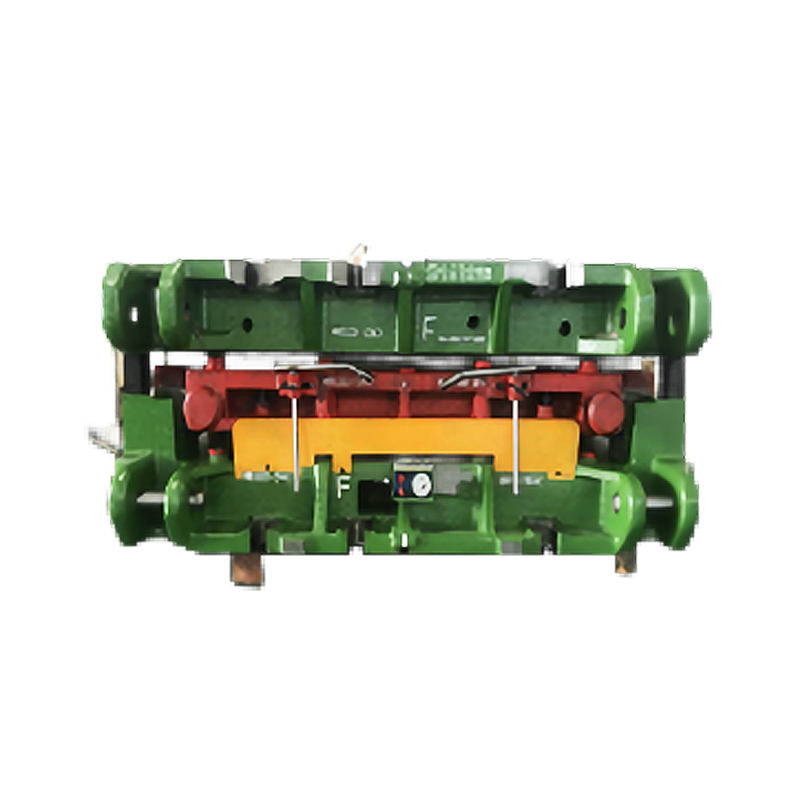

8 Year Exporter Stamping Parts Checking Fixture - Automotive Inspection Car Cross Beam Checking Fixture – TTM

8 Year Exporter Stamping Parts Checking Fixture - Automotive Inspection Car Cross Beam Checking Fixture – TTM Detail:

Function

For Car Cross Beam quality inspection control and support to improve the automotive production line capacity rate.

Application Fields

Automotive industry quality control.

Automotive production line production capacity improve.

Specification

|

Fixture Type: |

Car Cross Beam Checking Fixture |

|

Size: |

2850x950x1400 |

|

Weight: |

315 KG |

|

Material: |

Main Construction: metal Support: metal |

|

Surface treatment: |

Base Plate: Electroplating Chromium and Black Anodized |

Detailed Introduction

CX430 checking fixture has high measurement accuracy, no fear of deformation, low maintenance cost and good convenience. Key product characteristic inspection, characteristic line inspection, function hole inspection, area detection which is prone to deformation in assembly process, for automobile assembly and production function matching inspection. In the production process of automotive parts, on-line inspection of automotive parts is realized, which ensures the rapid judgment of the quality status of automotive parts in production, ensures the safety and processing speed of automotive assembly, and improves the quality of automotive parts.

The Working Flow

1. Received the purchasing order and Data/Standard/Requirement -——-> 2. Design -——-> 3. Review and approve design with customer -——-> 4. Prepare the materials -——-> 5. CNC -——-> 6. CMM -——-> 7. Assembling -——-> 8. CMM -——-> 9. Inspection(Dry fit) -——-> 10. (3rd part inspection if need) -——-> 11. Buyoff(internal/customer on site) -——-> 12. Packing(wooden box) -——-> 13. Delivery

Product Details

Manufacturing Tolerance

1. The Flatness of Base Plate 0.05/1000

2. The Thickness of Base Plate ±0.05mm

3. The Location Datum ±0.02mm

4. The Surface ±0.1mm

5. The Checking Pins and Holes ±0.05mm

Process

CNC Machining(Milling/Turning), Grinding

Electroplating Chromium and Black Anodized Treatment

Design Hours(h): 40h

Build Hours(h): 150h

Quality Control

CMM (3D Coordinate Measuring Machine), Vms-2515G 2D Projector, HR-150 A Hardness Tester.

Third Party Certification done by ShenZhen Silver Basis Testing Technology Co., Ltd , ISO17025 Certified.

Lead Time & Packing

45 days after 3D design approved

5 days via express: FedEx by Air

Standard Export Wooden Case

We will add fixing wooden block inside cases to make sure fixture safety in shipping. Desiccant and plastic wrap will be used to keep the checking fixture from moisture in shipping.

Product detail pictures:

Related Product Guide:

Our commission should be to provide our end users and clients with very best excellent and aggressive portable digital products and solutions for 8 Year Exporter Stamping Parts Checking Fixture - Automotive Inspection Car Cross Beam Checking Fixture – TTM , The product will supply to all over the world, such as: Afghanistan, Maldives, Johannesburg, Based on experienced engineers, all orders for drawing-based or sample-based processing are welcomed. We have now won a good reputation for outstanding customer service among our overseas customers. We will continue to try the best to supply you good quality products and solutions and the best service. We've been looking forward to serving you.

It can be said that this is a best producer we encountered in China in this industry, we feel lucky to work with so excellent manufacturer.

.png)

.png)