Factory Supply Jig And Fixture - Carbon Fibre Custom Carbon Fibre checking fixtures – TTM

Factory Supply Jig And Fixture - Carbon Fibre Custom Carbon Fibre checking fixtures – TTM Detail:

Function

For Carbon Fibre quality inspection control and support to improve the automotive production line capacity rate.

Specification

|

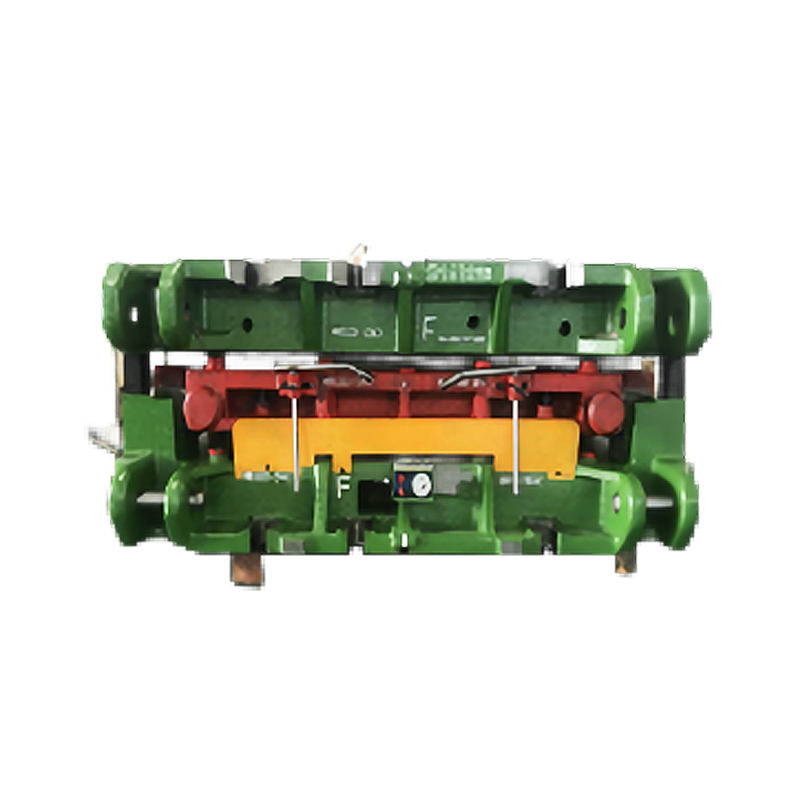

Fixture Type: |

Assembly Carbon Fibre Part Checking Fixtures |

|

Size: |

1700x1200x600mm |

|

Weight: |

145KG |

|

Material: |

Main Construction: metal Support: metal |

|

Surface treatment: |

Base Plate: Electroplating Chromium and Black Anodized |

Detailed Introduction

That are needed in many areas of our fixture, our electronic industry and machinery industry, in particular, it is a clear standard for the size of the product, the fixture can very good help we could check staff, that with the excellent performance of carbon fiber composites, the fixture on the market also appeared a lot of carbon fiber composites of carbon fiber fixture, Carbon fiber inspection tools have the following three advantages.

Advantage one: excellent machining performance

Submit the first requirement is to have good precision, such ability in the us in practice, better guarantee the performance advantages of itself, the carbon fiber fixture, have excellent plasticity, after forming, also has the very strong rigid demand, at the request of the special fixture, such as resistance to high temperature performance, The carbon fiber tester will not expand even in the high temperature environment, which ensures the stability of the carbon fiber tester and the accuracy of the tester.

Advantage two: stiffness performance is very good

Because of the special performance of carbon fiber composite material, the stiffness of carbon fiber test tool is better, the stiffness is several times of the traditional steel, the stiffness of carbon fiber test tool also makes carbon fiber can have better tensile strength and shear strength, and the higher the grade of carbon fiber mechanical performance is more obvious.

Advantage three: lighter quality

One of the most obvious characteristics of carbon fiber composite products is lighter weight. Carbon fiber composite material has very good weight reduction performance, with less than a quarter of the weight of steel, it is more convenient to use, which can well ensure its convenience. Under such circumstances, the inspection tool is easier to carry.

The Working Flow

1. Received the purchasing order -——-> 2. Design -——-> 3. Confirming the drawing/solutions -——-> 4. Prepare the materials -——-> 5. CNC -——-> 6. CMM -——-> 6. Assembling -——-> 7. CMM-> 8. Inspection -——-> 9. (3rd part inspection if need) -——-> 10. (internal/customer on site) -——-> 11. Packing(wooden box) -——-> 12. Delivery

Manufacturing Tolerance

1. The Flatness of Base Plate 0.05/1000

2. The Thickness of Base Plate ±0.05mm

3. The Location Datum ±0.02mm

4. The Surface ±0.1mm

5. The Checking Pins and Holes ±0.05mm

Product detail pictures:

Related Product Guide:

Sticking for the perception of "Creating products of top quality and producing friends with people today from all around the world", we constantly place the desire of shoppers to start with for Factory Supply Jig And Fixture - Carbon Fibre Custom Carbon Fibre checking fixtures – TTM , The product will supply to all over the world, such as: Argentina, Sydney, Kyrgyzstan, We now have been making our goods for more than 20 years . Mainly do wholesale , so we've the most competitive price , but highest quality. For the past years , we got very good feedbacks , not only because we offer good solutions , but also because of our good after-sale service . We are here waiting for yourself for your inquiry.

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.

.png)

.png)