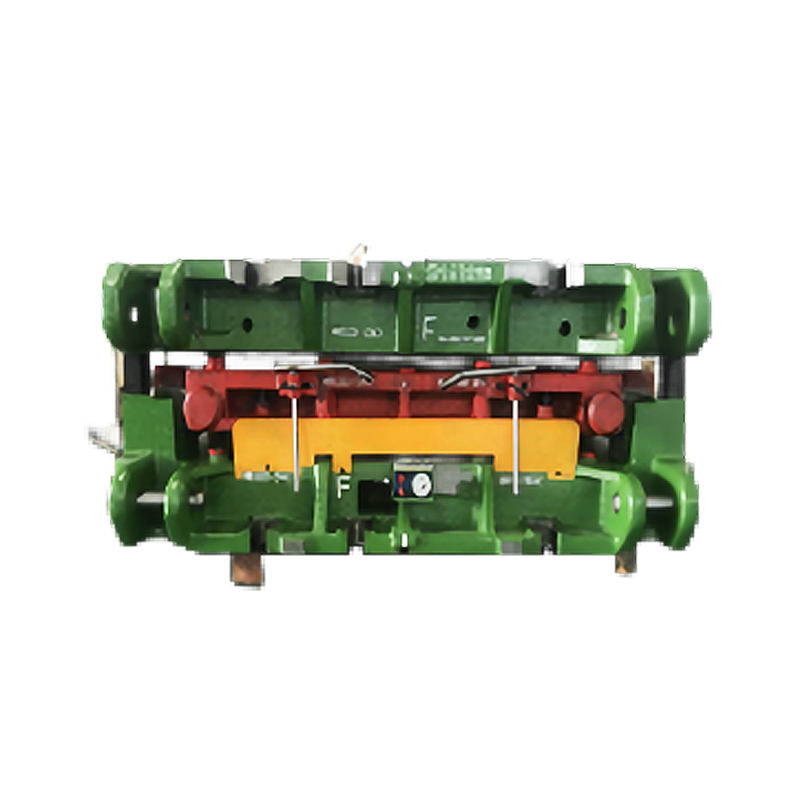

Factory wholesale Attribute Checking Fixtures - Casting Aluminium Parts Checking Fixtures – TTM

Factory wholesale Attribute Checking Fixtures - Casting Aluminium Parts Checking Fixtures – TTM Detail:

Function

For Casting Aluminium Parts quality inspection control and support to improve the automotive production line capacity rate

Specification

|

Fixture Type: |

Casting Aluminium Parts Checking Fixtures |

|

Size: |

1240*980*1180 |

|

Weight: |

120KG |

|

Material: |

Main Construction: metal Support: metal |

|

Surface treatment: |

Base Plate: Electroplating Chromium and Black Anodized |

Detailed Introduction

Automobile quality is closely related to driving safety, so it needs to go through strict measurement process in the production process. As the work of measuring the quality of automobile parts, the manufacturing accuracy of the inspection tool itself is very important, and it is necessary to complete the high standard appearance function and accuracy measurement before leaving the factory. With excellent measuring ability, the CMM measuring function of provides guarantee for the quality acceptance of inspection tools.

This time, we need to measure an auto parts inspection tool, and we need to measure the positioning hole, clamping block and profile. Because of the large volume and weight of the workpiece, the Function plus gantry three coordinate is selected as the measuring model. This model has a large stroke, which can complete the detection and assembly detection of the tool assembly, and can directly put the workpiece on the platform to measure while assembling and adjusting.

It is necessary to construct a circle to measure the mounting hole and positioning hole. After the measurement, the position and aperture of the hole center are evaluated. When measuring the clamping block, select the corresponding position on the digital modulus, and then let the measuring machine automatically measure and complete the evaluation of position degree and normal deviation T value. With PC-DMIS software, the profile measurement can be completed by measuring edge points when the Angle between zero plane and five plane is 90°. The edge point features can be selected on the software, and the position deviation can be evaluated after the measurement. After the completion of all the measurement work, the test report with text and text can be output, and the measurement results of the instrument can be learned at a glance.

The excellent combination of hardware and software ensures the reliability of CMM of . The hardware adopts professional control system, diagonal beam, precision long guide rail, PTB certified grating, and the software adopts the industry benchmark PC-DMIS software. The authoritative tolerance evaluation ability and intelligent feature recognition function can help customers quickly improve the coordinate measurement ability.

The Working Flow

1. Received the purchasing order -——-> 2. Design -——-> 3. Confirming the drawing/solutions -——-> 4. Prepare the materials -——-> 5. CNC -——-> 6. CMM -——-> 6. Assembling -——-> 7. CMM-> 8. Inspection -——-> 9. (3rd part inspection if need) -——-> 10. (internal/customer on site) -——-> 11. Packing(wooden box) -——-> 12. Delivery

Manufacturing tolerance

1. The Flatness of Base Plate 0.05/1000

2. The Thickness of Base Plate ±0.05mm

3. The Location Datum ±0.02mm

4. The Surface ±0.1mm

5. The Checking Pins and Holes ±0.05mm

Product detail pictures:

Related Product Guide:

Our personnel are always inside the spirit of "continuous improvement and excellence", and together with the outstanding excellent goods, favorable price and good after-sales services, we try to gain every customer's trust for Factory wholesale Attribute Checking Fixtures - Casting Aluminium Parts Checking Fixtures – TTM , The product will supply to all over the world, such as: Brasilia, Moscow, Pretoria, By integrating manufacturing with foreign trade sectors, we can provide total customer solutions by guaranteeing the delivery of right products to the right place at the right time, which is supported by our abundant experiences, powerful production capability, consistent quality, diversified products and the control of the industry trend as well as our maturity before and after sales services. We'd like to share our ideas with you and welcome your comments and questions.

This manufacturers not only respected our choice and requirements, but also gave us a lot of good suggestions, ultimately, we successfully completed the procurement tasks.

1.png)

.png)

.png)