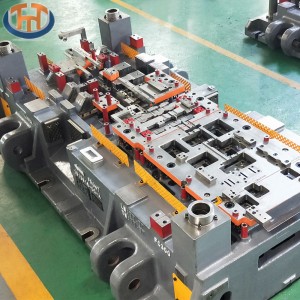

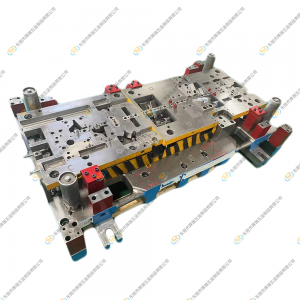

Custom Automotive Metal Parts And Car Components Progressive Die

Company Development

- In 2011, TTM was founded in ShenZhen.

- In 2012, Moving to DongGuan; Building cooperation relationship with Magna International Inc.

- In 2013 Introducing more advanced equipments.

- In 2016, Introduced large-scale CMM equipment and 5 axis CNC equipment; Cooperated with OEM Ford Completed Porsche, Lamborghini and Tesla CF projects.

- In 2017, Moving to current plant location; CNC was increased from 8 to 17 sets. Top Talent Automotive Fixtures & Jigs Co.Ltd was established

- In 2018, Cooperated with LEVDEO automotive and completed the automotion production line. 4-axis high-speed CNC was introduced, the total Qty of CNC reached 21.

- In 2019, Dongguan Hong Xing Tool & Die Manufacturer Co.,Ltd was established. (One stop service) Cooperated with Tesla Shanghai and Sodecia Germany. Built a new R&D laboratory for automation.

- In 2020, Cooperated with OEM ISUZU in SA ;Completed the RG06 One-Stop Service.

- In 2021, Moving forward with the quality belief to create a world-class enterprise.

- In 2022, TTM Group office was founded in Dongguan City, New CNC 4 axis*5 sets, New Press*630 tons, Hexagon Absolute Arm.

- In 2023, TTM is building a new plant for checking fixture&welding fixture business; adding one 2000T press.

Checking Fixture & Welding Jigs Factory (Total area: 9000m² )

Stamping Dies & Tools and Machined Parts Factory (Total area: 16000m²)

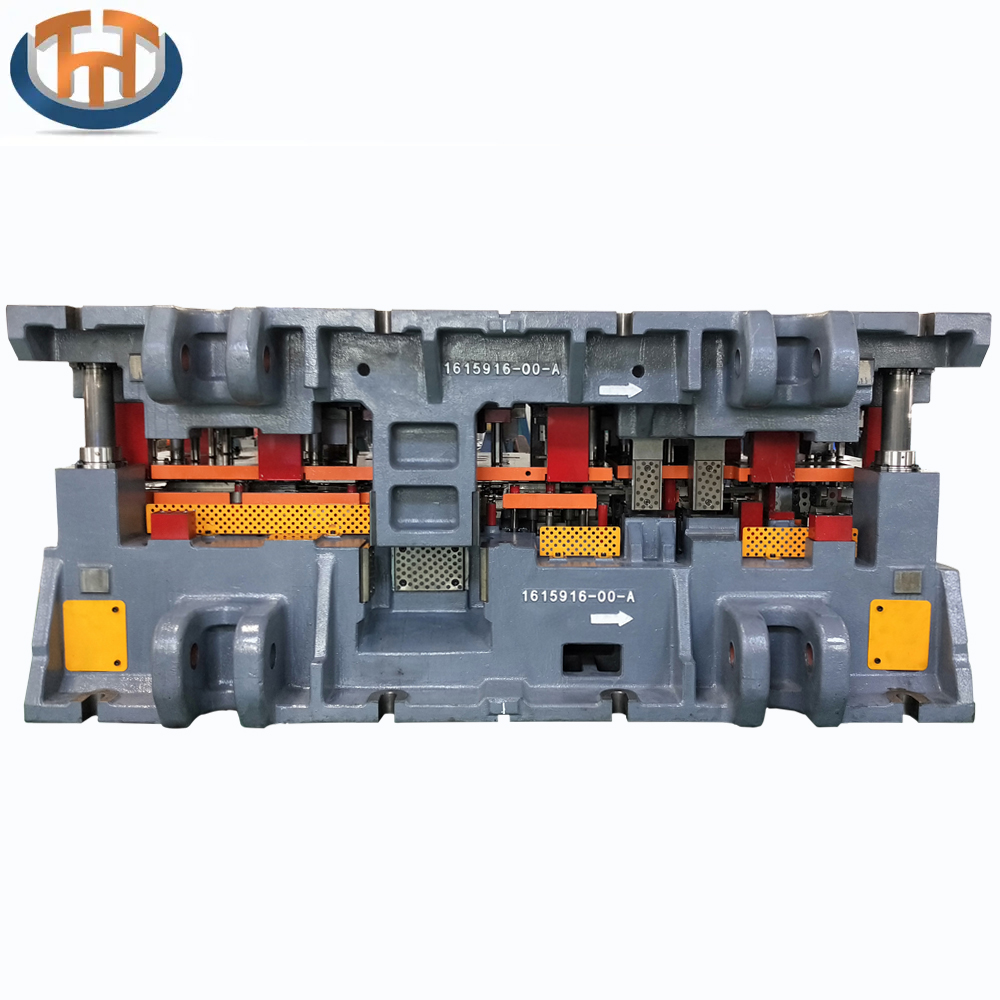

Products Description

| Product Name | Progressive die |

| Tolerance | Mating trim & form +/- 0.8mm, hole 0.6mm, genera trim & form +/- 1.5mm. |

| Material | DP780 CR420 etc. |

| Design Software | Catia, UG, Autoform |

| Part Application | CCB, SEATING and FLOOR progressive dies |

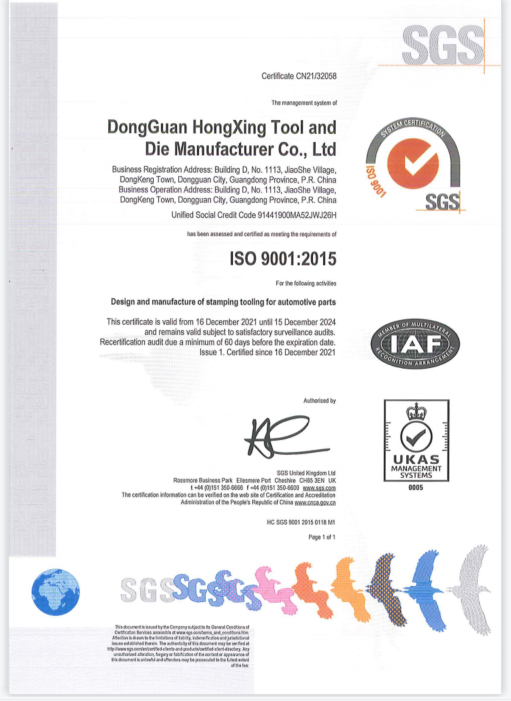

| Standard | IS09001 |

| Die Type | Compound Die, Transfer Die, Progressive die, Gang die or Tandem Die according to the customer's requirements |

| First Trial | 8-12 weeks after design approved |

| Die Life | Depends on customer’s production capacity |

| Quality confirm | CMM/Blue light scan report, also welcome customer to buy off on-site as per standard |

| Package | Plastic or wooden box for samples, wooden plate for stamping die or as per customer's requirements |

Progressive dies offer numerous advantages in metalworking and sheet metal manufacturing processes, making them a preferred choice for high-volume production. High Efficiency: Progressive dies are incredibly efficient, as they perform multiple operations on a single strip of sheet metal in a continuous process. This minimizes downtime and maximizes output, resulting in high production rates. Reduced Material Waste: The incremental forming process of progressive dies minimizes material waste. Unlike traditional methods that cut and shape individual pieces from large sheets, progressive dies optimize material usage by producing parts in a continuous strip. Cost-Effective: Their efficiency and reduced material waste make progressive dies cost-effective for high-volume production. Lower material and labor costs, along with high productivity, contribute to overall cost savings. High Precision: Progressive dies ensure a high degree of precision and consistency in the parts they produce. The tooling is designed to meet strict dimensional tolerances, resulting in high-quality components with minimal variation. Complex Part Production: These dies are versatile and capable of creating complex parts with multiple features, such as holes, slots, bends, and extrusions, all in a single pass. This versatility is invaluable for industries that require intricate and customized components. Fast Production: Progressive dies are ideal for rapid production, thanks to their ability to perform various operations simultaneously. The progressive nature of the process means that parts are continuously produced as the strip advances through the die.Automated Operation: Progressive die stamping is often automated, with mechanical or hydraulic presses used to advance the material strip through the die. Automation increases production speed, reduces manual labour, and enhances worker safety.Consistency: The precision and repeatability of progressive dies ensure that every part produced is nearly identical. This consistency is crucial for industries where tight tolerances are essential, such as automotive and aerospace manufacturing. Reduced Lead Times: By streamlining the production process and minimizing the need for multiple tool setups, progressive dies reduce lead times, allowing manufacturers to respond quickly to changing market demands. Scalability: Progressive dies can be scaled up or down to accommodate different production volumes. This adaptability makes them suitable for both small and large batch sizes, providing flexibility in manufacturing. Reduced Secondary Operations: The ability to perform various operations in one pass reduces the need for secondary processes, saving time and resources. This can result in a simplified production line. Enhanced Tool Life: Proper maintenance and design considerations can extend the lifespan of progressive dies. Their durability makes them a cost-effective long-term solution for high-volume production.

In summary, progressive dies are a cornerstone of modern manufacturing due to their high efficiency, cost-effectiveness, precision, and versatility. Their ability to produce complex parts rapidly with minimal material waste and their compatibility with automation make them a preferred choice for a wide range of industries.

ISO Management System For Progressive Die

Our Automotive progressive Die Team

We have more than 352 employees, 80% of which are senior technical engineers. Stamping die division: 130 employees, Welding fixture division:60 employees, Checking fixture division:162 employees, We have a professional sales & project management team, long-term service overseas projects, from RFQ to production, shipment, after-sales, our team can handle all problems for our customers in Chinese, English and German Language.

Our Advantages

1.Rich experience in automatic manufacturing and enterprise management.

2.One Stop Service for progressive die, checking fixture, welding fixtures and cells to achieve timing and cost saving, communication convenience, to maximize customer profits.

3.Professional engineering team to finalize the GD&T between single part and assembly component.

4.Turnkey Solution Service-Stamping progressive dies, Checking Fixture, Welding Fixtures and Cells with one team.

5.Strong capability with international technical support and partnership cooperation.

6.Big capacity: Checking Fixture, 1500 sets/year;Welding Fixture/Cells, 400-600 sets/year; Progressive Dies, 200-300 sets/year.

Major Projects Experience Of Progressive Dies

| Item | Year | Project | Tool Q'ty | District |

| 1 | 2021 | GM-A100 | 10 | Mexico |

| 2 | 2021 | C234 | 4 | Mexico |

| 3 | 2021 | Cover carry / Battery Bracket | 18 | South Africa |

| 4 | 2021 | Q20-066 | 12 | USA / Canada |

| 5 | 2021 | VW/AUDI | 10 | Mexico |

| 6 | 2021 | TESLA | 5 | Mexico |

| 7 | 2022 | TESLA MODEL Y | 12 | USA / Mexico |

| 8 | 2022 | Audi Q5 | 9 | Mexico |

| 9 | 2022 | GM C223-L232 | 16 | Mexico |

| 10 | 2022 | DAIMLER_MMA P04562 | 6 | Germany |

| 11 | 2022 | Ford P703 Refurbish tool | 18 | South Africa |

| 12 | 2022 | FMCSA P703M | 7 | South Africa |

| 13 | 2022 | Tooling ISRI | 6 | Brazil |

| 14 | 2022 | JETTA PA2 PROYECT | 6 | USA / Mexico |

| 15 | 2022 | Audi 192C | 8 | USA / Mexico |

| 16 | 2022 | BMW | 5 | Czech Republic |

| 17 | 2022 | VW TYRON | 6 | Mexico |

| 18 | 2022 | Daimler AG | 6 | Germany |

We can build all kinds of different size progressive dies including large size as we have big CNC Machines. With a variety of mechanical equipment such as milling, grinding, wire cutting machines and drilling machines, we can effectively and accurately control the processing process.

Progressive Die Manufacturing Center

25 sets of CNC with 2 shift running

1 Set of 3-Axis CNC 3000*2000*1500

1 Set of 3-Axis CNC 3000*2300*900

1 Set of 3-Axis CNC 4000*2400*900

1 Set of 3-Axis CNC 4000*2400*1000

1 Set of 3-Axis CNC 6000*3000*1200

4 Set of 3-Axis CNC 800*500*530

9 Set of 3-Axis CNC 900*600*600

5 Set of 3-Axis CNC 1100*800*500

1 Set of 3-Axis CNC 1300*700*650

1 Set of 3-Axis CNC 2500*1100*800

5 Axis CNC -Machine

4 Axis CNC -Machine

Progressive Die Assembly Center

CMM Measurement Center For Progressive Dies

Our good trained personnel will take care every time in every program we have. We can do every requirement from the customer, to have the biggest satisfaction in the CMM as well.

3Sets of CMM, 2 Shifts/Day(10hrs per shift Mon-Sat)

CMM, 3000*1500*1000 , Leader CMM, 1200*600*600 , Leader Blue-light Scanner

CMM, 500*500*400, Hexagon 2D Projector, Hardness Tester

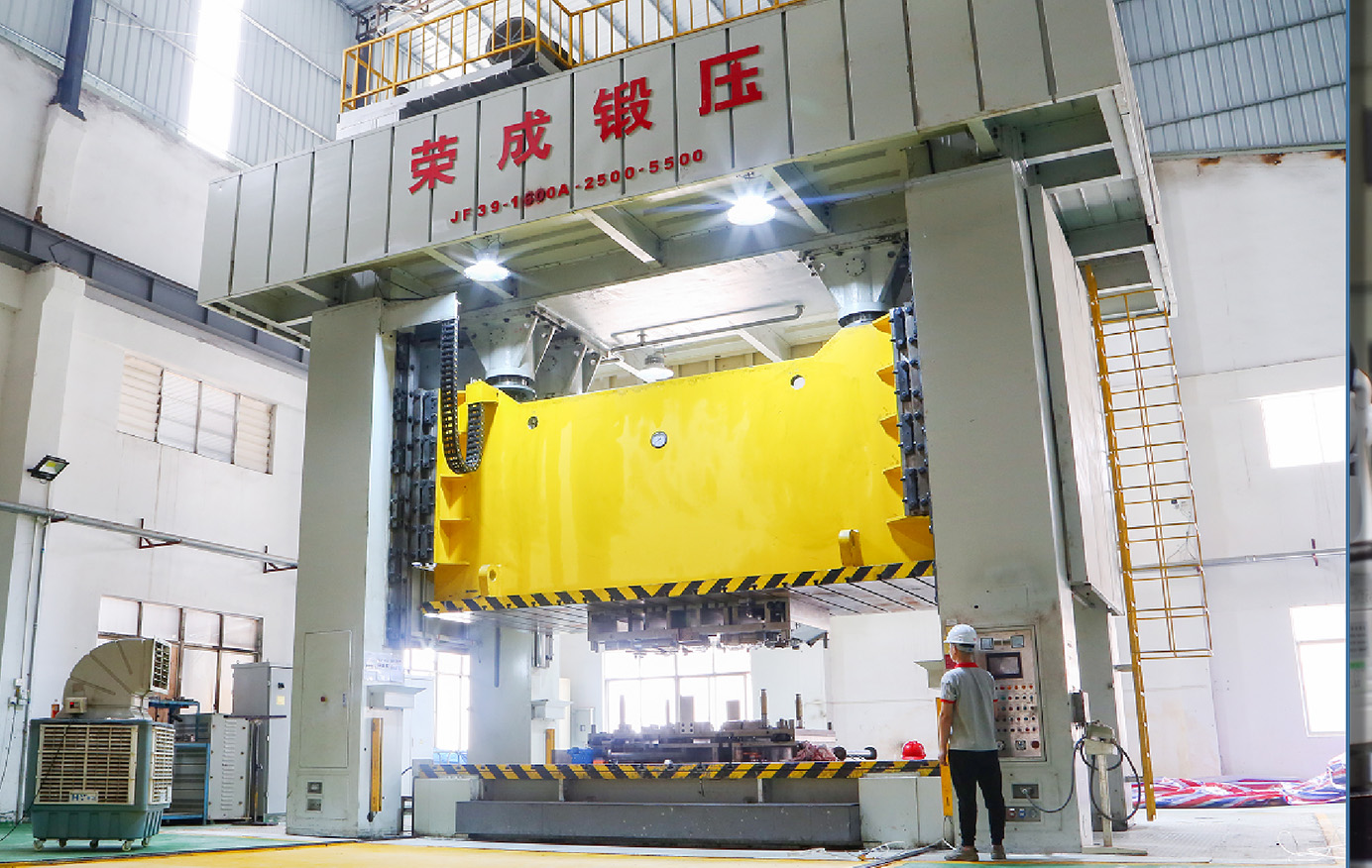

Progressive Die Press Center

Tonnage 1250T: Bolster size :5500*2500 with coil feeder

Tonnage 630T: Bolster size :4000*2000 with coil feeder

.png)

.png)