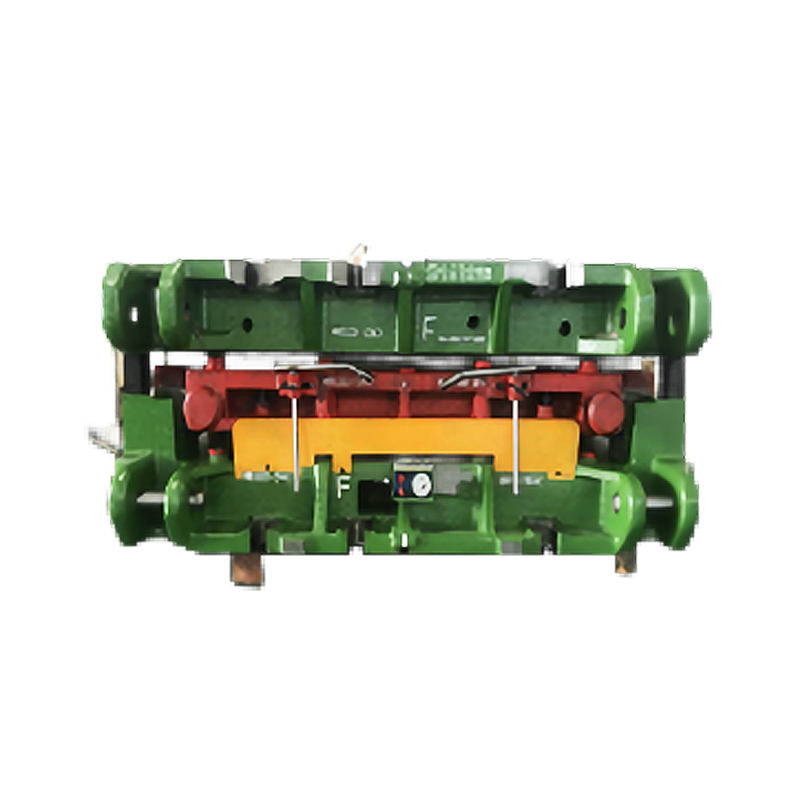

Best-Selling Machining Fixtures - Gom fixture For Fender ,Casting Aluminium Parts Checking Fixtures – TTM

Best-Selling Machining Fixtures - Gom fixture For Fender ,Casting Aluminium Parts Checking Fixtures – TTM Detail:

Specification

|

Fixture Type: |

Assembly Carbon Fibre Part Checking Fixtures |

|

Size: |

1600*1100*1000 |

|

Weight: |

95KG |

Detailed Introduction

The utility model discloses a physical examination tool for automobile front fender, which relates to the technical field of automobile front fender body detection. In order to solve the problem that the physical examination tool for automobile front fender on the market can only detect the front fender of a specific vehicle, and the limitation is too obvious, which is not conducive to large-scale promotion. Stated at the bottom of the setting of the top of the frame has a mounting plate, referred to the top of the mounting plate set a regulating block, described in the positioning block and the adjustment holes through the positioning bolt connection mutually, described in regulating side fixed link at the top of the block is installed, described in the regulating block the other side of the upper end fixed connected with one end of the spring, as described in the top set has a rotating rod end of the installation seat, The other end of the rotating rod is fixedly connected with one end of the splint, the other end of the splint is fixedly connected with the other end of the spring, the inner part of the splint is arranged between the rotating rod and the spring is provided with a positioning pin, and the inner part of the placement box is provided with a feeler.

The Working Flow

1. Received the purchasing order -——-> 2. Design -——-> 3. Confirming the drawing/solutions -——-> 4. Prepare the materials -——-> 5. CNC -——-> 6. CMM -——-> 6. Assembling -——-> 7. CMM-> 8. Inspection -——-> 9. (3rd part inspection if need) -——-> 10. (internal/customer on site) -——-> 11. Packing(wooden box) -——-> 12. Delivery

Manufacturing Tolerance

1. The Flatness of Base Plate 0.05/1000

2. The Thickness of Base Plate ±0.05mm

3. The Location Datum ±0.02mm

4. The Surface ±0.1mm

5. The Checking Pins and Holes ±0.05mm

Product detail pictures:

Related Product Guide:

Innovation, excellent and reliability are the core values of our firm. These principles today more than ever form the basis of our success as an internationally active mid-size corporation for Best-Selling Machining Fixtures - Gom fixture For Fender ,Casting Aluminium Parts Checking Fixtures – TTM , The product will supply to all over the world, such as: Barbados, Ireland, Malaysia, As an experienced factory we also accept customized order and make it same as your picture or sample specifying specification and customer design packing. The main goal of the company is to live a satisfactory memory to all the customers,and establish a long term win-win business relationship. For more information,please contact us. And it's our great pleasure if you like to have a personally meeting in our office.

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!

.png)

.png)