Customized Robotic Welding Systems With Spot Welding Fixture For Automotive Parts

Video

Product Details

| Place of Origin: | China |

| Brand Name: | Top Talent |

| Certification: | ISO 9001 2008 Certification |

| Price: | All the price can be negotiated |

| Packaging Details: | Depending on your request for High Precision Auto Checking Fixture |

| Delivery Time: | Shipped in 2-3 days after buyoff and payment |

| Supply Ability: | 15 Group |

|

A Switching Device: |

With Simple Structure Is Easy To Switch, But Has Reltively Low Repeating Accuracy And High Requirements Of Groud Flatness. |

B Switching Device: |

B Switch Device Has Similar Structure With A Mechanish And Avoid The Problem Of Low Repeating Accuracy. |

|

C Switching Device: |

C Switch Device Needs The Assistance Of Forklift And A Special Jig Storage. |

D Switching Device: |

D Switch Device Has The Advantages Of Easy Switching, High Accuracy. |

|

E Switching Device: |

E Switch Device Has Exquisite Structure Design, High Repeating Accuracy And Easy Switching. |

Spot Welding Systems: |

Structure Simple And Easy To Operate |

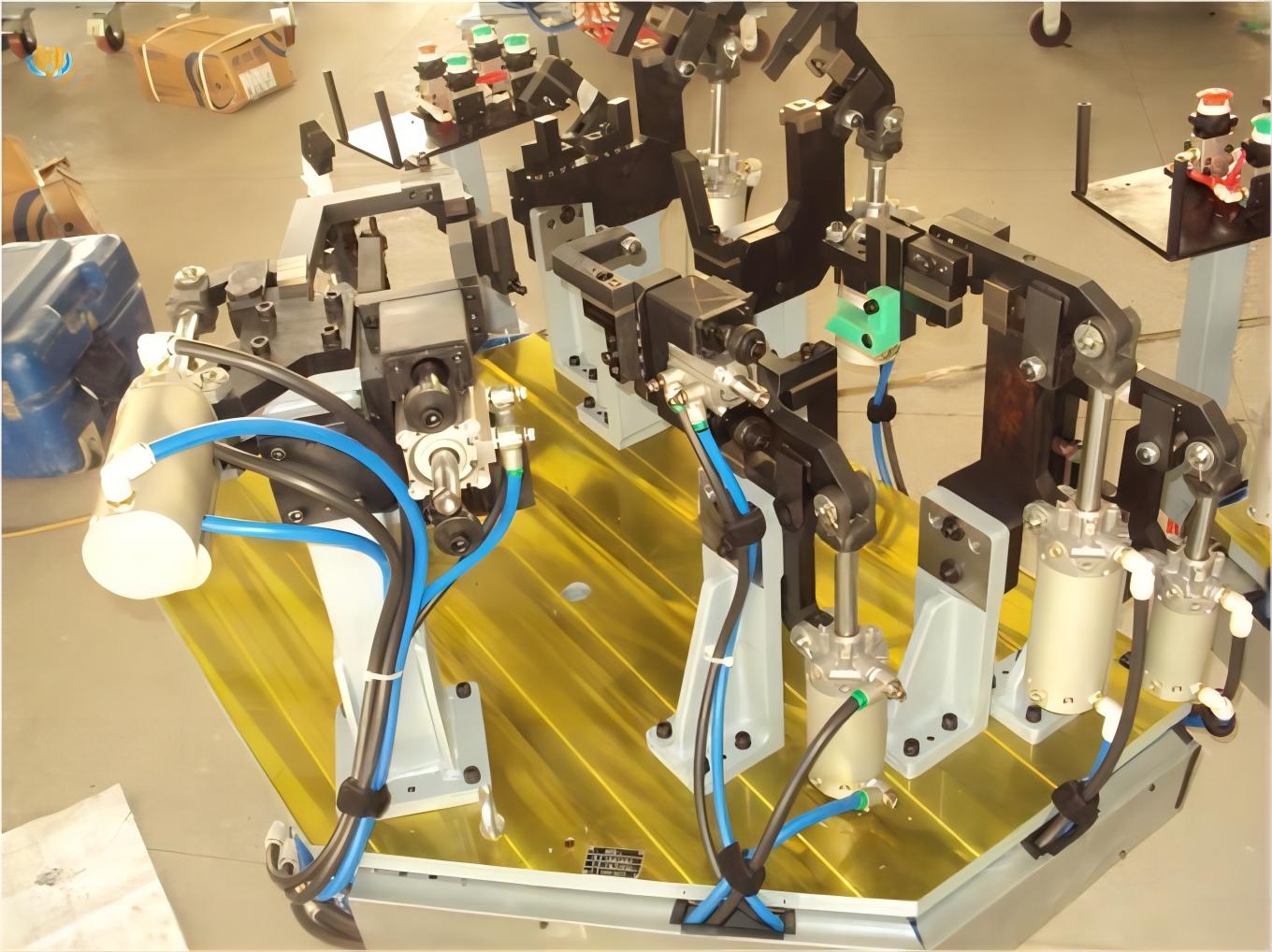

Customized Robotic Welding Systems Simple Assemble Spot Welding Fixture For Automotive Parts

1.The Periphery

2.Robot Control Cabinet + Welding Control Cabinet

3.Control Cabinet

4.Water and Gas Station

5.Fixture Switching Device

6.Fixture

7.Electrode Modifier

8.Trunking

9.The Robot Base + Robot

10.Electrical Cabinet

11.Safety Door

12.Valve Control Cabinet

13.Tricolor Indicator Light

14.Safety Grating

15.Touch Screen

16.Button Box

17.Security Door Indicator Light

Project introduction

The robots of welding robots adopt well-known brands and have anti-collision and addressing functions, coordination functions of external control axes and robots, welding machines using MAG digital welding machines, robot welding fixtures using gas-controlled electric inspection, and robot station offices using H-type layouts.

With two sides on the top, the robot keeps spinning and the robot is extremely efficient.

.png)

.png)