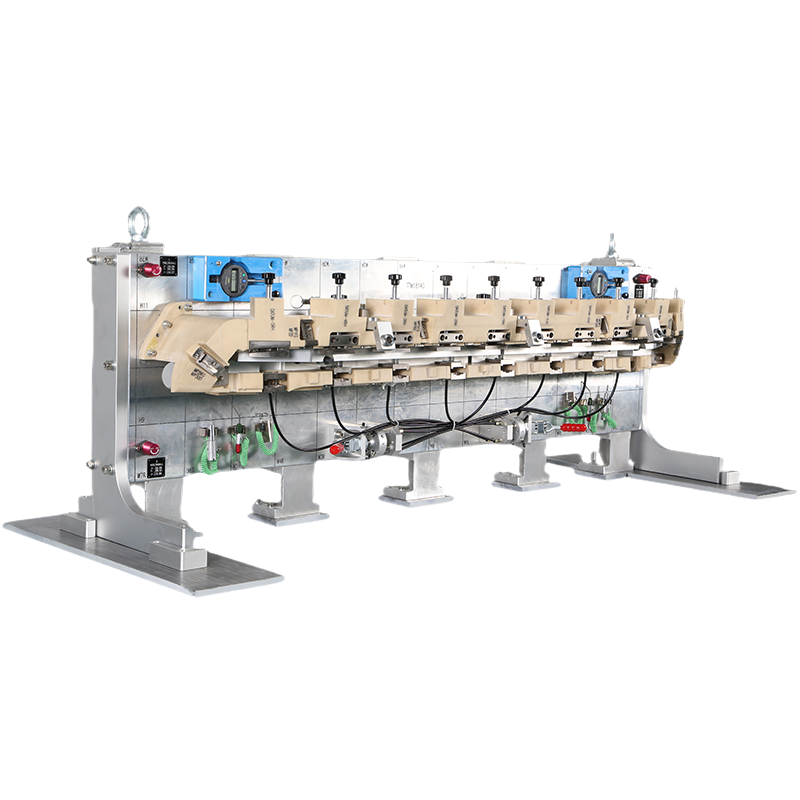

factory Outlets for Composite Lay-Up Fixtures - Checking Fixture for Door Inner Panel – TTM

factory Outlets for Composite Lay-Up Fixtures - Checking Fixture for Door Inner Panel – TTM Detail:

Function

For Door Inner Panel quality inspection control and support to improve the automotive production line capacity rate.

Specification

|

Fixture Type: |

Assembly Plastic Parts Checking Fixtures |

|

Size: |

1450*980*1180 |

|

Weight: |

145KG |

Product Details

Detailed Introduction

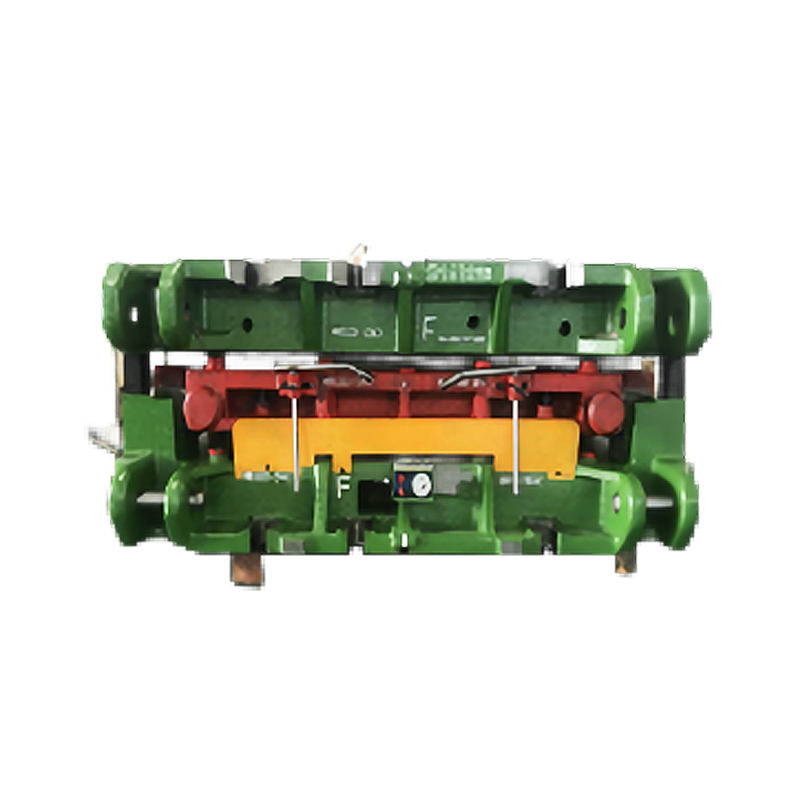

The invention relates to an automobile door plank with the fixture, including: bearing has a door plank on the adaptation of the contour, with cars along the inner edge has several support and car door plank of plug adapter plug column: outer contour box has a loose, on the surface of the outer contour box fixed on the pedestal of circumferential, outer contour box inner contour and car door measuring gap formed between the outer contour of: The outer edge of a plurality of lifting part ring outer contour frame is arranged, the lifting part is fixedly connected with the outer edge of the outer contour frame, and the lifting part can vertically lift the outer contour frame; The dial indicator seat is suspended on the outer contour frame, and a plurality of through-holes are provided on the dial indicator seat. Each through-hole is fixed with a dial indicator, and the end of the dial indicator is against the car door plate: measuring pen, measuring pen is cylindrical and its two cross-sectional diameters are respectively compatible with the measuring requirements. This kind of full contour detection tool for automobile door plate is convenient to realize the full contour detection of the piecework.

The Working Flow

1. Received the purchasing order -——-> 2. Design -——-> 3. Confirming the drawing/solutions -——-> 4. Prepare the materials -——-> 5. CNC -——-> 6. CMM -——-> 6. Assembling -——-> 7. CMM-> 8. Inspection -——-> 9. (3rd part inspection if need) -——-> 10. (internal/customer on site) -——-> 11. Packing(wooden box) -——-> 12. Delivery

After-Sales Services

A. Supplying Technical Documentation&Training

B. Supplying Spare Parts List

C. Recommended Spares & Replacement Parts

D. Reliability and Maintainability

E. Equipment Installation on Customer Site

F. Home-line Support/Production Support

G. Remote Technical Support for Commission/Problems Solving on Customer Site

Process

CNC Machining(Milling/Turning), Grinding

Electroplating Chromium and Black Anodized Treatment

Design Hours(h):40h

Build Hours(h):150h

Quality Control

CMM (3D Coordinate Measuring Machine), Vms-2515G 2D Projector, HR-150 A Hardness Tester

Third Party Certification done by ShenZhen Silver Basis Testing Technology Co., Ltd , ISO17025 Certified

Product detail pictures:

Related Product Guide:

We're committed to providing easy,time-saving and money-saving one-stop purchasing service of consumer for factory Outlets for Composite Lay-Up Fixtures - Checking Fixture for Door Inner Panel – TTM , The product will supply to all over the world, such as: Singapore, Korea, Bahamas, For many years, we have adhered to the principle of customer oriented, quality based, excellence pursuing, mutual benefit sharing. We hope, with great sincerity and good will, to have the honor to help with your further market.

The goods are very perfect and the company sales manager is warmful, we will come to this company to purchase next time.

.png)

.png)