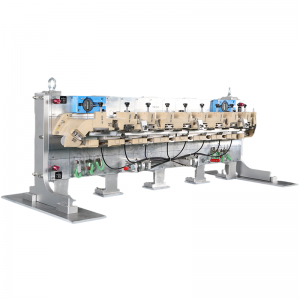

Door panel automotive inspection OEM plastic checking fixture design

Video

Specification

|

Fixture Type: |

Checking Fixture for Door Panel |

|

Size: |

1900*500*630mm |

|

Weight: |

250KG |

|

Material: |

Main Construction: metal Support: metal |

|

Surface treatment: |

Base Plate: Electroplating Chromium and Black Anodized |

Product Details

Detailed Introduction

This is a auto parts checking fixture according to the parts testing requirements to design, precision machining. Plastic is a polymer material with resin as the main component. Resin is divided into natural and synthetic two categories, plastic synthetic resin, according to the use of plastic can be divided into general plastics, engineering plastics and special purpose plastics. Plastic instrument is rich in sources, low cost, and has the advantages of low density, high specific strength, good insulation performance, chemical stability, vibration reduction and wear resistance.

Stamping is widely used in automobile main engine factories, plastic molding is widely used in parts factories:On the automobile, the parts covering the sheet metal parts of the body are collectively called inner and outer trim parts, which play a dual role of decoration and function. The manufacturing quality of automotive interior and exterior trim has a great influence on the quality of the vehicle, especially on the shape of the vehicle, so the inspection of its quality has become an essential work of the automobile factory. Much of the interior and exterior trim is plastic molding, such as the front and rear bumpers; Instrument panel: column interior and other easy to see, not easy to find plastic bracket: support; Cap; Small cover plate and trim plate and so on.

The Working Flow

1. Received the purchasing order -——-> 2. Design -——-> 3. Confirming the drawing/solutions -——-> 4. Prepare the materials -——-> 5. CNC -——-> 6. CMM -——-> 6. Assembling -——-> 7. CMM-> 8. Inspection -——-> 9. (3rd part inspection if need) -——-> 10. (internal/customer on site) -——-> 11. Packing(wooden box) -——-> 12. Delivery

Manufacturing Tolerance

1. The Flatness of Base Plate 0.05/1000

2. The Thickness of Base Plate ±0.05mm

3. The Location Datum ±0.02mm

4. The Surface ±0.1mm

5. The Checking Pins and Holes ±0.05mm

.png)

.png)