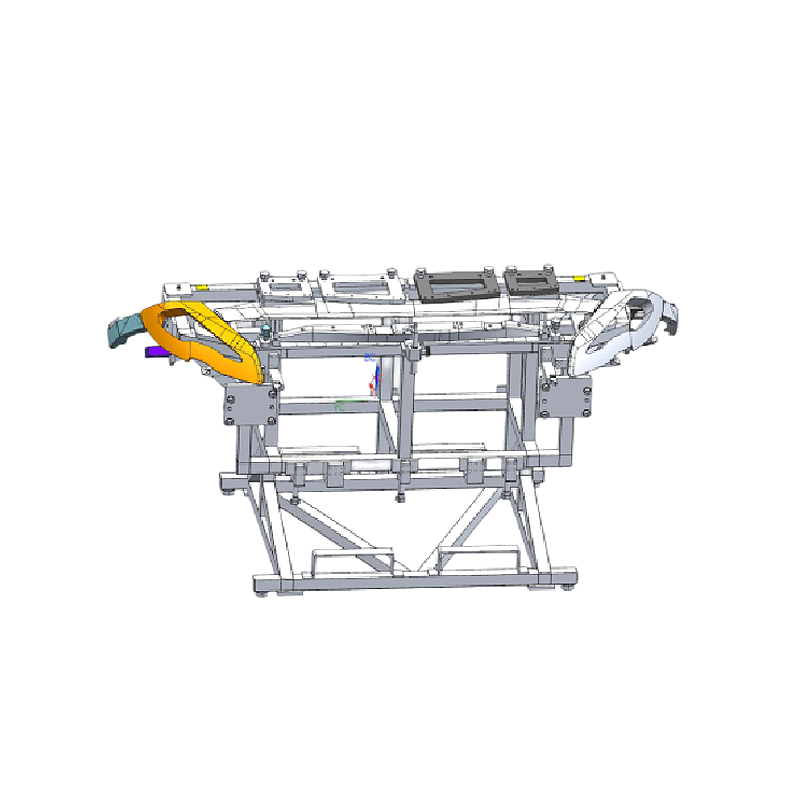

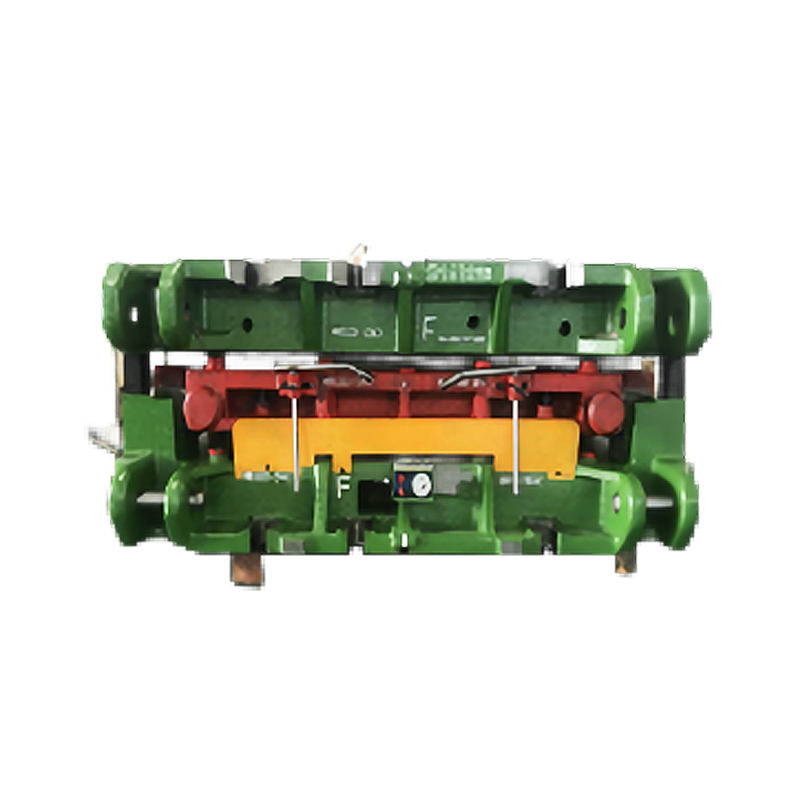

100% Original Control Fixture - Carbon Fibre Checking Fixtures for car door – TTM

100% Original Control Fixture - Carbon Fibre Checking Fixtures for car door – TTM Detail:

Function

For Carbon Fibre quality inspection control and support to improve the automotive production line capacity rate.

Application Fields

Automotive industry quality control

Automotive production line production capacity improve

Specification

|

Fixture Type: |

Assembly Carbon Fibre Part Checking Fixtures |

|

Size: |

1800x1300x900mm |

|

Weight: |

55KG |

Advantages

These are needed in many areas of our fixture, our electronic industry and machinery industry, in particular, it is a clear standard for the size of the product, the fixture can very good help we could check staff, that with the excellent performance of carbon fiber composites, the fixture on the market also appeared a lot of carbon fiber composites of carbon fiber fixture, on the new material to talk about the three advantages of carbon fiber tester.

Advantage one: excellent machining performance

Submit the first requirement is to have good precision, such ability in the us in practice, better guarantee the performance advantages of itself, the carbon fiber fixture, have excellent plasticity, after forming, also has the very strong rigid demand, at the request of the special fixture, such as resistance to high temperature performance, The carbon fiber tester will not expand even in the high temperature environment, which ensures the stability of the carbon fiber tester and the accuracy of the tester.

Advantage two: stiffness performance is very good

Because of the special performance of carbon fiber composite material, the stiffness of carbon fiber test tool is better, the stiffness is several times of the traditional steel, the stiffness of carbon fiber test tool also makes carbon fiber can have better tensile strength and shear strength, and the higher the grade of carbon fiber mechanical performance is more obvious.

Advantage three: lighter quality

One of the most obvious characteristics of carbon fiber composite products is lighter weight. Carbon fiber composite material has very good weight reduction performance, with less than a quarter of the weight of steel, it is more convenient to use, which can well ensure its convenience. Under such circumstances, the inspection tool is easier to carry.

The Working Flow

1. Received the purchasing order -——-> 2. Design -——-> 3. Confirming the drawing/solutions -——-> 4. Prepare the materials -——-> 5. CNC -——-> 6. CMM -——-> 6. Assembling -——-> 7. CMM-> 8. Inspection -——-> 9. (3rd part inspection if need) -——-> 10. (internal/customer on site) -——-> 11. Packing(wooden box) -——-> 12. Delivery

Lead time & Packing

30 days after 3D design approved

5 days via express: FedEx by Air

Standard Export Wooden Case

Product detail pictures:

Related Product Guide:

We try for excellence, service the customers", hopes to be the most effective cooperation workforce and dominator company for staff, suppliers and shoppers, realizes price share and ongoing marketing for 100% Original Control Fixture - Carbon Fibre Checking Fixtures for car door – TTM , The product will supply to all over the world, such as: Poland, Dubai, El Salvador, All these products are manufactured in our factory located in China. So we can guarantee our quality seriously and availably. Within these four years we sell not only our products but also our service to clients throughout the world.

We are a small company that has just started, but we get the company leader's attention and gave us a lot of help. Hope we can make progress together!

.png)

.png)