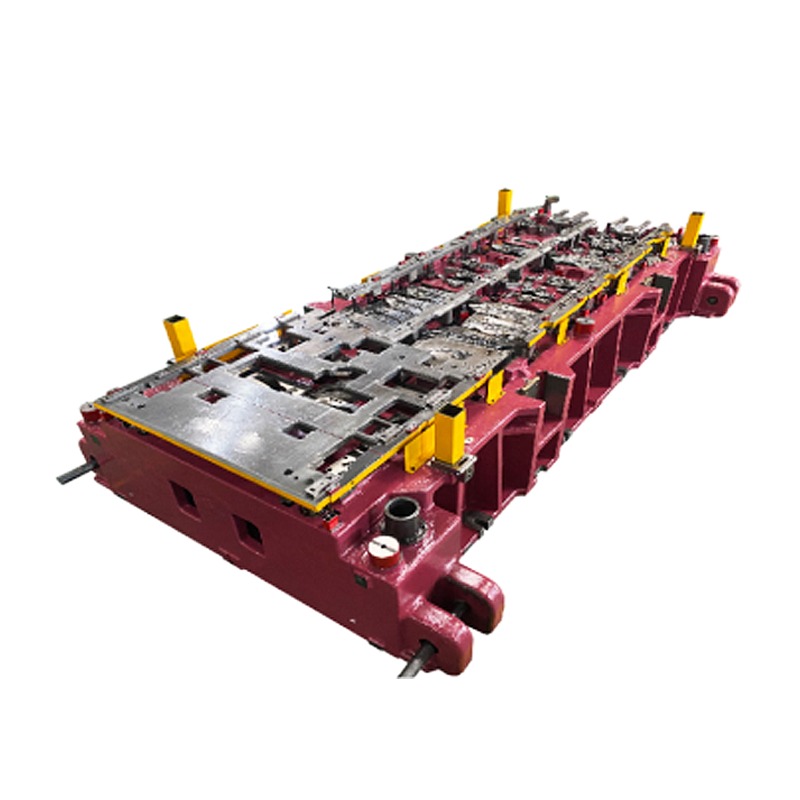

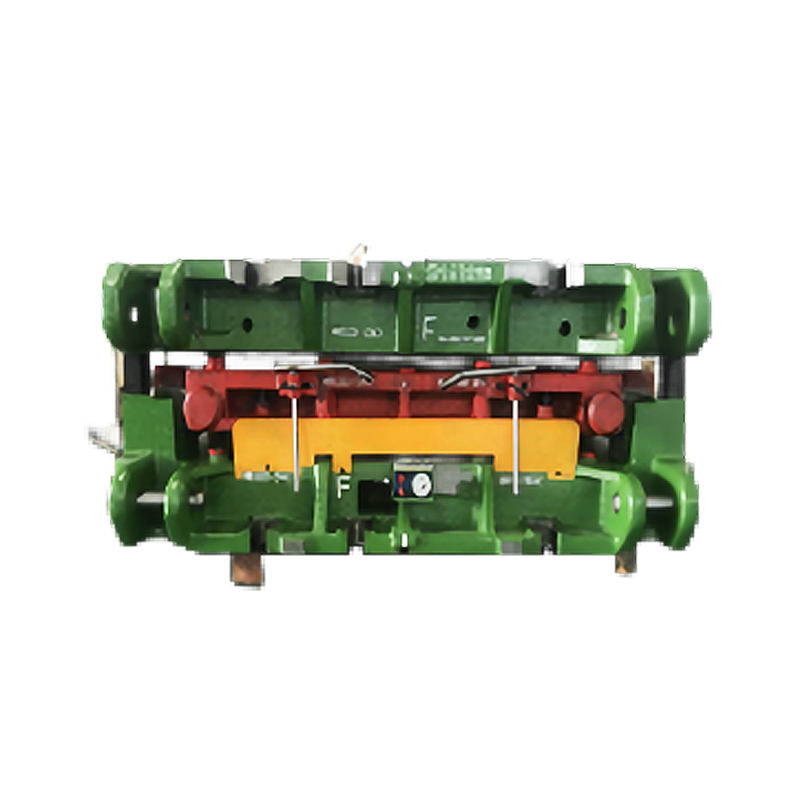

8 Year Exporter Stamping Parts Checking Fixture - Assembly CF for Metal Stamping Part – TTM

8 Year Exporter Stamping Parts Checking Fixture - Assembly CF for Metal Stamping Part – TTM Detail:

Function

For car quality inspection control and support to improve the automotive production line capacity rate.

Specification

|

Fixture Type: |

Assembly CF for Metal Stamping Part |

|

Size: |

1850x950x1100 |

|

Weight: |

1950 KG |

|

Material: |

Main Construction: metal Support: metal |

|

Surface treatment: |

Base Plate: Electroplating Chromium and Black Anodized |

Product Details

Detailed Introduction

Our company supplies different kinds of products. High quality and favorable price. We′re pleased to get your Inquiry and we will come back to as soon as possible. We stick to the principle of “quality first, service first, continuous improvement and innovation to meet the customers” for the management and “zero defect, zero complaints” as the quality objective. To perfect our service, we provide the products with good quality at the reasonable price.

We can provide following OEM one-stop services:

Die Design & Open

We use the most advanced die design software Auto CAD, Solid-works, UG (dwg), we open dies and tools ourselves.

Our Capabilities:

We use advanced technology, unmatched skill, professional equipment and rich experience technicians to fit our customers′ requirements, like tooling manufacturing, stamping, deep drawing, welding, tube bending and surface coating service

Range of Materials:

Metal sheets include carbon steel, stainless steel, alloy steel, aluminum, copper, etc.

Range of Material Thickness:

It is 0.2-10mm for punching, stamping, forming, no thickness limit for welding.

Processing Range:

Progression die, Cutting, Stamping, Deep drawing, Bending, Punching, Threading, Welding, Tapping, Riveting, Grinding

Surface Range:

Plating(zinc, nickel, chrome), electroscopes, painting, powder coating, electrostatic spraying, hot DIP galvanized, dacromet, anodize oxidation, blacking, polishing, anti-rust oil

Packaging & Delivery

Our products are all packed in strong cartons and pallets/wooden cases to ensure zero damage. If customers have specific requirements for the packaging, we will gladly accommodate. The products can be sent to you by sea or by plane.

Lead Time & Packing

1. Received the purchasing order -——-> 2. Design -——-> 3. Confirming the drawing/solutions -——-> 4. Prepare the materials -——-> 5. CNC -——-> 6. CMM -——-> 6. Assembling -——-> 7. CMM-> 8. Inspection(Dry fit) -——-> 9. (3rd part inspection if need) -——-> 10. Buyoff(internal/customer on site) -——-> 11. Packing(wooden box) -——-> 12. Delivery

Product detail pictures:

Related Product Guide:

Our commission should be to provide our end users and clients with very best excellent and aggressive portable digital products and solutions for 8 Year Exporter Stamping Parts Checking Fixture - Assembly CF for Metal Stamping Part – TTM , The product will supply to all over the world, such as: Cambodia, Haiti, Philippines, Our tenet is "integrity first, quality best". We have confidence in providing you with excellent service and ideal products. We sincerely hope we can establish win-win business cooperation with you in the future!

Managers are visionary, they have the idea of "mutual benefits, continuous improvement and innovation", we have a pleasant conversation and Cooperation.

.png)

.png)