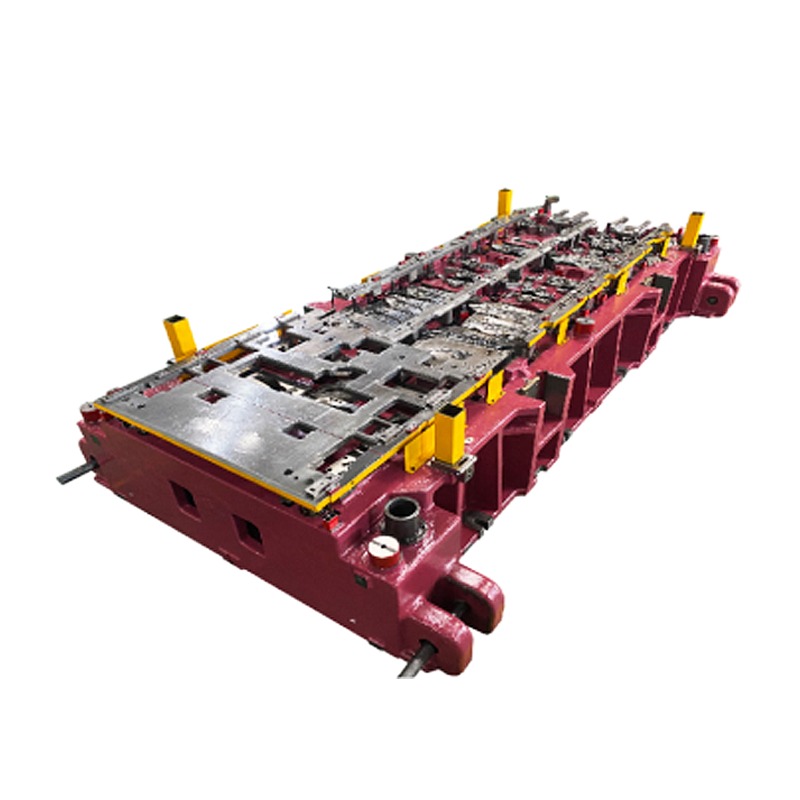

5. Fixture

6. Shutter Doors

7. Welding Positioner

8. Button

9. Touch Screen

10.Safety Door

11.Wire Barrels

12. Welding Power

13.PLC Controller

14.Robot Control Cabinet

According to layout or running mode of the welding station, it can be divided into five categories: V type, Htype, line-type and horizontal rotation and vertical flip.

V type System

H type system

Line-type system

Horizontal rotation system

Vertical flip system

Project introduction

The robots of welding robots adopt well-known brands and have anti-collision and addressing functions, coordination functions of external control axes and robots, welding machines using MAG digital welding machines, robot welding fixtures using gas-controlled electric inspection, and robot station offices using Line-type layouts.

With two sides on the top, the robot keeps spinning and the robot is extremely efficient.

Tag

robotic welding machine,robotic welding equipment

Product detail pictures:

Related Product Guide:

We have now sophisticated machines. Our solutions are exported to the USA, the UK and so on, enjoying a great reputation amid consumers for Factory wholesale Welding Fixtures & Jigs - Automotive Automated Production Assembling Systems , Line Type Arc Welding Systems – TTM , The product will supply to all over the world, such as: Cairo, Florence, Singapore, We welcome customers from all over the world come to discuss business. We supply high quality products, reasonable prices and good services. We hope to sincerely build business relationships with customers from at home and abroad, jointly striving for a resplendent tomorrow.

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.

.png)

.png)