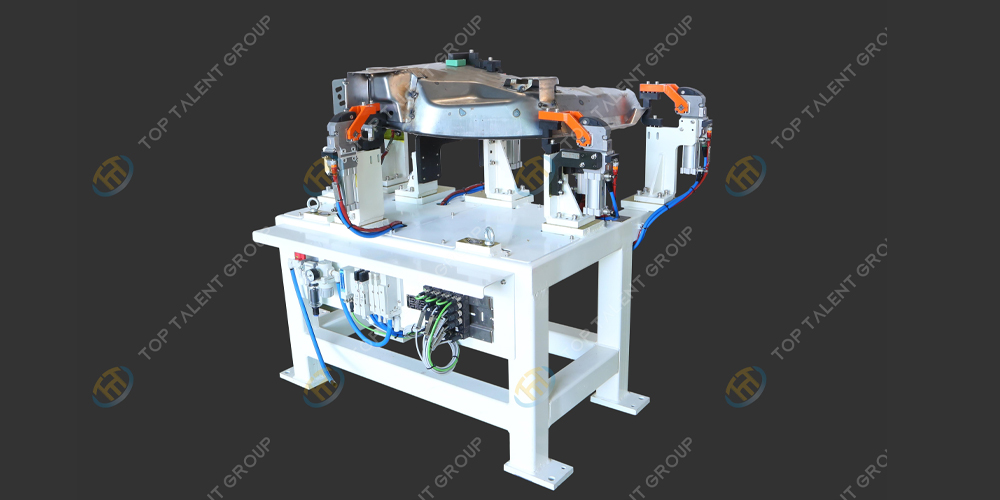

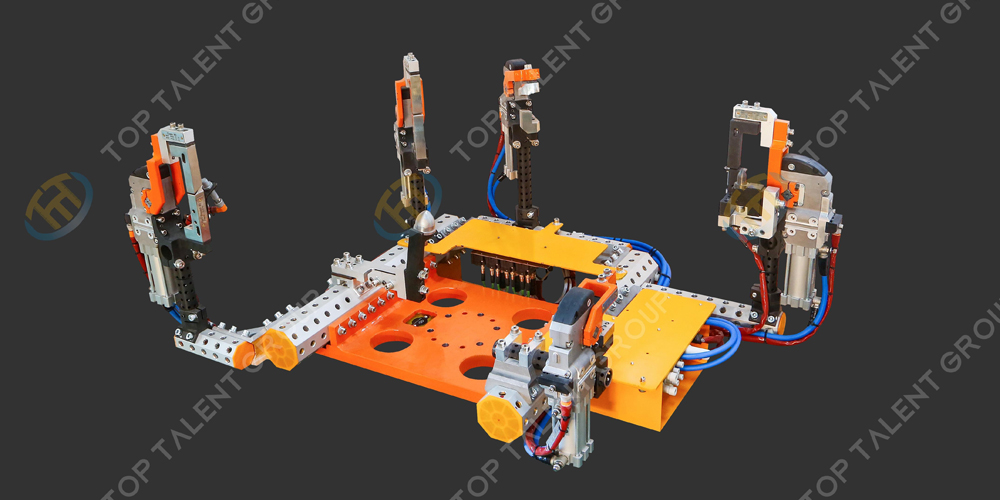

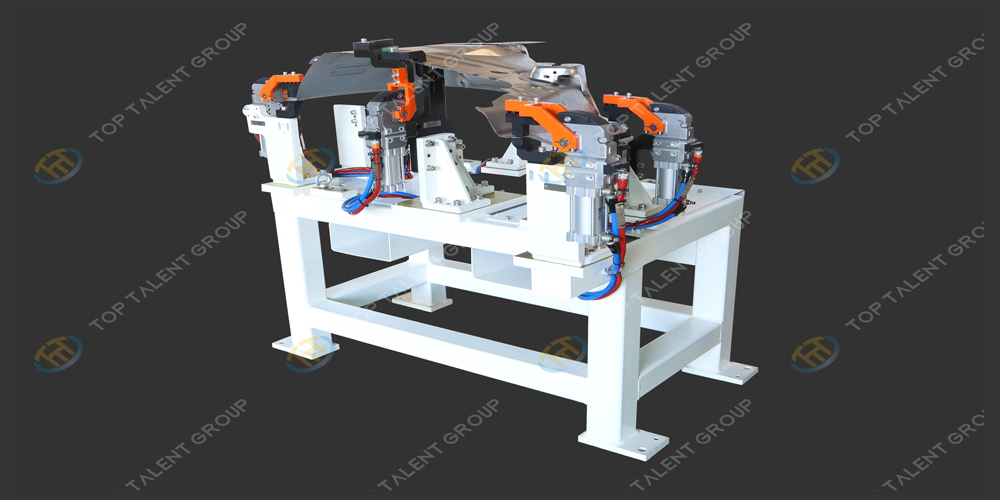

Customized Welding Lines Wheel House Arc Pneumatic Welding Fixture

Video

Essential details

|

Welding Type: |

Arc Welding |

|

Material: |

Metal |

|

Welding Fixtures: |

4 Sets Gripers: 2 Sets |

|

Exporting Counties: |

Canada |

|

Year: |

2020 |

Production Pictures

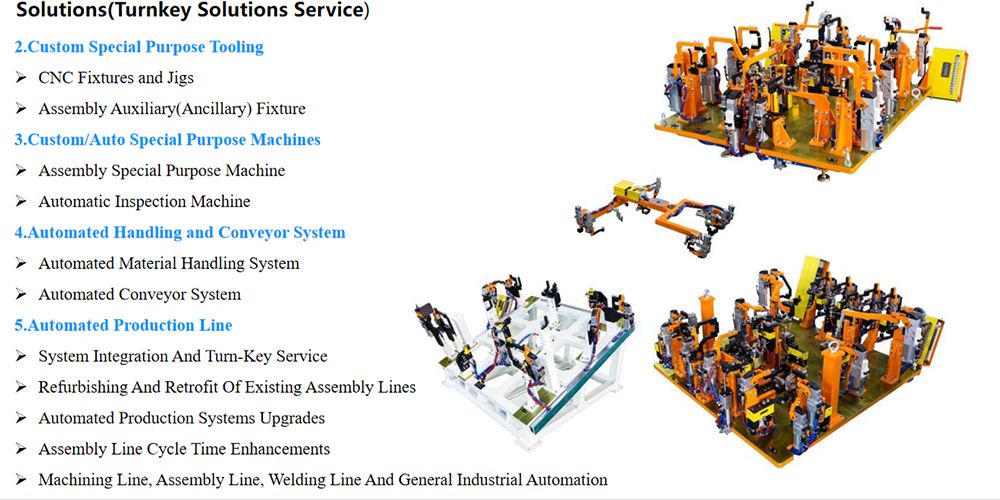

Introduction

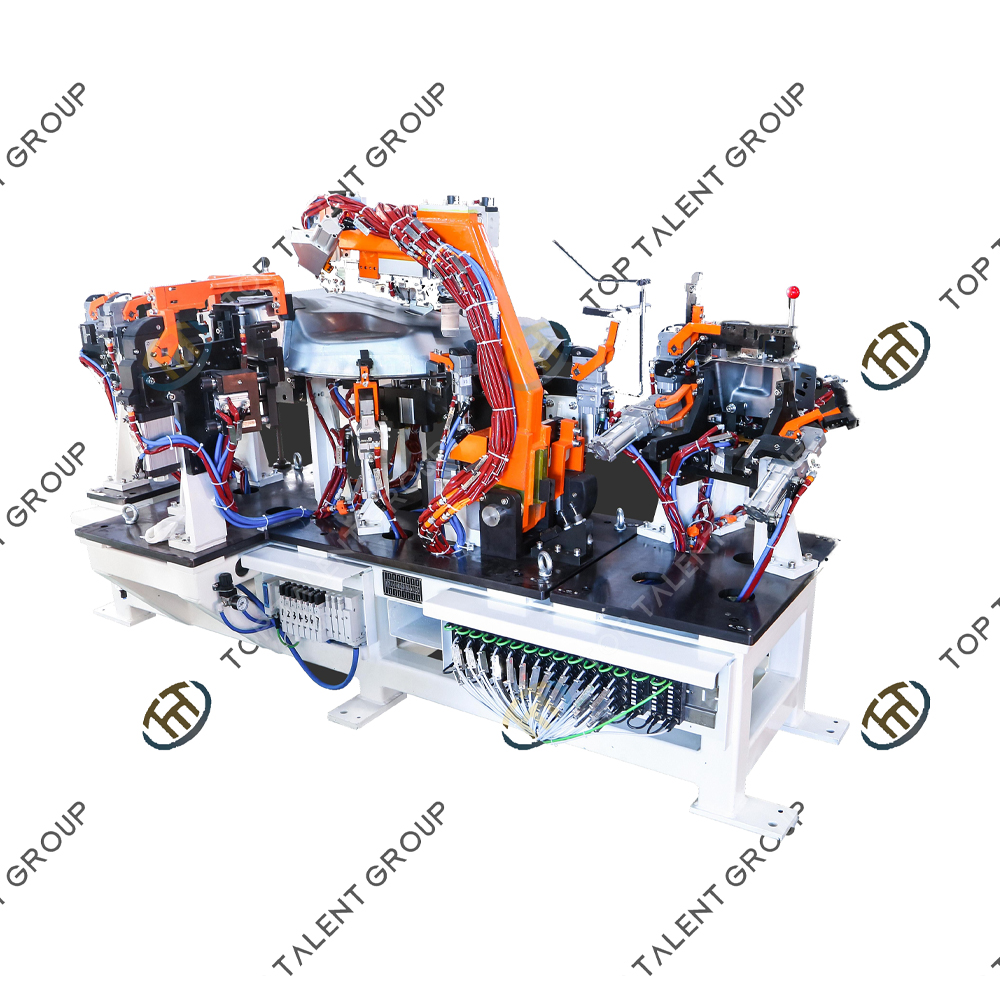

The Wheel House Welding Fixture produced by TTM adopts a mechanical clamping method to ensure the accuracy of the position and angle of the wheel cover. It can be used in conjunction with welding robots and other automated equipment to achieve efficient and stable wheel house welding operations. At the same time, it can also ensure the welding quality and avoid deformation and offset of the wheel housing during the welding process, thereby improving the quality and performance of the entire car body.

In a word, the Wheel House Welding Fixture is a very important fixture in the automobile manufacturing industry. It can improve the efficiency and quality of body welding, and it is an indispensable key component in the modern automobile production line.

Our Working Flow

1. Received the purchasing order -——-> 2. Design -——-> 3. Confirming the drawing/solutions -——-> 4. Prepare the materials -——-> 5. CNC -——-> 6. CMM -——-> 6. Assembling -——-> 7. CMM-> 8. Inspection -——-> 9. (3rd part inspection if need) -——-> 10. (internal/customer on site) -——-> 11. Packing(wooden box) -——-> 12. Delivery

Manufacturing Tolerance

1. The Flatness of Base Plate 0.05/1000

2. The Thickness of Base Plate ±0.05mm

3. The Location Datum ±0.02mm

4. The Surface ±0.1mm

5. The Checking Pins and Holes ±0.05mm

.png)

.png)