Best quality CNC Turned Components - TTM specializes in Customized machine/equipment design, mechanical engineering and production of turnkey automation systems. – TTM

Best quality CNC Turned Components - TTM specializes in Customized machine/equipment design, mechanical engineering and production of turnkey automation systems. – TTM Detail:

Application Fields

Automotive industry quality control

Automotive production line production capacity improve

Specification

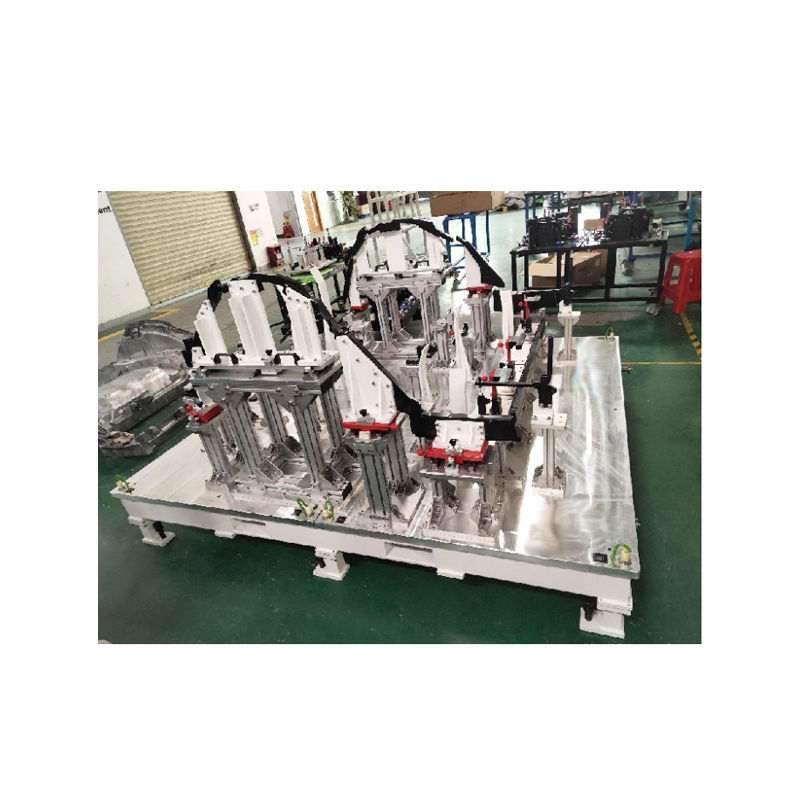

|

Fixture Type: |

Custom Special Purpose Tooling |

|

Size: |

1800x1300x900mm |

|

Weight: |

65KG |

Product Details

Detailed Introduction

1 Seat belt mounting nuts and nut plates are transported through vibration plates

2. The automatic mechanism is transferred to the nut assembly turntable for automatic assembly, stamping and fixing

3 Limit buckle, buckle strengthening plate, through the vibration plate conveying

4 Automatic transmission mechanism to the limit assembly rotary plate automatically assembled, coated with lubricating oil

5 Buckle toggle block through the vibration plate, the robot grab to the limit buckle

Robot will grab the limit assembly to the slider assembly turntable

7 Slider through the vibration plate transmission, automatic transmission mechanism to the slider assembly turntable

8. Limit assembly installation is completed by automatic mechanism on slider turntable

9 Buckle reset spring through the pipeline to the slider assembly turntable

10. The robot gripper completes the spring installation on the slider assembly turntable

The robot gripper grabs the NUT assembly onto the slider assembly turntable

12 Install the nut assembly automatically on the slider assembly turntable

13 Grab the slider assembly to the slider assembly turntable through the servo slide rail

14 Slide rails are delivered through belts

15 Robot will grab the slide rail to the slide rail assembly

16. The slide block is installed by automatic mechanism on the slide rail assembly turntable

17 Slider reset spring installation block through the vibration plate conveying

18 Automatic transmission to the mounting block to the slide rail assembly turntable

19 Slider reset spring is delivered through the belt

20 The vision system reads the direction and sends it to the robot, and the robot grasps the slide rail assembly turntable

Spring installation is completed by automatic mechanism on slide rail assembly turntable

22 The robot will grab the slide rail assembly into the detection and conveying mechanism

23 Automatic mechanism to complete the slide rail assembly stroke, strength detection

24 Guide rail installation screws are transported through the vibration plate

25 screws are delivered to the testing and conveying mechanism through the conveying pipe

26 Automatic mechanism installs the screw into the slide rail

27 Automatic conveyor mechanism will transport the belt slide rail assembly to the belt conveyor outlet

28 Finished product receiving

Lead time & Packing

45 days after 3D design approved

5 days via express: FedEx by Air

Standard Export Wooden Case

We will add fixing wooden block inside cases to make sure fixture safety in shipping. Desiccant and plastic wrap will be used to keep the checking fixture from moisture in shipping.

Product detail pictures:

Related Product Guide:

Assume full duty to satisfy all demands of our clients; reach steady advancements by marketing the development of our purchasers; grow to be the final permanent cooperative partner of clientele and maximize the interests of customers for Best quality CNC Turned Components - TTM specializes in Customized machine/equipment design, mechanical engineering and production of turnkey automation systems. – TTM , The product will supply to all over the world, such as: Dominica, New Zealand, Uruguay, Our market share of our products has greatly increased yearly. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future. We are looking forward to your inquiry and order.

Although we are a small company, we are also respected. Reliable quality, sincere service and good credit, we are honored to be able to work with you!

1.png)

.png)

.png)